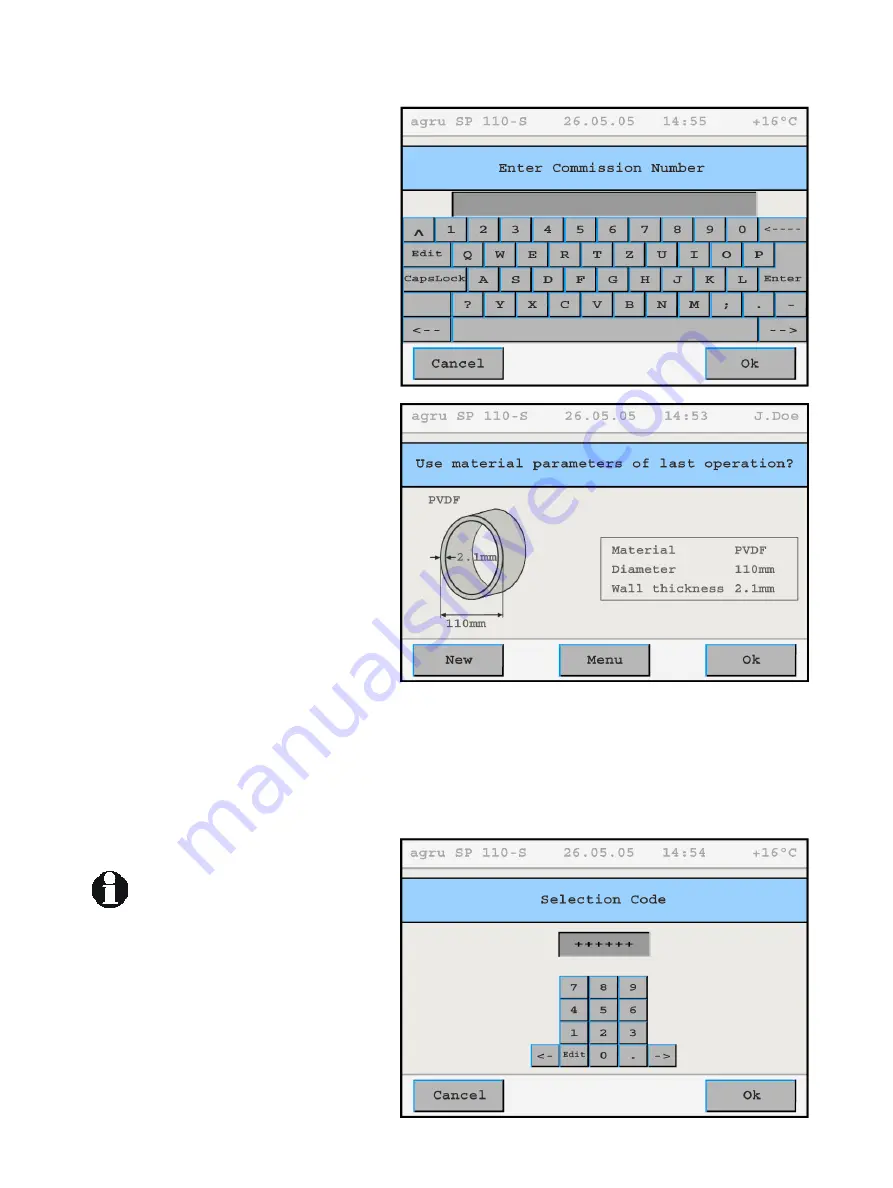

When the traceability data were entered, the machine displays the first input

screen of the welding process proper (see

Display 5). In this display, it is possible to

start the welding process and to customize

the configuration of the machine.

The welder will enter all settings and perform

all control actions on the touchscreen panel.

4.3 Configuring the Machine

In the first input screen of the welding

process proper (Display 5), the key data of

the last welding are shown (material, diame-

ter, and wall thickness of the welded pipe).

Furthermore, the status bar at the top of the

screen shows the date, time of day, and also

either the current ambient temperature or the

power supply voltage or the welder’s name or

code.

Display 4

Info

In Display 5, the welder has the possibility to:

• immediately start a welding process

that will be performed with the same

welding parameters as the previous

welding (touch the “Ok” button and

move on to section 4.6);

• enter new pipe-related data for the next

welding (touch the “New” button and

move on to section 4.4);

• change the machine settings in the con-

figuration menu (touch the “Menu” but-

ton);

• to read a new welder ID code using the

scanning wand; or

• display the date for the next scheduled

maintenance on the screen by touching

“New” button for some time.

Display 5

The first five options of the configuration menu are immediately accessible,

the other options will be displayed only after an access code for the ma-

chine, the so-called selection code, was entered (see Display 6). The menu

has the items listed in the following table. To toggle between various possi-

ble settings, or to open a sub-menu for a given menu item, touch the appro-

priate button.

Some of the buttons next to menu

option change their color when

they were pressed and are then

displayed as though the button is

held down. In this case the “held

down” button mean that this

menu option is the selected

ption.

tains the options

listed in the following table.

o

The Configuration Menu con

Version December 2006

agru SP 110-S User’s Manual

11

Display 6