19

S

S

t

t

a

a

r

r

t

t

-

-

u

u

p

p

Check

that the machine is completely and correctly as-

sembled.

Before using the log splitter

, make sure each time that

−

there are no faulty connections (tears, cuts, etc.)

−

there are no damage at the machine

−

all screws are tight

−

check the hydraulic system for any possible leaks

−

the oil level

Venting:

Vent the hydraulic system before putting the log

splitter into operation.

¾

Unscrew venting cap (14) by several turns so that air

may escape from the oil tank.

¾

Leave the cap open during operation.

¾

Close the venting cap before moving the log splitter, as

o herwise oil will leak at this point.

t

L

If the hydraulic system is not vented, the trapped air will

damage the seals and cause permanent damage to the

log splitter.

L

Mains connection

Compare the voltage given on the machine model plate

e.g. 230 V with the mains voltage and connect the ma-

chine to the relevant and properly earthed plug.

Only use

connection cables

with sufficient diameters.

Connect the machine via a 30 mA RCD (residual current

operated device).

L

Fuse protection

230 V~

Î

16 A inert

400 V 3~

Î

10 A inert

L

Switching on / off

Switching on

1

Press the green button.

Switching off

Press the red button.

Prior to every use,

check the function of the disconnection mechanism (by

switching on and off).

L

Lock in case of power (zero-voltage ini-

tiator)

The equipment will switch off automatically if there is a power

cut. Repress the green button to switch it on again.

Log splitter with 400 V 3~

Make sure that the motor turns in the correct direction

(see arrow on the motor), because operation in the wrong

direction damages the oil pump.

Checking the direction of rotation

:

¾

Switch on motor; the splitting blade automatically moves to

the highest position.

¾

If the splitting blade is already in its highest position: grip

both operating handles and push them down. The splitting

blade moves downwards.

¾

If the splitting blade does not move after the motor has

started, switch off the motor and change the direction of

rotation.

You can change the

direction by placing a

screwdriver in the slot

provided in the plug

collar, and adjust the

correct direction by

moving to the left or

right applying slight

pressure.

L

Hydraulics

Never operate the machine in the event of any possible

danger from hydraulic fluid.

Ensure that the machine and working area are clean and

free of oil.

Danger of slippage or fire!

Check the hydraulic reservoir regularly to ensure that it

contains enough hydraulic oil (see “Care and mainte-

nance”)

Capacity: 6.0 litres

Содержание ASP 6-1050

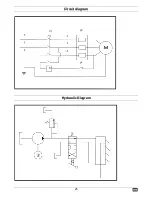

Страница 15: ...14 S Sc ch ha al lt tp pl la an n H Hy yd dr ra au ul li ik kp pl la an n ...

Страница 26: ...25 C Ci ir rc cu ui it t d di ia ag gr ra am m H Hy yd dr ra au ul li ic c D Di ia ag gr ra am m ...

Страница 37: ...36 S Sc ch hé ém ma a d de es s c co on nn ne ex xi io on ns s P Pl la an n h hy yd dr ra au ul li iq qu ue e ...

Страница 48: ...47 I In ns st ta al ll la at ti ie es sc ch he em ma a H Hy yd dr ra au ul li is sc ch h s sc ch he em ma a ...

Страница 59: ...58 K Ko op pp pl li in ng gs ss sc ch he em ma a H Hy yd dr ra au ul li ik ks sc ch he em ma a ...

Страница 70: ...69 S St tr rø øm mp pl la an n H Hy yd dr ra au ul li ik kp pl la an n ...