Operation Manual Touchscreen

11. NETWORKING CONFIGURATION

ATTENTION: The user can only use the configuration menu for the settings described in this manual.

Any further changes can lead to a malfunction!

The drying cabinet or drying unit is pre-configured from the factory with the following IP settings. To

establish a connection to your network, the address configuration must be adapted accordingly.

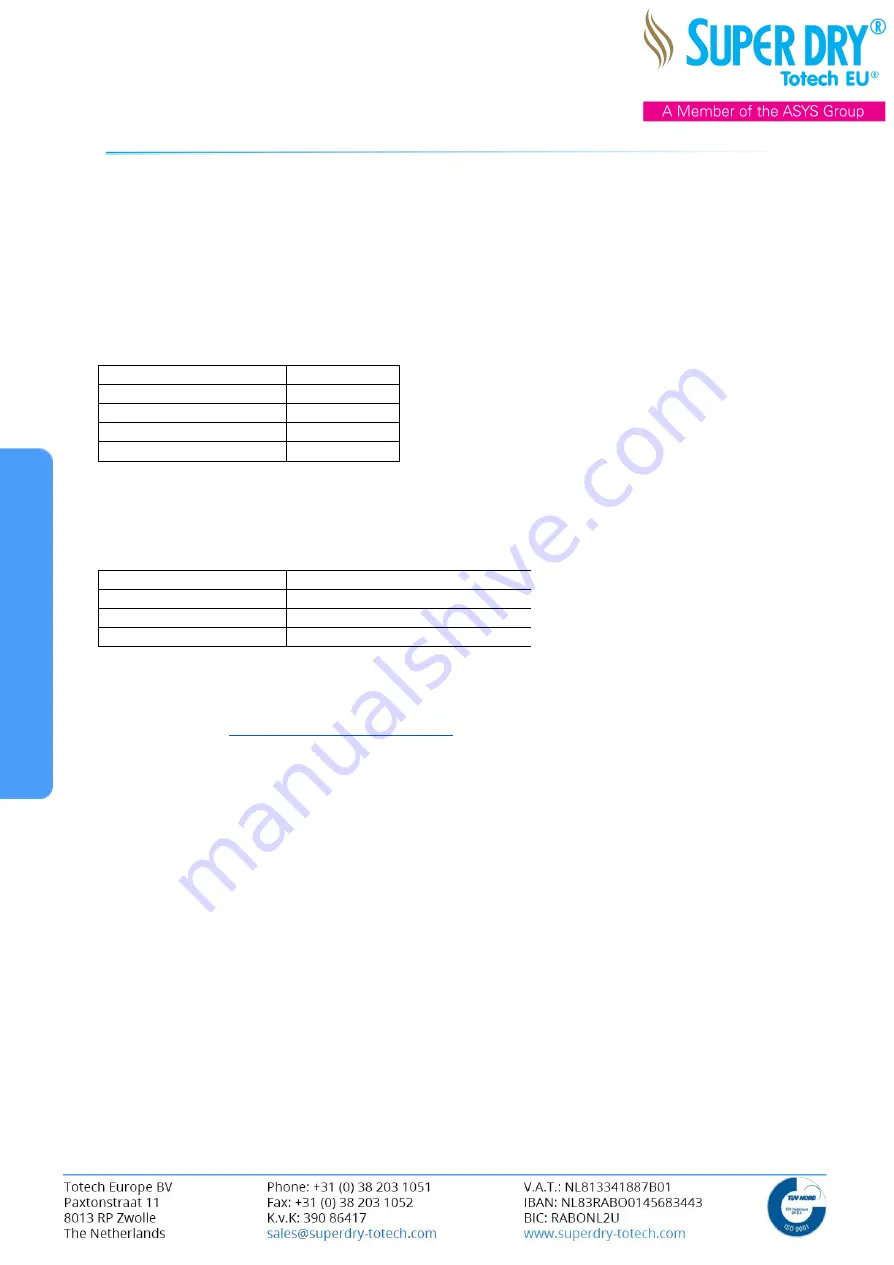

Factory default settings:

Component

Address

BM (LOGO! Base module) 10.31.0.xxx

TDE (LOGO! Display)

10.31.0.xxx

Subnet

255.255.255.0

Gateway

10.31.0.1

11.1 CHANGE THE IP ADDRESS OF THE LOGO! BASE MODULE

To integrate the cabinet into your network, proceed as follows:

Before starting with this procedure, please determine 2 IP addresses which can be used for the

cabinet in your local network, and write them down:

Component

Address

BM (LOGO! Base module)

TDE (LOGO! Display)

Subnet

Gateway

If you do not know which IP addresses can be used, please ask your local IT administrator.

To change the IP address of the LOGO! Base module, you’ll need to download our free Totech Viewer

from our website:

http://www.superdry-totech.com/

For the following steps, you’ll need to have the cabinet connected to the network. You can also

connect the cabinet directly to a PC or laptop using an Ethernet cable. Make sure that the PC or laptop

running the Totech Viewer software is set in the same range as the current IP address of the cabinet

before changing the IP address, or it won’t work:

Open the software, press [File]

→

[Download data]

→

[Refresh]

The software will show the current IP address of the cabinet.

Right click on the IP address

→

[Change IP address]

Change the addresses in the pop-up window and confirm with [OK]

Press [Refresh] again and the cabinet should show up with the new set IP address.

11.2 CHANGE THE IP ADDRESS OF THE DISPLAY

The IP address in the display must also be adapted for communication with the LOGO control. The IP

address of the LOGO! Base module and the display must be in the same subnet.

To do this, go to the [Setting] menu on the 3rd page and press [Offline].

After a few seconds, the home menu of the display will be displayed.

Now proceed in the following order:

Press [Main Unit]

→

[Ethernet]

⇒

The IP address for the display can be changed here.

Follow up with pressing [Back]

→

[Save]

→

[Yes]

→

[Exit]

→

[Yes]

The [Port] number specified here is used for setup via Ethernet, for transfer of project files, and for

communication with Pro-Server EX. Do not change the initial value [8000].

Содержание Totech EU SUPER DRY U-5003 I-3315003

Страница 13: ... Operation Manual Touchscreen ...