02.06.2022 V1

Page 2

2. SPECIFICATIONS AND OPERATING ENVIRONMENT

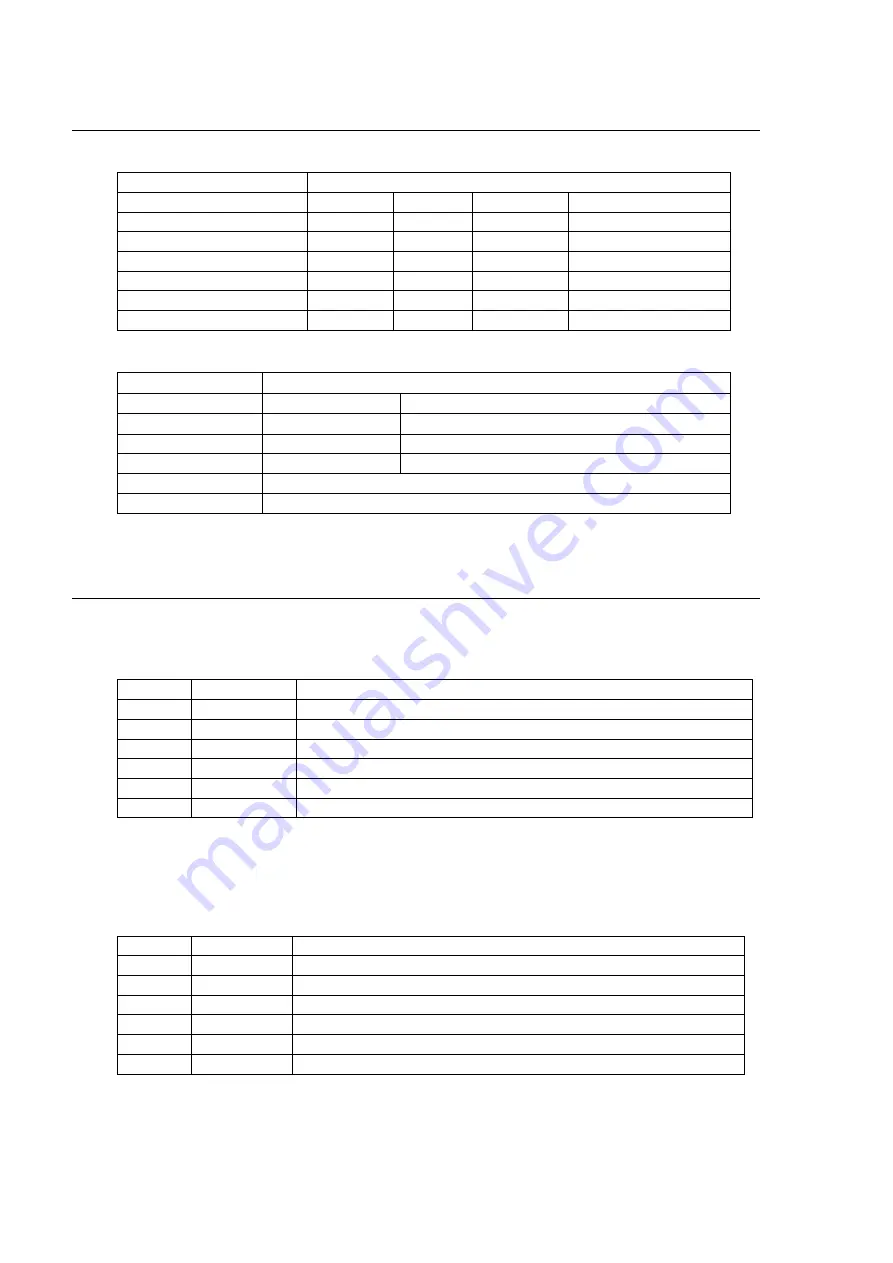

Electrical Specifications (T = 25

C)

Parameters

Min

Typical

Max

Remark

Peak Output Current

2.8A

By user

8.4A

By DIP Switch

Supply Voltage (DC)

25Vdc

36Vdc

110Vdc

Supply Voltage (AC)

18Vac

24Vac

80Vac

Logic Signal Current

6mA

10mA

30mA

Pulse Input Frequency

0 Hz

By user

200 kHz

Minimum Pulse Rate

2.5µs

Operating Environment and Parameters

Coolant

Heatsink and fan if operating temp. exceeds 80

C

Environment

Space

Avoid dust, oil, frost and corrosive gases

Temperature

0

C to 50ºC

Humidity

40% to 90%RH

Vibration

5.9m/s

2

Max

Storage Temp.

-20 ºC to +65ºC

Weight

Approx 600g

3. DRIVER CONNECTORS, P1, P2 and P3

The following is a brief description of the three connectors of the drive.

Control Signal Connector P1 Pins

Pin No.

Signal

Functions

1

Direction -

Triggers change in direction of rotation

2

Dir

Connect to +5Vdc

3

Pulse -

Triggers motor to move

4

Pulse +

Connect to +5Vdc

5

Connect to 0v to disable drive

6

Enable -

Connect to +5Vdc

Please note motion direction is also related to motor-drive wiring. Changing the

connection of two-wires for a coil to the drive will also reverse motion direction.

Power Connector P2 Pins

Pin No.

Signal

Functions

1

Phase A +

Motor coil A+

2

Phase A -

Motor coil A-

3

Phase B +

Motor coil B+

4

Phase A-

Motor coil B-

5

V+

Positive supply for dc or ac input

6

V-

Ground for dc or ac input

Please note that there is another connector for RS485 communication, which was a

feature offered for one particular OEM.