KARINA

English

Before starting the assembly process, unpack all components of the staircase. Lay them out on a large

surface and check the quantity of all the pieces, by consulting the table (TAB.1: A = Code, B = Quantity).

Inside the staircase box you will also find a DVD which we suggest watching before proceeding to assemble.

For customers in the USA there is a customer assistance number 1-888 STAIRKT, which you can telephone

in case of problems.

Assembly

Carefully measure the floor-to-floor height.

1.

Calculate the rise:

2.

1) subtract 22 cm (8

5/8

”) from the floor-to-floor height you measured,

2) divide this value by the rises number minus one.

Example: for the measured floor-to-floor height of 268 cm and a staircase with 12 rises;

(268 - 22) / (12 - 1) = 22,36

(8’3

1/2

” - 8

5/8

”) / (12 - 1) = 8

3/4

”.

Determine the position of the support N19 (fig. 1) keeping in mind two points:

3.

1) the rise, calculated previously, also contains the tread depth (L19 or L20) (fig. 2).

2) position the support N19 keeping in mind the opening feature (fig. 3).

Drill with the drill bit D. 14 mm (

4.

9/16

”).

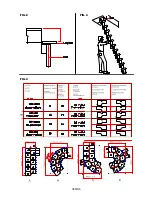

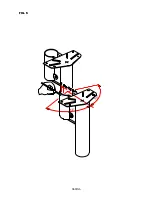

Assemble on the floor, in a straight line, the supports N19, N18, N17 and N16 keeping in mind

5.

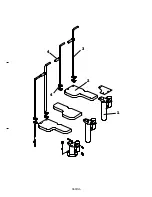

the calculated rise. Use the parts C15, B71 and B75 (fig. 1). Tighten sufficiently keeping in mind that the

supports N19, N18, N17 and N16 still have to rotate for the configurations B, C, D.

Lift and position the structure with the support N19 which has to touch the floor (fig. 4). If the stair

6.

place is too tight, it is suggested to rotate some supports.

Tighten the support N19 completely, by using the part C39 (fig. 1).

7.

Place on the floor, in sequence, one left tread (L19), one right tread (L20) and so on. Now determine

8.

which will be the first tread from the top (fig. 3).

Cut along the shape (fig. 7 - center page).

9.

Decide where to assemble the railing (inside or outside) (fig. 3) and pierce the treads (L19, L20) with the

10.

drill bit D. 6,5 mm (

1/4

")

using the template only for the straight sides

. To find the fixing point

on the short side of the winding treads (L19, L20) maintain the same distance as the one between the

balusters (C12) to assemble on the long side of the tread (fig. 3).

Assemble and tighten the parts F23 by using the parts C14, B83, B86, C13, B02 (fig. 1).

11.

Fasten element N26 to the treads L19 and L20 using the screw C40.

12.

Finally attach the treads (L19, L20) starting from the bottom N16 up to the support N19, using the

13.

elements C40 (fig.1).

1.The configuration A (straight) doesn’t need any further changes (fig. 3).

14.

2. The configurations B or C need a rotation of 13° (fig. 3).

3. The configuration D needs a rotation of 18° (fig. 3).

To rotate the supports of 13° or 18° you have to proceed as follows:

15.

a. Set out with a pencil, at the connection point of two supports, two vertical lines at a distance

of 9 mm (

23/64

”) (to rotate 13°, configuration B or C) (fig. 5) or 13 mm (

33/64

”) (to rotate 18°, configuration D)

(fig. 6).

b. Loosen the parts C15, one support by one, starting from the top and rotate until one of the lines

matches the one of the top according to the direction of rotation.

c. Tighten the parts C15 completely (fig. 1).

Assembly of the Railing

Assemble the parts C28 by using the parts C13, B02 and insert them into the balusters (C12) (fig. 1).

16.

Insert the balusters (C12) into the parts F23, blocking them by the part B02.

17.

The first balusters (C12) of the long side of every tread (L19, L20) have to be cut.

18.

Tighten the part C28 completely, by using the part B02 (fig. 1). For a correct assembly twist the key at

19.

about 90° from the contact point.

Содержание KARINA

Страница 1: ...English ASSEMBLY INSTRUCTION Español INSTRUCCIONES PARA EL ENSAMBLAJE KARINA ...

Страница 2: ...KARINA ...

Страница 8: ...KARINA ...

Страница 9: ...KARINA FIG 1 ...

Страница 10: ...KARINA FIG 7 ...

Страница 11: ......

Страница 12: ...KARINA FIG 2 FIG 4 FIG 3 ...

Страница 13: ...KARINA FIG 5 ...

Страница 14: ...KARINA FIG 6 ...

Страница 15: ...KARINA ...

Страница 16: ...English PRODUCT DETAILS Español DATOS DE IDENTIFICACIÓN ...

Страница 17: ...KARINA 1 2 3 4 4 ...