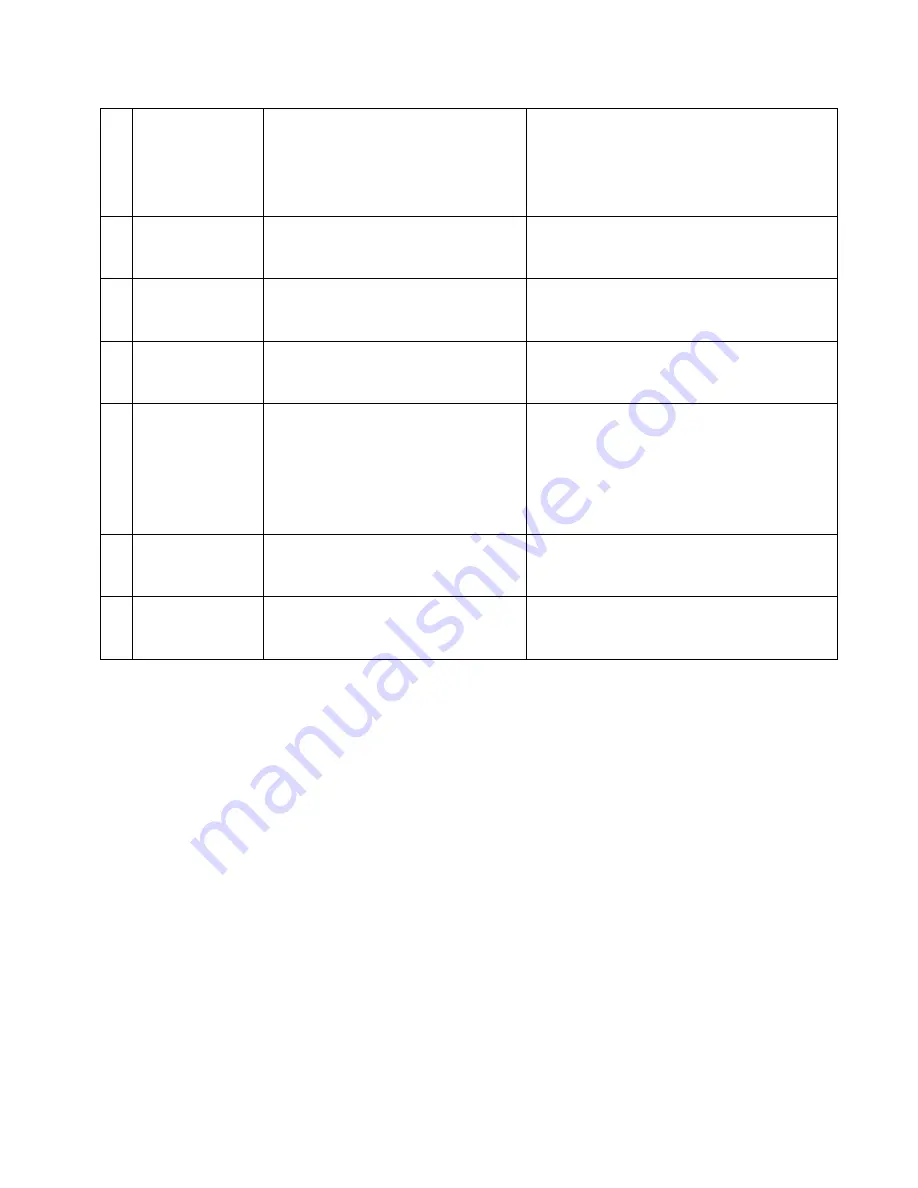

4

E

Charge Chamber

The air tight cone defines the

charge

chamber

while forming a conduit for

water transmission into and out of

the

charge chamber

In this design series, the charge chamber is

wrapped around the centralized conduit

which re-suspends and aerates sludge

during each backwash event

F

Air Inlet

Slowly fills the charge chamber with

air

Air is added at a slow rate so that it takes a

few hours to fill the

charge chamber

.

G

Trigger

Catastrophically releases air from

the charge chamber once it is filled

H

Diffuser

Redirects the incoming water

beneath the bead bed.

Hydraulically designed to minimize

turbulence that may erode the bed.

I

Sludge Basin

Provides for temporary sludge

storage.

The sludge that is released from the bead

bed during a backwash settles out of the

cone

and charge chamber that can be

removed periodically as a thick sludge

through the

sludge outlet

.

J

Sludge Outlet

Facilitates the removal for thickened

sludge from the unit.

Sludge is typically concentrated to 10,000-

20,000 mg/L in the HPPG series.

Cap

Directs flow from the

screen

to the

Outlet

pipe(s)

The

cap

assembly also includes gaskets that

seal the screen to the f

ilter hull.

Installation

Installation will require that you hook up a water pump to circulate water through the filtration bed and

an air compressor to fill the charge chamber for the back wash sequence. Filters in the HPPG series are

most frequently paired with a low head centrifugal pump capable of delivering a high rate of flow at

relatively low pressures (5-10 psi). However, in commercial scale recirculating aquaculture

applications, the units can be paired with airlifts to minimize energy consumption. Use of airlifts,

however, generally requires lowering (burying) the unit so water can be filtered by gravity and then

airlifted back up. With total filtration head losses beneath 0.5 psi, use of airlifts can be attractive

whenever the physical configuration permits.

The backwashing air source must be matched with the circulation method you select. Simply stated the

air pressure must exceed the water pressure for air to flow into the unit.

Pump Configuration

A self-siphoning, above ground, centrifugal water pump can be used to circulate water through an

HPPG. The unit should have a water delivery capacity of 10-15 gallons per minute for each cubic foot of