CHECK/ADJUST

NOZZLE

CO

‐

PLANARITY

WITH

BOARD

LEVEL

Turn

on

machine

and

open

software

The

following

procedure

is

for

making

sure

that

the

reflow

nozzle

edges

are

parallel

or

co

‐

planar

to

pcba

or

board

level

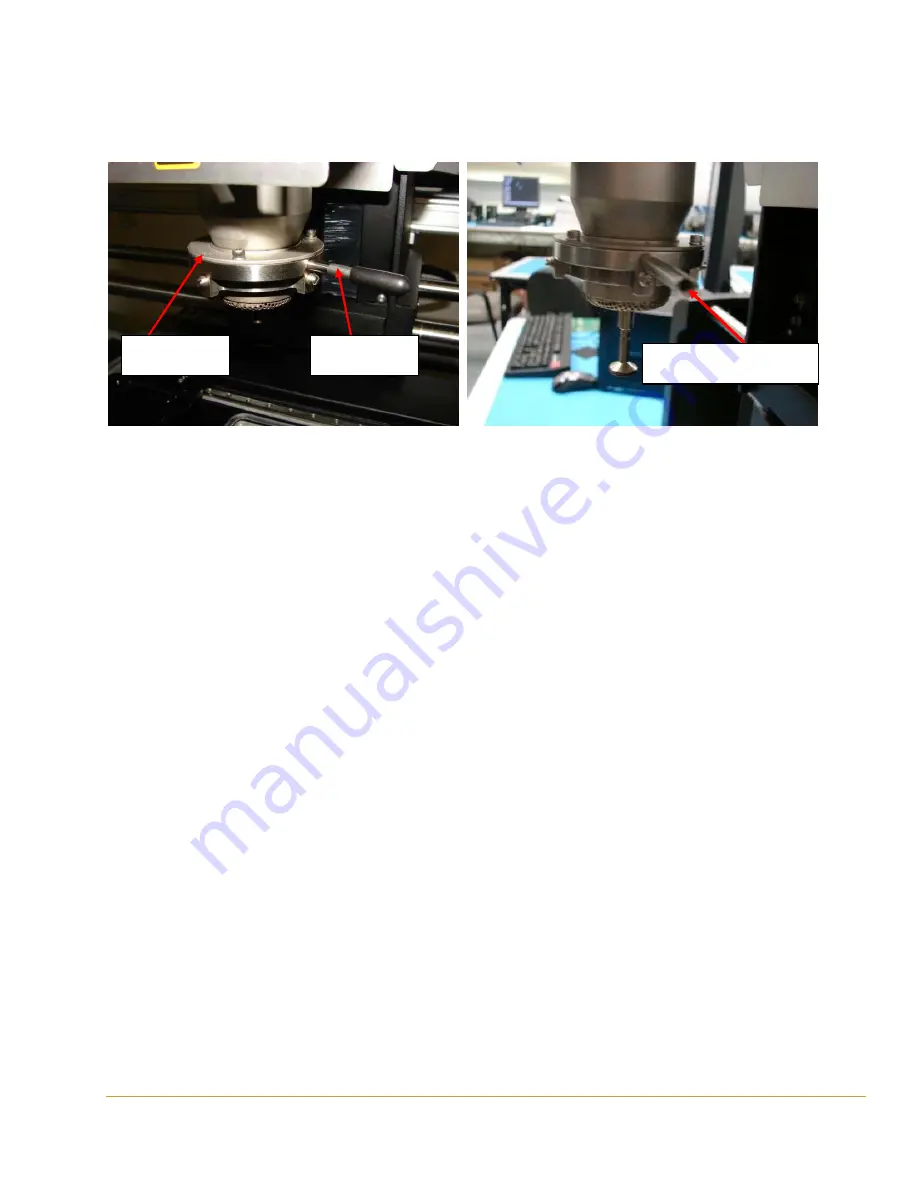

23. Attach

a

reflow

nozzle

to

the

APR

nozzle

ring.

The

preferred

nozzle

size

is

a

large

size,

NZA

‐

400

‐

400

or

NZA

‐

450

‐

450

for

example.

24. If

available,

install

an

unpopulated

pcba

into

the

board

holder.

If

necessary,

reverse

mount

the

bottom

plate

of

the

optical

kit

so

bottom

faces

up.

All

that

is

needed

is

a

flat

surface

at

pcba

level

to

compare

with

nozzle

edge.

25. Verify

that

the

board

is

level

in

board

holder

26. Remove

any

VNZ

pipette

from

the

vacuum

tube,

it

will

not

be

necessary

for

this

procedure.

27. Bring

the

head

downward

in

FAST

speed

until

head

stops.

Switch

to

COARSE

speed

and

bring

down

reflow

nozzle

edge

to

about

0.25”

(10.0mm)

above

board

level.

Switch

to

FINE

speed

and

adjust

to

5

‐

10

mil

or

as

needed.

Bring

the

head

down

until

the

reflow

nozzle

edges

are

just

above

board

level.

28. Examine

all

4

sides

of

the

reflow

nozzle

edges

with

respect

to

board

level.

All

4

sides

should

be

parallel

to

board

level.

29.

If

nozzle

edges

are

not

parallel

or

co

‐

planar,

adjust

the

3

spring

‐

loaded

screws

holding

the

heater

head

assembly

to

the

head

casting.

For

side

‐

to

‐

side

(pivot)

adjustment

concentrate

on

2

rear

screws.

For

front

‐

to

‐

rear

(pivot)

adjustment

concentrate

on

front

screw.

Final

adjustment

may

require

a

combination

of

the

3

adjust

screws.

NOTE:

Ensure

that

3

screws

for

holding

heater

head

assembly

are

not

too

loose

so

the

heater

head

is

hanging

loosely

off

the

head

casting.

If

screws

get

too

loose,

tighten

up

all

3

screws

to

get

a

new

starting

point

and

start

co

‐

planarity

adjustment

over.

Nozzle lever

Nozzle ring

Adjust set screw inside to

tighten nozzle ring