19

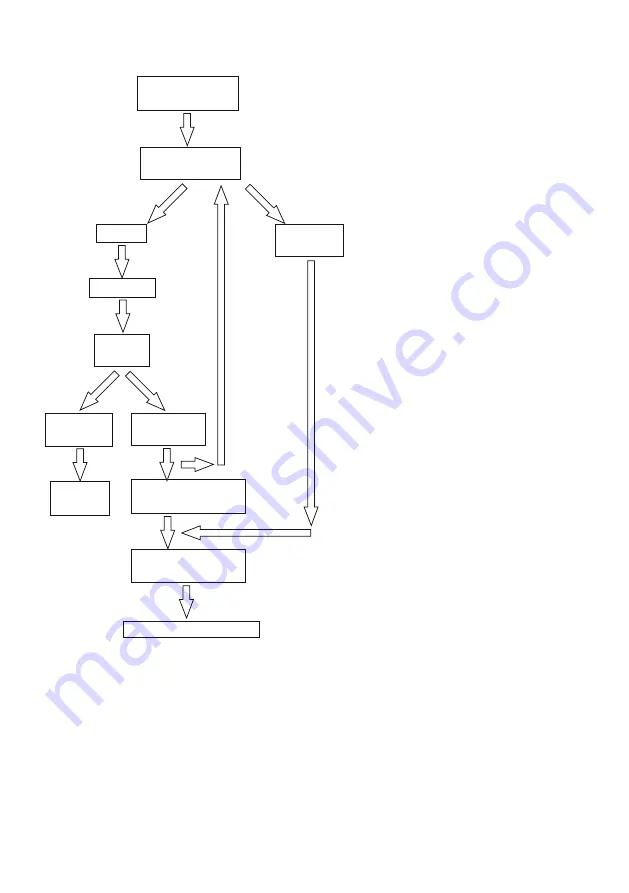

Fitting Field Test Audit (FC2)

go to commissioning FC1 (9.2)

2nd instance

follow maintenance

instructions (section 12)

1st instance

reset, follow

setting instructions

accept

& record

mixed temp.

same as at

commissioning

2.0 C

±

º

deviation from

previous >+2.0ºC

check mixed

temperature

restore cold

pass

fail

see 12

undertake the cold

water isolation test

see 9.5

water supplies same as

previous audit or

∆t change >5ºC

9.5

In-field ‘Cold Water

Isolation’(CWI) test.

Note: To gain access to the cold water

isolating

valve, unscrew the right hand shroud &

slide forward to expose the isolating

screw on top of the cold inlet leg.

Using a 5mm Allen Key, The isolation plug

can be screwed down fully to isolate the

cold water supply

Prior to commencing the CWI test, ensure:

1. The water supply conditions are met

either:

A. For commissioning a new product

(see table 1, section 4).

B. Or the inlet ∆t is within ±5°C to when the

product was commissioned (see 9.4).

NOTE It is important that the hot

temperature is greater than 55°C

2. Mixed water outlet temperature is

correct (see table 2, section 10).

To perform a CWI test, operate the product

using the sensor. Then conduct the follow-

ing procedure:

1. Record the steady state temperature of

both hot and cold water supplies.

Note the ∆t.

2. Record the temperature of the mixed

water at the outlet.

3. Isolate the cold water

supply & monitor the flow of water from

the outlet.

If the flow ceases, CWI test passed:

1. Restore the cold water supply by rotating the isolator screw 90° clockwise.

2. Slide the shroud back & screw onto the wall plate.

3. Re-check the temperature of the stabilised mixed water at the outlet to ensure it is still correct.

Accept & record mixed temperature.

If there is an ongoing flow of water from the mixed water outlet, then 5 seconds after CWI collect the

discharging water into a measuring vessel for 60 seconds. To pass the CWI test the volume of collected

water should be less than 120ml.

If the product fails CWI test, see FC2 (section 9.4). Follow product maintenance (see section 12) and

servicing (see section 10) instructions.