PIPE SAW 380SP

21

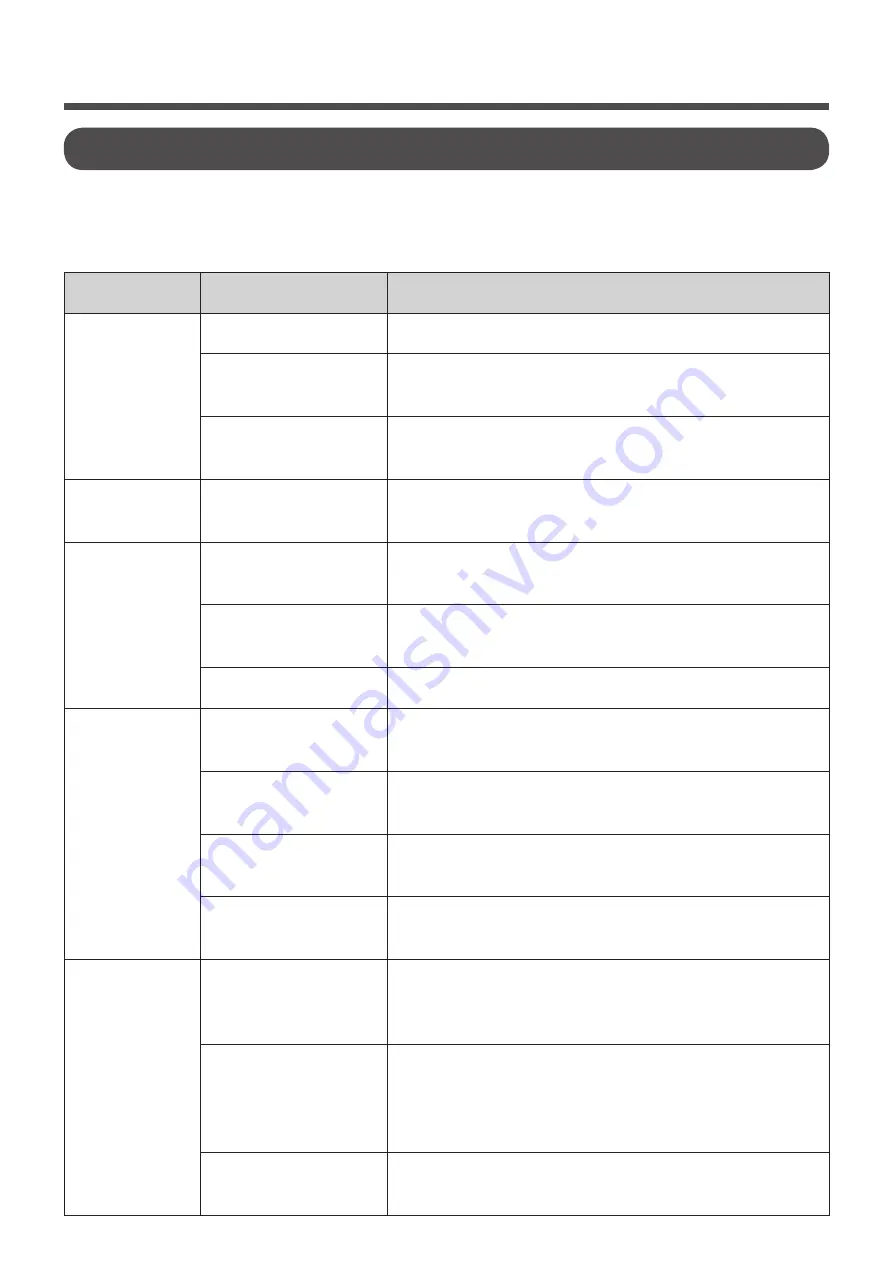

TROUBLESHOOTING

● Before asking for repairs, check following troubleshooting.

If the problem cannot be solved, contact with the shop you purchased or our sales office.

● Troubles due to misuse or improper applications are not covered by warranty.

Phenomenon

Cause

Measures

Power Issue /

Machine not

working

Damaged Power Cord

Replace the power cord if damages are found.

Low voltage

When the extension cord is too long or too thin, see

"Extension Cord" on P10 and use a proper extension cord.

Working Over-load

Protector

Make sure that the motor is cooled down enough, and

then turn on the switch again.

Insufficient

power

Low voltage

When the extension cord is too long or too thin, see

"Extension Cord" on P10 and use a proper extension cord.

The Saw Blade

is broken, and

/ or is loose

Loosed Clamp Bolt of

Blade Holder

Re-tighten Clamp Bolt.

Forcing the machine

to cut

Do not cut by force. Cut slower.

Unfixed Chain Vise

Fix the Chain Vise to the work piece firmly.

The machine

stops during

cutting

Low voltage

When the extension cord is too long or too thin, see

"Extension Cord" on P10 and use a proper extension cord.

Working Over-load

Protector

Make sure that the motor is cooled down enough, and then

turn on the switch again. Do not cut by force. Cut slower.

Worn out Carbon

Brushes

If Carbon Brushes are worn down to around 6㎜, they

must be changed.

Worn out saw blade

If the saw blade is worn out, cannot cut properly.

Change the saw blade to new one.

Oblique

cutting

Worn out saw blade

If the saw blade is worn out, it causes of oblique

cutting. Change the saw blade to new one when it's

worn out.

Jammed

contaminations

between Chain Vise

and the work piece

Remove the contamination jammed between Chain Vise

and the work piece.

Forcing the machine

to cut

Do not cut by force. Cut slower.

Содержание 380SP

Страница 23: ...PIPE SAW 380SP 22 ...