Chint Solar (Zhejiang) Co., Ltd. | Add:1335 Bin´an Road, Binjiang District, Hangzhou | P.C: 310053

Tel: 0086-571-5603 1888 | Fax: 086-571-5603 2316 | Website: http://energy.chint.com/

touch and drag on the ground.

c) After unpacking the modules should be installed that day as far as possible. It’s

recommended to take the right amount of modules according to the progress of the project

every day. Heavy rain and other inclement weather may have the potential to soak the

packaging which can affect product reliability, such as storms, typhoons, hurricanes or other

events in which they may be blown away. If the users need to store modules before

installation, do not open the package, the goods should be stored in a room temperature,

dark, dry and ventilated place.

1.3.2 Module’s Stack

a) When a module is taken out of the box, cardboard bedding below should be applied in order

to avoid contact with cement surface / ground, hard metal or tile. Modules should be placed

neatly and should not be dropped, slammed or scratched.

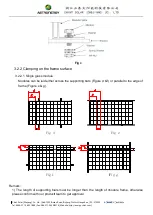

b) When stacking modules, it needs to be stacked neatly in the horizontal plane, under the

condition of the glass facing down and the back way piled up, while the cardboard bedding

need to be underside the modules. If the modules will be installed on the rooftop, the

number of each stack is suggested no more than 20. In case of the poor load-bearing

capacity, it’s recommended that the designer and/or installer check with the structural

engineer or architect to determine the amount of load allowable for specific location. During

the whole process, the installation tools and other objects must be prevented from

contacting the module surface.

c) If the modules are requested to be classified by current, the handling personnel are required

to carry out of the level of the current and make a mark separately according to the power

on the list. (e.g. 275W-L, identifies the modules of the packaging according to the power on

the list, indicating a low current position; 275W-H, compared to high current position).

Usually, the same series of modules in the same current position are required in

accordance with the system design requirements.

d) If the modules are color-coded and marked the corresponding logo on the carton due to the

customer requirements, when modules are taken out and stacked, they should be labeled to

avoid confusion. Usually the same row or the same square have the same color according

to the system design requirements.

e) Due to the complexity and difference of the construction site, these precautions may not