6

1-800-727-5477 • www.sargentlock.com

A8257E 4/22

7800 and 8200 Series Mortise Lock

Installation Instructions

Used with Sectional Trim and V Series Indicators

Copyright © 2019, 2020, 2021, 2022, SARGENT Manufacturing Company. All rights reserved. Reproduction in

whole or in part without the express written permission of SARGENT Manufacturing Company is prohibited. Patent

pending and/or patent www.assaabloydss.com/patents.

Installation, continued

5

g

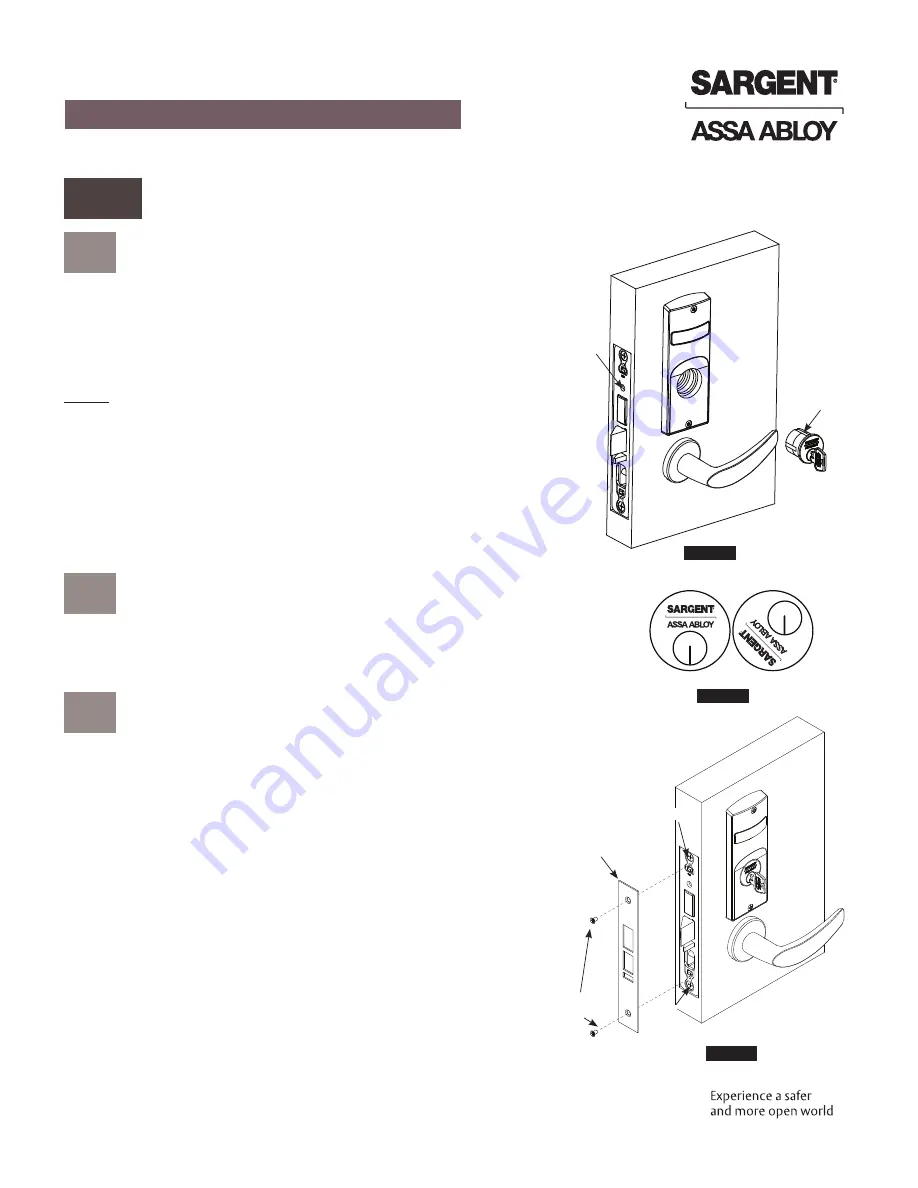

Install Cylinders

Cylinder

Cylinder

Clamp

Screw

Figure 11

Incorrect

Key and cylinder must be rotated as shown.

Correct

Figure 12

Figure 13

Lock screw

Outside front

#8-32 x 1/4"

screws

Lock

screw

1. Thread cylinder into lock until flush with escutcheon surface. (Figure 11)

• Pull key slightly out of cylinder to help thread into lock body.

2. Tighten cylinder clamp screw with #2 Phillips screwdriver.

• Check operation and adjust if necessary.

Notes:

•

SARGENT logo must be horizontal and on top. (Figure 12)

•

If double cylinder function is used, repeat steps 1 and 2 for second

cylinder.

•

Removable Core or Interchangeable Core cylinders

require a control key (key stamped with C) to remove and

install the core. This is not provided standard; it must be

requested separately. If requesting 1-bitted control key,

specify 113511 cut.

h

Install Outside Front

1. Tighten the two (2) lock screws completely: (Figure 13)

2. Attach outside front with two (2) flat head screws #8-32 x 1/4".

i

Perform Functional Check

DO NOT FORCE if resistance is encountered during functional

check. Refer back to Rehanding Indicator (if required) section to ensure

correct handing. Rehand if necessary.

1. Insert key into cylinder (if present) and rotate:

• Ensure there is no friction against lock case or any other

obstructions.

2. Check key retracts latch:

• Key should rotate freely.

3. Throw deadbolt (if present):

• Check key retracts both deadbolt and latch.

4. Test

levers:

• Confirm latch and deadbolt (if installed) retract.

5. Verify indicator displays correct status when locked and unlocked.