Installation and Service Manual – Under-the-Counter Point of Use 5 Stage Reverse Osmosis System with Booster Pump

Copyright © 2014 Applied Membranes, Inc.

All Rights Reserved.

Page 16

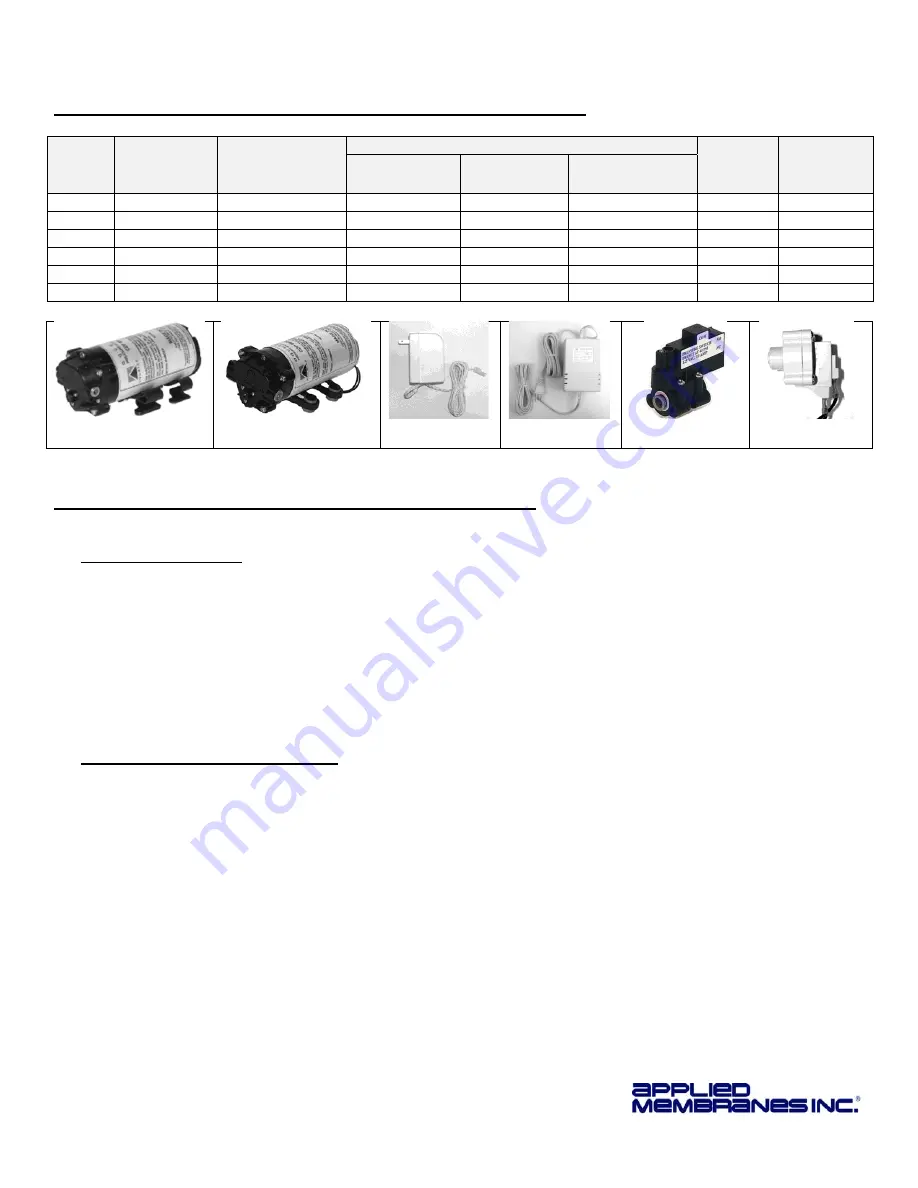

Replacement Pump & Pump Components

System

Flow

Rate

System

Model

Number

Replacement

Pump Model

Replacement Power Supply

Tank

Shut-Off

(TSO)

Low

Pressure

Switch

USA

(U)

Japan

(J)

European

(E)

12 GPD AAA-125P*

6840-2J03-B221 TAS114-19EP TAS104-19 TAS234-19EP PSW240 LPS340G

24 GPD AAA-245P*

6840-2J03-B221 TAS114-19EP TAS104-19 TAS234-19EP PSW240 LPS340G

36 GPD AAA-365P*

6840-2J03-B221 TAS114-19EP TAS104-19 TAS234-19EP PSW240 LPS340G

50 GPD AAA-505P*

8851-2J03-B423 TACS114-48 TACS104-48 TACS234-48RF PSW240 LPS340G

75 GPD AAA-755P*

8851-2J03-B423 TACS114-48 TACS104-48 TACS234-48RF PSW240 LPS340G

100

GPD

AAA-1005P* 8851-2J03-B423 TACS114-48 TACS104-48 TACS234-48RF PSW240 LPS340G

6840-2J03-B221

(6800 Series Low Flow Pump)

8851-2J03-B423

(8800 Series High Flow Pump)

TAS114-19EP

(6800 Power Supply)

TACS114-48

(8800 Power Supply)

PSW240

(Tank Shut Off Switch)

LPS340G

(Low Pressure Switch)

Pump Troubleshooting Information

1) The pump will not run:

a) Start at the source to determine where the electrical current flow has been interrupted. Use a multi-meter to check

the line voltage, and the transformer output. If the transformer is not functioning properly its current capacity may

have been exceeded. Replacement may be necessary.

b) If the transformer is properly sized, and is delivering the correct voltage to the system, remove the holding tank

pressure switch (PSW) from the system by disengaging both connectors, and connecting the pump directly to the

transformer.

i) If the pump now runs, the pressure switch is faulty, and needs adjusted or replaced.

ii) If the pump still fails to run, the electrical path has been interrupted within the motor, and should be replaced.

2)

The flow and/or pressure is too low:

Most Aquatec boost pumps are designed to limit the maximum output pressure to 110 psi, to protect the membrane

and other components from damage. The normal operating pressure as measured after the pump, and before the

membrane, will be approximately 80 psi. The flow rate of the 6800 series pump during operation is about 500 ml/min.

The 8800 is double that flow. If these parameters are not being met, please check the following:

a) Is the pump properly sized to handle the production rate of the membrane, plus the brine flow allowed by the

restrictor (usually 4 or 5 times the permeate production)?

b) Is the system receiving adequate feed water? The pump’s inlet chamber must be flooded to prevent performance

robbing air ingestion into the compression chambers.

c) Debris entering the pump may restrict the pumping operation. Consult the factory for valve cleaning instructions.