Subject to change_RPERX3-06_14095_1en_03/2022

Page 15

www.argo-hytos.com

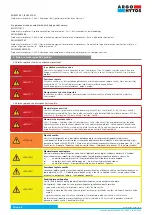

WARNING

Correct installation of the valve

The four sealing rings on the base of the body must be undamaged and inserted into the recesses, the

connection surface of the plate sufficiently machined and undamaged, the valve must be fixed with four

fastening bolts tightened to the specified torque. Failure to meet these conditions for proper valve installation

may result in leakage of working fluid.

The solenoid windings heat up during operation. Effective external cooling must be provided to ensure that the maximum winding temperature is not

exceeded, by not exceeding the maximum fluid and ambient temperature and by maintaining minimum volume of the connection block. A valve

body volume of (152.5 cm

3

) is sufficient for one manifold. If several valves that can be switched simultaneously are connected on the connection

plate, a distance of at least 10 mm must be maintained between the bodies of adjacent valves (see fig).

T

P

B

A

T

P

B

A

T

P

B

A

85 (3.35)

55 (2.17)

110 (4.33)

60 (2.36)

WARNING

Switching solenoids

Directional control valves with two solenoids, coils must not be switched at the same time.

There is a risk of damaging the valves.

WARNING

Coil cooling

Coil cooling takes into account the cooling surface of the hydraulic part of the valve.

Do not power separately disassembled coils. Excessive winding heat, insulation damage and short circuiting

between coils may occur. For the same reason, the surface of the coils must not be covered, exposed to direct

heat sources or sunlight. The valve must not be closed in a tight space without ensuring air circulation.

7.3 Commissioning

Before commissioning the hydraulic ciruit, check that the valve is correctly mounted on the connection plate and that electrical supply cables are

correctly connected. The valve is not to be adjusted. Test operation should be conducted without the pressence of an explosive atmosphere. After the

hydraulic circuit has been commissioned, check the valve for leaks. Simply verify the directional control valve function, repositioning the spool by alter-

nately switching the solenoids and monitoring the movement of the appliance or the amount of pressure in the appliance branches (ports A and B).

7.4 Normal operation

During normal operation , the directional control valve spool is adjusted by the solenoids. Normal operation of the system does not require any

manipulation of the valve.

DO NOT exceed the MAXIMUM PARAMETERS

, shown in table 4.4.

OBSERVE THE OPERATIONAL RESTRICTIONS AND AVOID THE RISKS

, referred to in paragraph 3.

USE PROTECTIVE EQUIPMENT

When working with hydraulic fluid, it is recommended to wear safety goggles, protective rubber gloves and sturdy shoes with non-slip soles.

Содержание RPERX3-06

Страница 2: ...Subject to change_RPERX3 06_14095_1en_03 2022 Page 2 www argo hytos com ...

Страница 3: ...Subject to change_RPERX3 06_14095_1en_03 2022 Page 3 www argo hytos com ...

Страница 4: ...Subject to change_RPERX3 06_14095_1en_03 2022 Page 4 www argo hytos com ...

Страница 21: ...Návod k použití_RPERX3 06_14095_1cz_03 2022 Strana 2 www argo hytos com ...

Страница 22: ...Návod k použití_RPERX3 06_14095_1cz_03 2022 Strana 3 www argo hytos com ...

Страница 23: ...Návod k použití_RPERX3 06_14095_1cz_03 2022 Strana 4 www argo hytos com ...