Mounting of the Winch

MOUNTING INSTRUCTIONS

1. Be sure that the mounting surface is of

sufficient strength to support a load well

in excess of the rated winch capacity.

2. Fasten the winch to the mounting surface

with three 1⁄2” bolts, nuts, washers and

lockwashers. Be sure that the winch is

positioned so that the cable does not rub

the front opening of the winch.

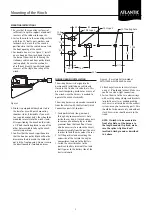

3. For double line use (see Figure 3), install

an eye hook on the winch stand close to

the base of the winch for fastening the

stationary cable hook from pulley block

(not supplied) Be sure the eyehook is

of sufficient strength to withstand loads

in excess of the single line rating of the

winch.

Figure 3

4. Winch is equipped with keyhole slots in

the base for use with quick mounting

shoulder studs, if desirable..If you wish

to use quick mount studs, they should be

mounted securely into the winch stand.

After positioning the winch on the studs,

a 3/8”bolt should be placed in one of the

other holes available to keep the winch

securely in position.

5. Confirm that the winch is positioned so

that the hook or pulley block will not be

drawn into the drum and the cable will

not rub the front opening. Do not reverse

the direction cable if wound on drum.

WIRING HARNESS INSTALLATION

The wiring harness is designed to be

permanently installed on a vehicle and

stored in the trunk or truck bed, etc. This

prevents tampering, accident or misuse of

the winch since the harness is needed to

operate the winch electrically.

The wiring harness can be made re movable

from the vehicle with the Electrical Quick

Connect(see parts list to order).

1. Feed positive lead (long) wire only

through any convenient access hole

inside the car trunk. It may be necessary

to remove a knockout plug or rubber

grommet from the trunk floor. It may

also be necessary to remove the circuit

breaker assembly from the positive wire

in order to feed the wire under the car.

2. Pull the positive lead wire along the

underside of the car into the engine

compartment and up to the battery.

3. Fasten the circuit breaker to the

po)battery terminal(if nut and

bolt type )or to the battery side of the

starter solenoid.

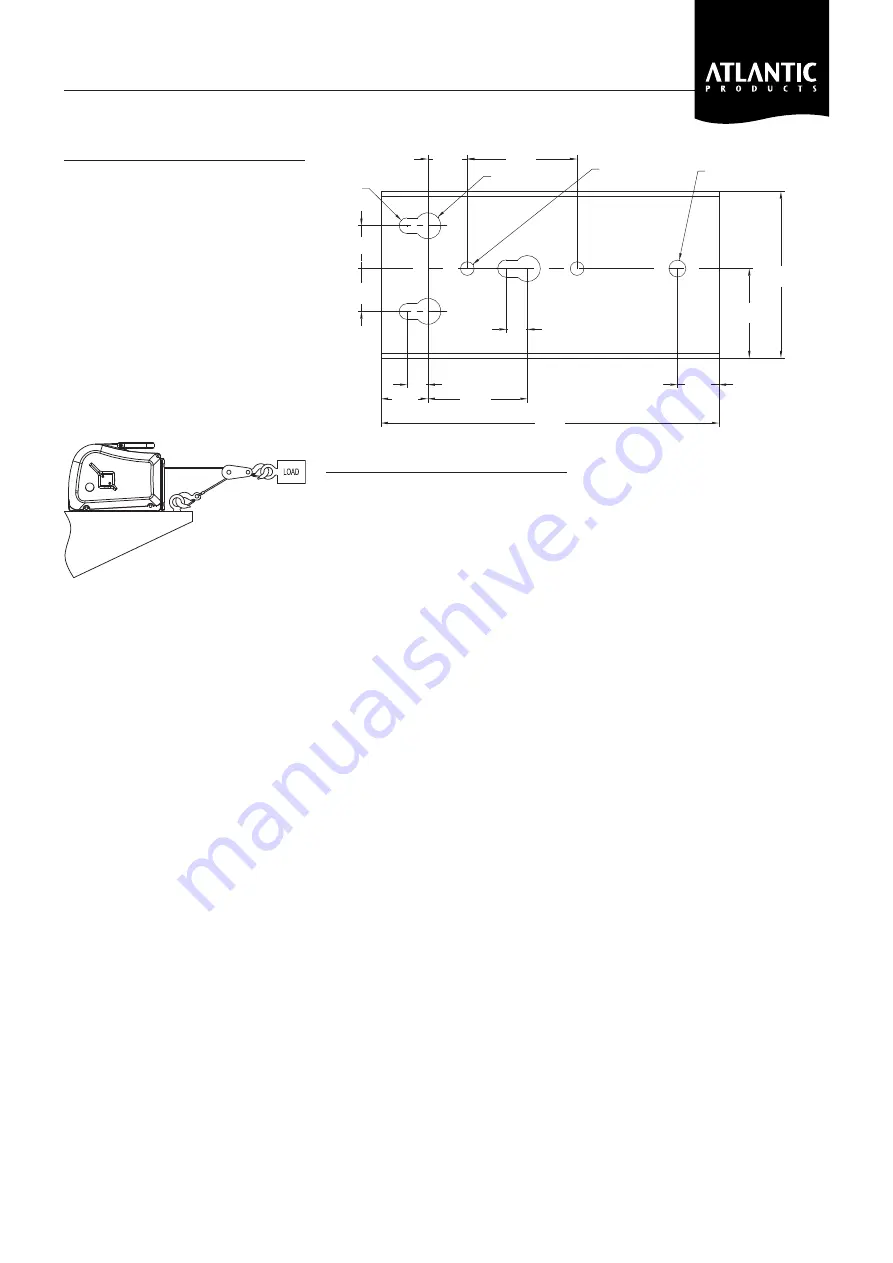

Figure 4 - Base Hole Pattern-Model

EMW1500R & EMW3000R (in mm)

4. Attach negative wire to vehicle frame

using a 1/4”bold and locknut. Make sure

you have a clean, tight connection.

5. Fasten the wire to the car undercarriage

with existing wiring clamps and brackets,

(or plastic wire ties as needed)making

sure wire is not located near the exhaust

system, or any hot or moving parts. Wire

should be fastened securely and without

slack. Excess wire should remain in the

trunk.

NOTE: If winch is to be mounted in

front of vehicle, cut the harness to

the length needed. If spliced, make

sure the splice is tight and well

insulted. Attach ground as described

in 4 above.

30

35

15.8

15.8

76.2

257

51

110.5

31.75

31.75

31.75

84

19.8 type 3

13.5

type 3

10.3 type 2

12.7 tooling hole

3