LUBRICATED PLUG VALVES - SAPM/SAPL

Australian Pipeline Valve - Installation, Operation and Maintenance Manual

18

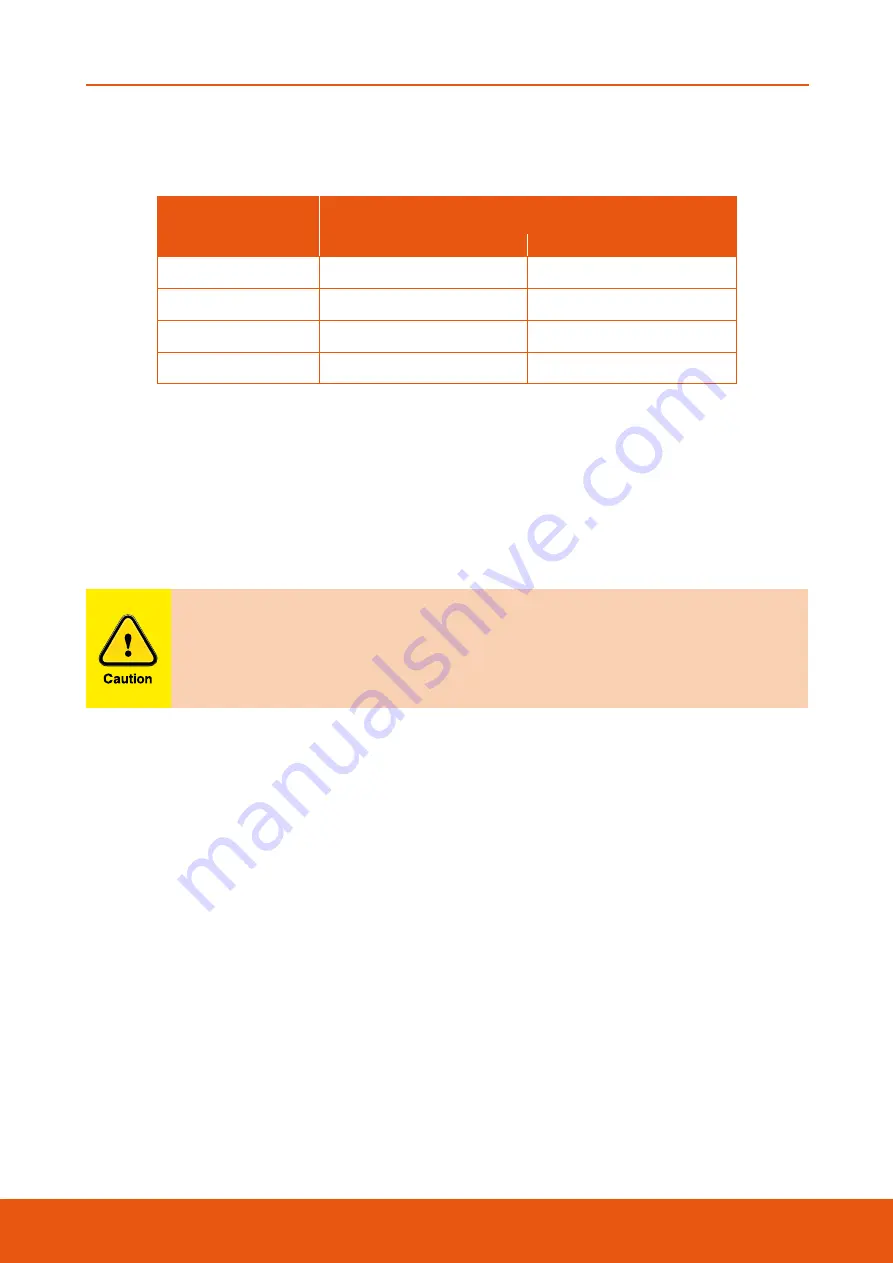

TABLE 3

Frequency of lubrication using operation frequency as a guide

FREQUENCY OF VALVE

USE

FREQUENCY OF SEALANT INJECTION FOR A VALVE IN

STANDARD SERVICE

NO MORE THAN

NO LESS THAN

10-100 times a day

Daily

Weekly

1-10 times a day

Weekly

Monthly

1-30 times a month

Monthly

Quarterly

Several times a year

Quarterly

Biannually

The choice of lubricant should be in accordance with the process medium and the service temperature

range (see lubrication Table 2 & 3 above).

It is recommended that the valve be periodically stroked (at least partially) to ensure valve functions, and

will aid to prevent seizure/galvanisation on any mating surfaces (or in the case of resilient seats).

Duration depends on service, criticality, etc.

There are different types of lubricants available depending on temperature and service. Special lubricants

for worn or corroded valves are available as well as flushing agents to remove old grease.

Use extreme caution when injecting sealant into a valve in the closed position with

a non compacting fluid in the valve.

B) CONFIRM SUSPECTED STEM LEAKAGE

The following methods can indicate stem leakage.

a) Gas services - applying a detergent solution around the stem area will produce soap bubbles if

the stem is leaking. A bad leak may be heard as a hissing noise from the stem area.

b) Liquid services - stem leak on a liquid service will be visible as liquid flowing out from

where the stem protrudes from the body.

c) Gear operated valves - the area where the stem protrudes from the body is hidden by the gear

operator. Confirm stem leak by observing or applying a detergent solution around relief valve

(where fitted) in the gear operator indicator plate, and the gear operator to the valve body

mounting area.

d) Portable electronic hydrocarbon detectors - some are sensitive enough to detect stem leaks by

placing the probe adjacent to the stem.

If a hexagon socket/headed screw bottoms out inside the stem packing, and the stem is still leaking, then

more stem packing compound needs to be loaded into the stem packing. This is done by removing the hex

socket/headed screw and putting a new piece of stem packing compound into the injector unit and

energising it with the hexagon socket/headed screw.