34

Periodic Maintenance

The user is responsible for establishing and respecting its maintenance schedule.

These following recommendations can be completed by the checklists given by the VDI 6022 (p. 35 - 36).

We recommend a first checking of the evaporative pad after 300-360 operating hours to confirm that the

bleed-off control is correctly done. Adjust it if necessary (see page 29) and check again after 300-360 operat-

ing hours more.

We recommend to service the EvaPack™ twice a year minimum. This frequency can be adapted according to

the operating conditions (water and air quality, application etc. ) and the official maintenance/applicable rules.

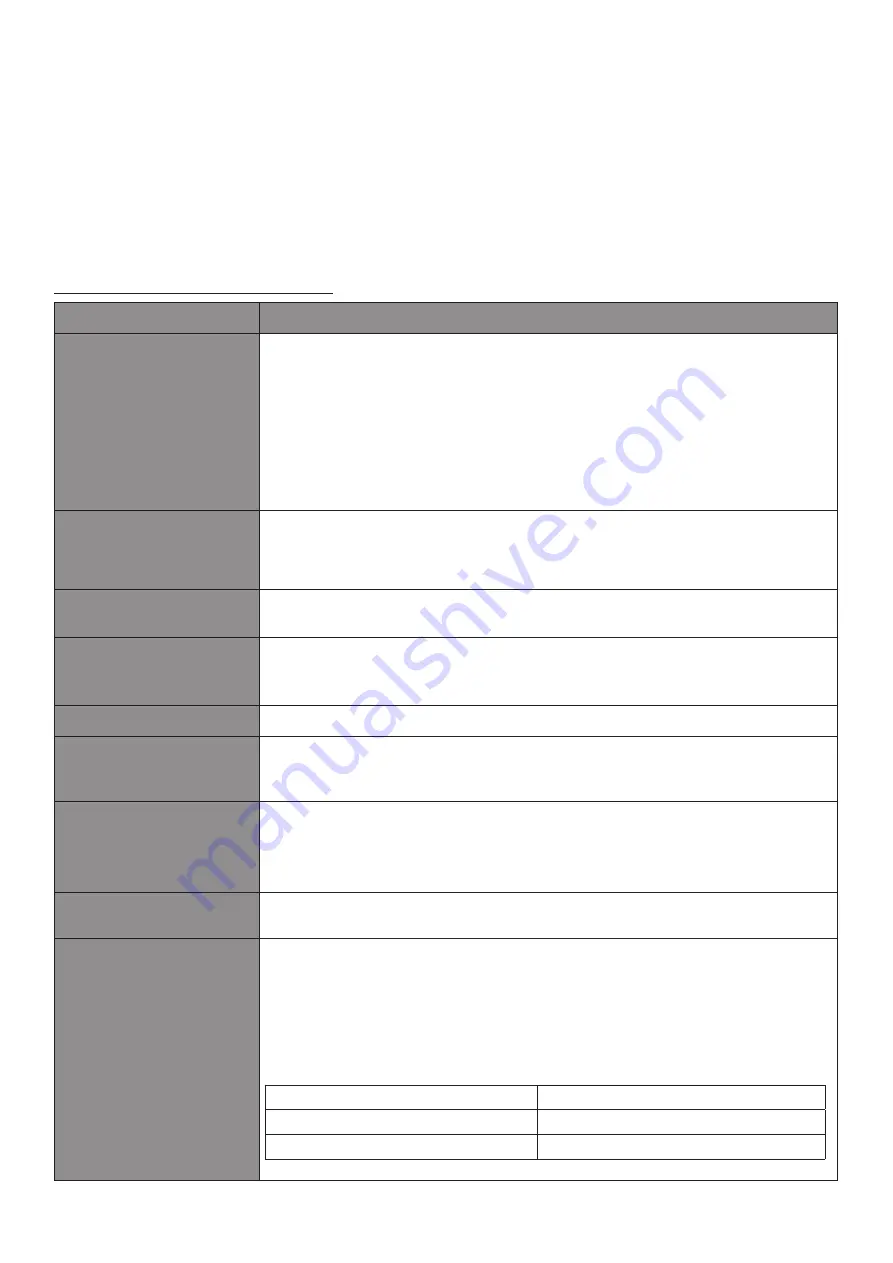

Recommended maintenance points

PARTS

MAINTENANCE

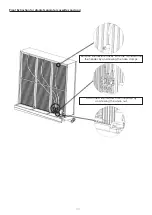

EVAPORATIVE PAD

Check the salt deposit, if the pad has a lot of salt deposit:

-Check the water quality

-Increase the bleed-off

Check the dust deposit, if there is a lot of dust deposit:

-Check the upstream filter condition

-Clean the evaporative pad with fresh water

If the dust/ salt deposit cannot be eliminated, the consequences can be:

efficiency decreasing, pressure drop increasing or microbiological contamina-

tion, etc., we recommend to change the evaporative pad.

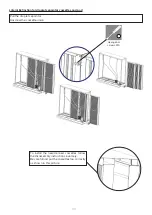

DROPLET SEPARATOR

Check the clean condition of the droplet separators, and if necessary:

-Check the upstream filter condition

-Dismantle the droplet separators cassettes to clean them with detergent and

disinfectant

FRAME STRUCTURE

Check the tightness of the frame, clean the structure and the water basin with

detergent and disinfectant. Check corrosion, clean and repair if necessary.

WATERING SYSTEM

(HEADER, VALVES,

FLEXIBLE HOSES, ETC.)

Check the tightness of the different elements.

Seal or replace leaking elements and clean them carefully with detergent and

disinfectant.

DRAINING ELEMENTS

Check and clean with detergent and disinfectant if necessary.

ELECTRICAL ELEMENTS

Check all components (solenoids, motors, connections, cables, etc.), replace

the defective components and fix the incorrectly connected elements.

Check sensors , clean or repair them and if necesary calibrate them.

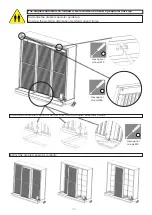

MANIFOLD

Check the manifold status, if the watering manifold orifices are clogged by

mineral salt deposit, it is possible to:

-Clean them by compressed air blowing or with a swab. It is possible to screw

off the brass plug.

WATER TREATMENT

ELEMENTS (OPTION)

Check the filters and change them if necessary.

MICROBIOLOGICAL

CONTROL

We recommend a frequent visual inspection and microbiological sampling of

the humidifier water.

An increase of CFUs values beyond the parameters given in the table below,

must be avoided.

If CFUs values are above these parameters, the unit must be cleaned and

disinfected properly.

Parameter

Recirculating water in air humidifiers

Total number of CFUs

< 1000 CFU/ml

Legionella spp.

< 100 CFU/100 ml

Содержание EvaPack Series

Страница 46: ...46 Notes...

Страница 47: ...47 Notes...