17

Chapter 5 Fault diagnosis

5.1 Summarize

Before repairing, you must cut the main switch or breaker.

。

If the machine can’t work normally, use following information, you can find the reason.

Check trouble and collate symptom, as table 5-1.If the problem can’t be found at once, you

should open the power to see ass parts and wire.

Electric repairing must be made by career man.

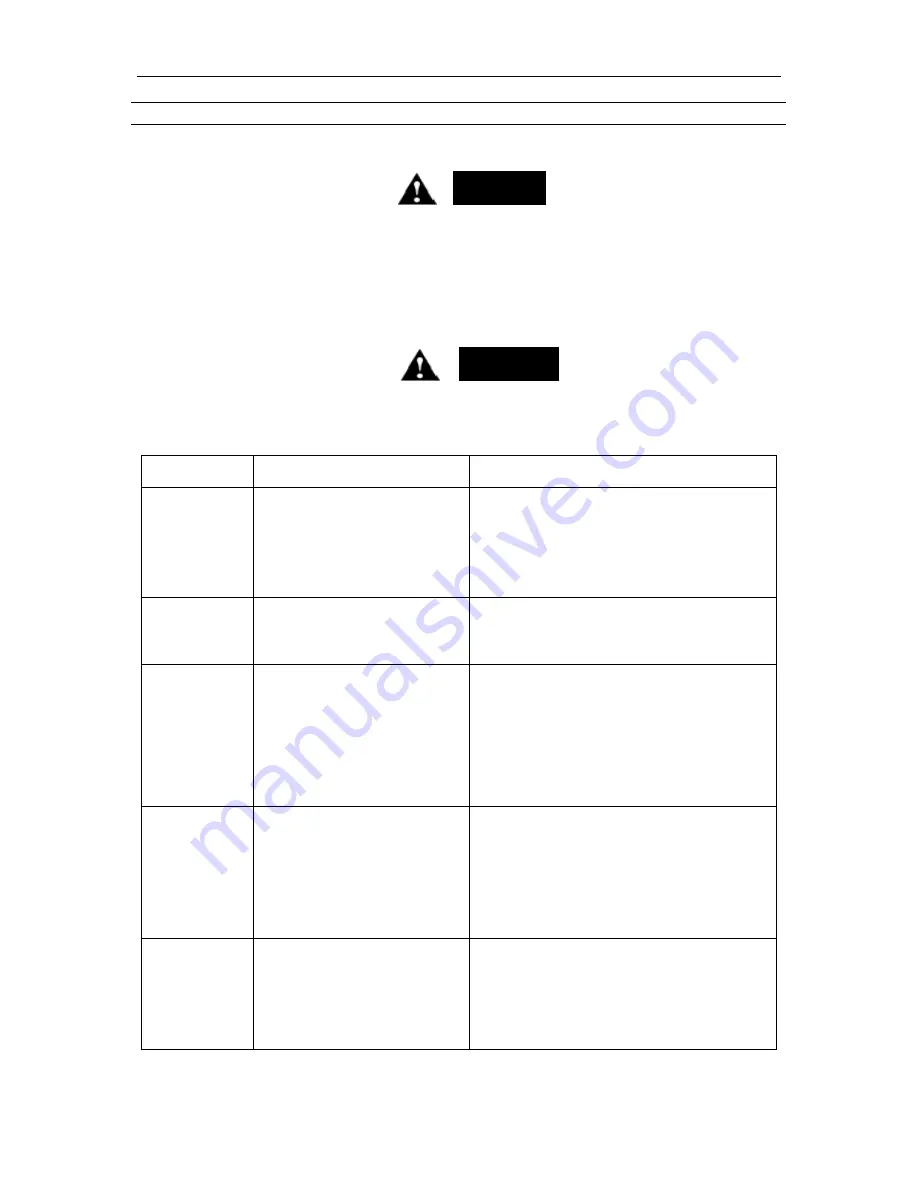

Table5-1 Diagnose and remove

TROUBLE REASON

SHOOTING

Welder dose

not function

when

switched on

1. No power at receptacle

2. Broken or damaged power

cable

3. Tripped thermal protection

device

1. Check circuit fuse or circuit breaker

2. Power cable requires service

3. After cooling then try to continue

Wire does not

feed properly

1. Insufficient wire feed

pressure

2. Wing nut is too loose

1. Increase wire feed pressure properly

2. Tighten wing nut

Welding arc

not stable

1. Heavy loads making power

line voltage low

2. Work piece not properly

grounded

3. Incorrect wire feed speed

1. Run welder on rated line voltage

2. Verify proper grounding. (No paint,

varnish or corrosion)Replace by career.

3. Adjust wire feed speed to achieve a more

stable arc

The weld is

like sponge

1. Empty gas cylinder.

2. Regulator or cylinder valve

closed.

3. Nozzle plugged.

4. Gas line blocked.

1. Check gas cylinder

2. Make sure both valves are adjusted

properly

3. Clean nozzle, if damaged, replace.

4. Check external hose, and hose within

Torch cable.

When

Pressing

switch the

machine can

not working

1. Control wire broke off

2. Circuit board damaged.

1. Check by career

2. Have a qualified technician check or

replace

Warning

Warning