7

The above specifications were current at the time this manual was published, but because of

our policy of continuous improvement, APEX Machine Group, reserves the right to change

specifications at any time without prior notice.

UNPACKING

Open shipping container and check for shipping damage. Report any damage immediately to

your distributor and shipping agent. Do not discard any shipping material until the collector is

installed and running properly. Compare the contents of your container with the following parts

list to make sure all parts are intact. Missing parts, if any, should be reported to your distributor.

Read this instruction manual thoroughly for assembly, maintenance and other instructions.

Be sure to check inside the filter, by opening the door to find manual and sample of additive for

water.

INSTALLATION AND ASSEMBLY OF UNIT

ELECTRICAL INSTALLATION:

All electrical work must be done by a qualified electrician or qualified person according to local,

state and national codes.

Caution:

Installation can cause exposure to live components. Be sure to disconnect electrical

power before proceeding with installation.

Determine the location where the collector will be installed. Be sure to allow sufficient room

around the unit to service the sludge collection bin, or roll the unit out of position. Allow for the

inlet ducting and the exhaust air also. When selecting a location consider the floor surface;

a smooth and level floor will be helpful when moving unit for cleaning.

1. Uncrate collector using caution not to damage the paint while lifting or dismantling the

crate.

2. Remove any other item that may be on the skid.

3. When using a forklift, be careful lifting the unit as it is top heavy.

4. After placing the unit onto its location be sure to lock the front caster so the unit does not

move.

5. When make the electrical connection, a quick power plug is recommended so it is easy to

disconnect when unit is required to be moved for cleaning.

6. Check blower for proper rotation direction; if blower rotation is backward, interchange two

of the motor lead connections. (L1 and L2)

7. Start unit by depressing the start button located on the starter box.

8. Check total current draw on the motor with water in the unit and at the proper level. If the

amperage is higher than the rating on the motor, either the water level or the inlet needs

to be blocked off to reduce the total amperage. (For best performance, the motor should

run a few amps lower than total listed on motor name plate).

9. Water is added as needed through the front-loading door. Water should be filled to a level

about ½ way up the water sight window. (Middle of sight glass or approx. 9” up). Note

Содержание PWDC-5

Страница 1: ...1 Operations Manual Model PWDC 5 Wet Collector ...

Страница 9: ...9 ...

Страница 10: ...10 ...

Страница 11: ...11 ...

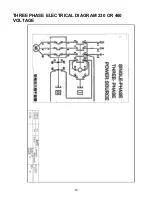

Страница 13: ...13 THREE PHASE ELECTRICAL DIAGRAM 230 OR 460 VOLTAGE ...

Страница 16: ...16 ...

Страница 18: ...18 ...

Страница 19: ...19 ...

Страница 20: ...20 ...

Страница 21: ...21 ...

Страница 22: ...22 ...