31-DVIM33

20

Control access

behind trim

Care must be taken when accessing the controls while fireplace is active. Parts will be

HOT

SURROUND INSTALLATION

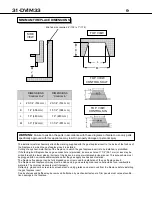

Surround options available are dependent upon the con-

trol panel configuration. (See Control Panel Locations

regarding configuration.) Shallow surround options are

not available on a unit with ‘Controls Out’ configuration.

Make sure the gas and electrical lines are properly con-

nected to the appliance. Slide the unit into the fireplace

and slide the excess flue liner material back onto the

chimney. Before the appliance is fully recessed into the

fireplace, attach the surround onto the appliance.

Attach the surround to the appliance at the locations

shown by lining up the tabs on the surround with the

slots on the unit. Make sure the surround drops down

and fully engages. Then finish with the wiring connection

to the on/off switch on the side of the trim. Now fully

“seat” the unit into its final position.

Surround Mounting slots

Surround Mounting

tabs

Restrictor installed

in upper baffle.

Center air channel

is closed off with

restrictor

Firebox baffle w/out

restrictor.

All three air channels

in the baffle are open

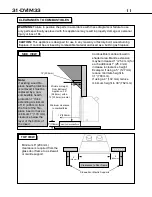

VENT RESTRICTOR INSTALLATION

When the vent is over 18’(5.5m) a vent restrictor may be required. The installation of the restrictor will equalize the vent

stack action that can cause problems with a proper fire set-up.

The vent restrictor is supplied loose in the manual bag. When required, it installs onto the upper baffle in the center portion.

The baffle air openings are located in the top of the firebox just inside the front frame of the fireplace. There are holes al-

ready in the standoffs that will line up with the holes in the restrictor.

Upper Baffle

air channels

Upper Baffle

Содержание 31-DVIM33

Страница 39: ...31 DVIM33 39 NOTES ...

Страница 42: ......

Страница 43: ...Archgard Industries Ltd 7116 Beatty Drive Mission B C V2V 6B4 Canada Website www archgard com ...