6

6

6

6

SPECIFICATION

Voltage Input :

available in 110V / 220V

Station Dimensions:

110(w) x98 (h) x 155 (d) mm

Weight:

1.5Kg

Power Consumption:

70W

Temperature Range:

200°C - 480°C

Heating Element

Ceramic heater

Output voltage:

24V

CONTROL PANEL GUIDE

FUNCTIONS and FEATURES

•

Microprocessor-controlled ESD safe Soldering station.

•

Composite tip design.

•

Compatible with Lead free applications.

•

High power heating element for fast heat recovery.

•

Large display with digital controls.

•

Auto sleep and wake up function.

•

Digital offset.

•

Programmable sleep timer.

•

System-lock out feature.

•

Quick jump to favorite settings.

•

Switch between Centigrade and Fahrenheit scale.

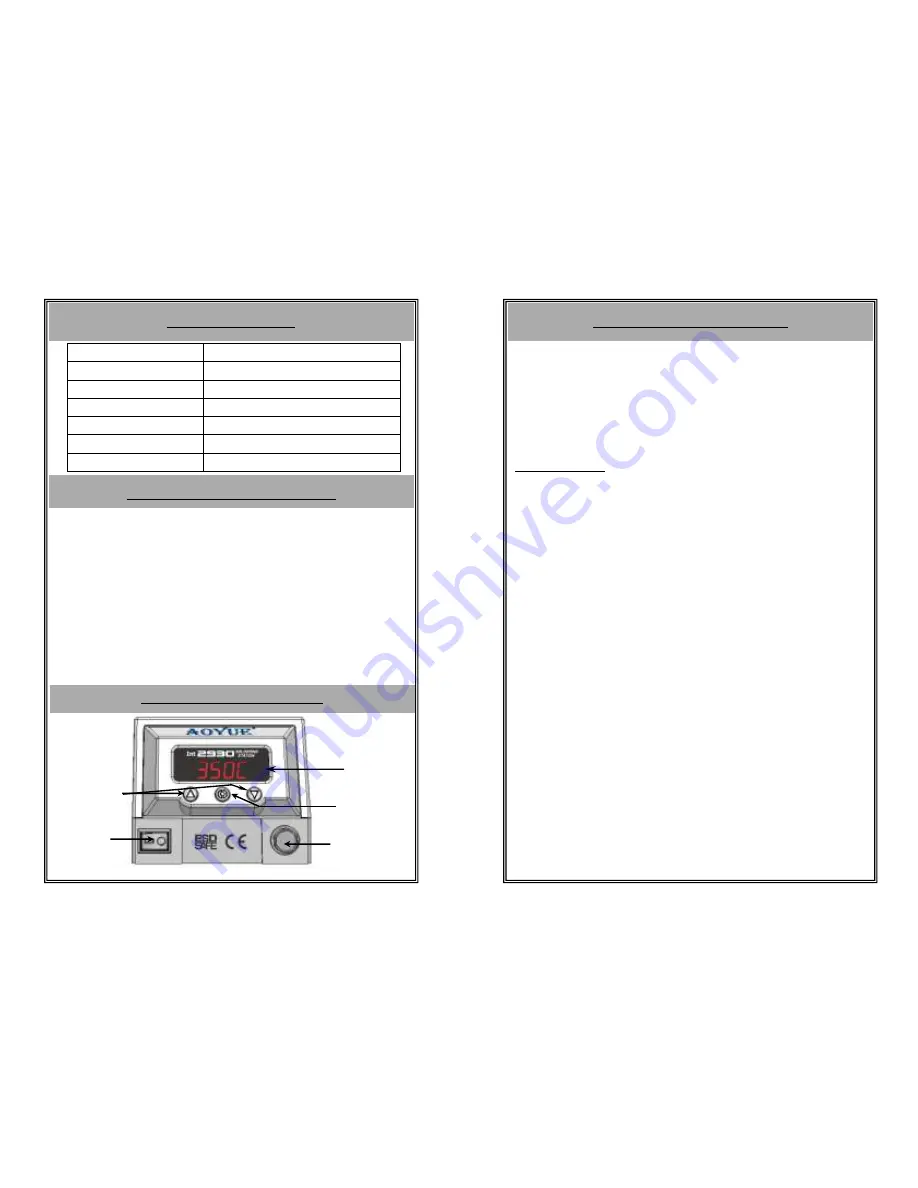

2

1

Main

Display

Increase/

decrease buttons

3

Main power

switch

5

Solder iron

connector

4

Set Button

11

11

11

11

OPERATING GUIDELINES

3. “t000” indicates that the sleep function is currently turned off. To

adjust the timer settings press the increase or decrease button.

Sleep timer is adjustable from 2 to 60 minutes.

4. To save the settings, repeatedly press the SET button until the

display shows the word “SAVE”. Press the decrease button to save

and exit from the system configuration mode.

F. SYSTEM LOCK

The System lock feature disables adjustment to both temperature

and system configuration. The display will show “ SAFE” when system

lock feature is enabled. To disengage system lock press and hold all

three buttons for more than ten seconds.

To activate the system lock feature:

1. With the unit turned On, press and hold the SET button.

2. Wait for the display to change to “A###”, then repeatedly press the

“SET” button until “L0FF” is displayed. This denotes that we are

now configuring the system lock setting.

3. “L0FF” indicates that the system lock function is currently disabled.

To engage the system lock press the decrease button to switch the

lock feature to “LOn”.

4. To save and activate the system lock settings, repeatedly press the

SET button until the display shows the word “SAVE”. Press the

idecrease button to save and exit from the system configuration

mode.

5. The display would show the word “ SAFE”, indicating system lock is

enabled.

When the system lock feature is enabled changing of temperature

and system settings are blocked. The system lock must be disengaged

to re-enable access to the system.