001.10610.EN rev

. 13

Care and Maintenance

16

Care and Maintenance

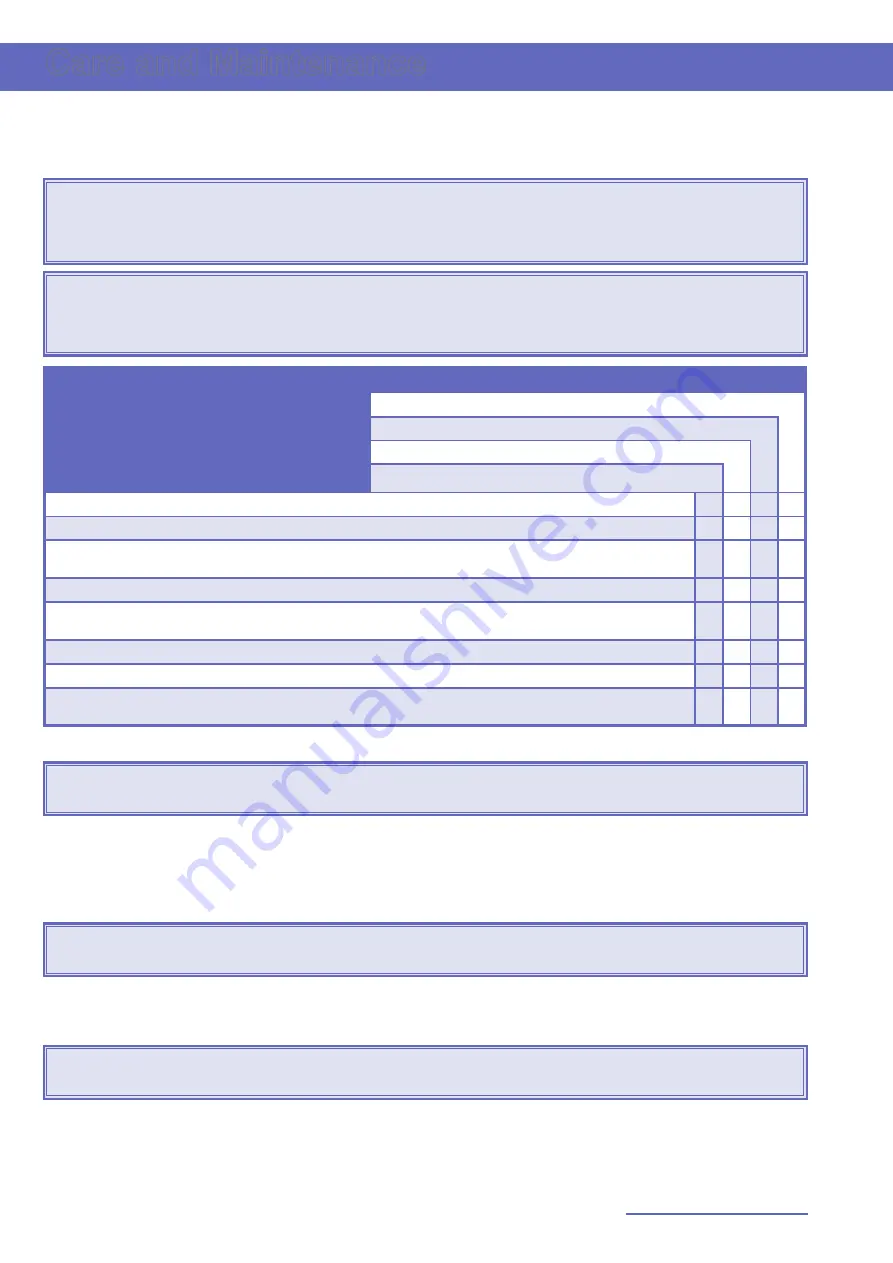

Preventive Maintenance Schedule

The

EASYTRACK

is subject to wear and tear, and the following actions must be performed when specified

to ensure that the product remains within its original manufacturing specification.

WARNING

: The points on this checklist are the minimum the manufacturer recommends. In some

cases more frequent inspections should be carried out. Continuing to use the

EASYTRACK

without

conducting regular inspections will seriously compromise the user and resident / patient’s safety.

Preventive maintenance specified in this manual can prevent accidents.

WARNING:

Safety related maintenance and authorized service must be carried out by qualified

personnel, fully trained in servicing procedures by Arjo and equipped with correct tools and proper

documentation, including

Parts List

and

Service Manua

l. Failure to meet these requirements could

result in personal injuries and / or unsafe equipment.

POINTS TO BE INSPECTED BY

USER / SERVICE TECHNICIAN

FREQUENCY

Annually / every 1400 transfer / every 50 assembling*

Monthly

Before every use

Before installing

Inspect for evidence of external damage or missing parts.

Ensure all components are in working order.

Using the clip-on level, make sure that all posts are straight. If any post is not straight remove the

track and level post accordingly.

Red mark on top of each post (under the top plate) is not visible.

The tracks are secured in place. Press down on each track to make sure they are locked onto the

posts.

Clean the inside of the tracks to ensure there is no dust or grease build-up inside the tracks.

Check to make sure that the trolleys move freely along the tracks.

Make sure the padding on the foot and top plate is clear of any foreign substance and is not

damaged. Have the paddings replaced accordingly.

* Which ever comes first: Annually - every 1400 patient transfer cycles - every 50 assembling/disassembling cycles.

WARNING

: If any of the above inspection point fails, DO NOT USE the

EASYTRACK

system until

appropriate corrective action is taken.

Annual Inspection by an Authorized Technician

The

EASYTRACK

must be inspected by a qualified Arjo technician on an annual basis to ensure

the proper functioning of its components, as well as the safety of the patients and care givers that

use the

EASYTRACK

. Please contact your local representative to make arrangements.

NOTE

: If the product does not work as intended, immediately contact your local Arjo agent for

support.

Cleaning

To clean the

EASYTRACK

, wipe it down with a damp cloth using warm water and mild detergent.

CAUTION

: Do not use phenol, chlorine or any other type of solvent that may damage the

finish.

To ensure a better rolling surface for the trolley wheels, clean the inside of the track every four

months. To do so, insert a damp cloth in the opening and slide it from one end of the track to the

other.