13

Adjustment

After a period time, wear in some of the moving components

may need to be adjusted.

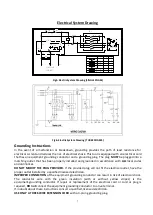

Compound Rest Adjustment

Loosen the two screws (A. Fig. 20), after you have obtained the

angle you want, do not forget to tighten them again.

Fig. 20

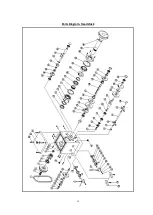

Belt Adjustment

Loosen the two nuts and screws (A. Fig. 21) to remove the plate

of mounting motor and position.

Fig. 21

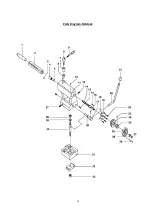

Main Spindle Bearing Adjustment

The main spindle bearings are adjusted at the factory. If end play

becomes evident after considerable use, the bearings may be

adjusted. Loosen two hex socket cap screws (A, Fig. 22) in the

slotted nut on the back of spindle. Tighten slotted nut until all end

play is taken up. The spindle should still revolve freely.

Tighten two hex socket cap screws.

Caution: excessive tightening or preloading will damage the bearings

Fig. 22

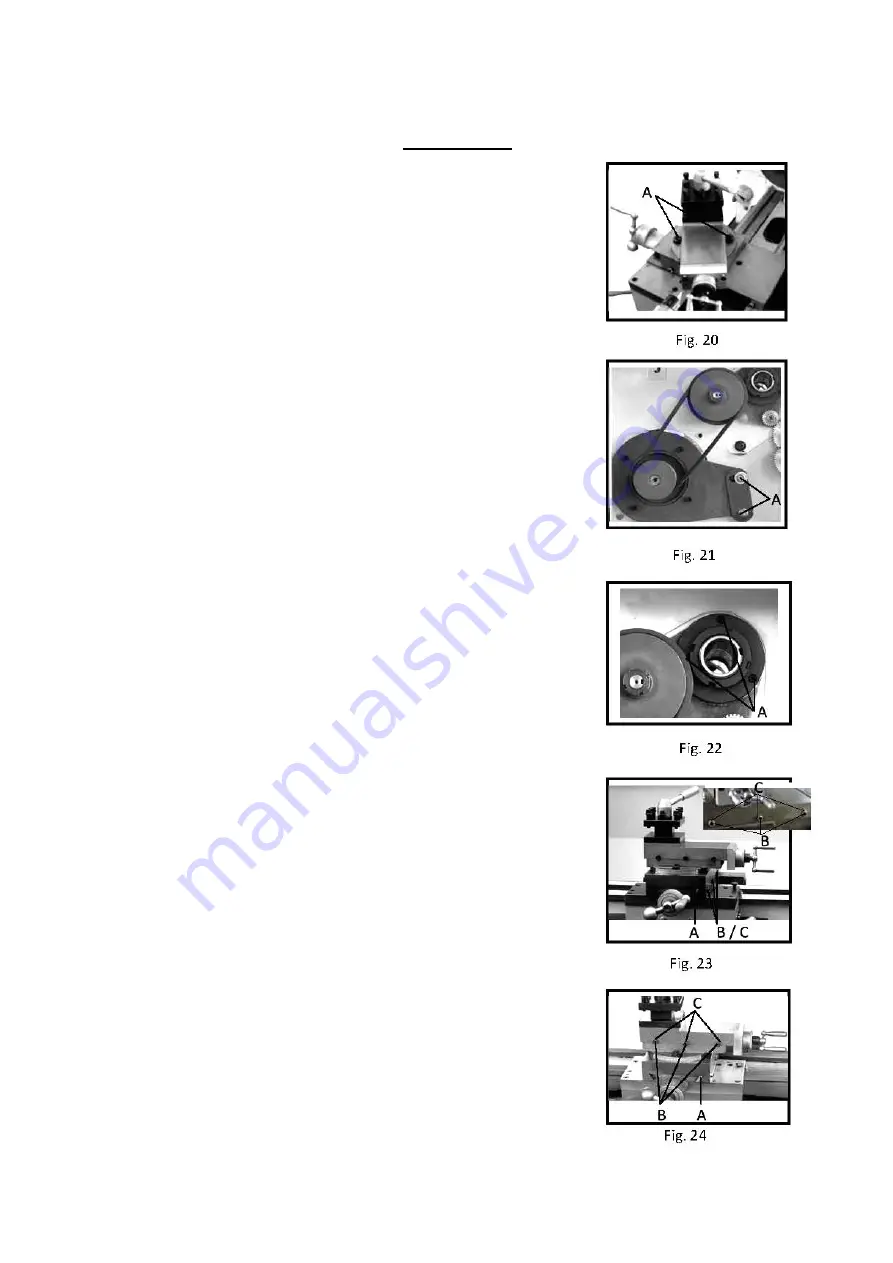

Cross Slide Adjustment

The cross slide is fitted with a gib strip (A, Fig. 23) and can be adjusted

with screw (B, Fig. 23) fitted with lock nuts (C, Fig. 23). Loosen the

lock nuts and tighten the set screws until slide moves freely without

play. Tighten lock nuts to retain adjustment.

Fig. 23

Top Slide Adjustment

The top slide is fitted with a gib strip (A, Fig. 24) and can be adjusted

with screw (B, Fig. 24) fitted with lock nuts (C, Fig. 24). Loosen the

lock nuts and tighten the set screws until slide moves freely without

play. Tighten lock nuts to retain adjustment.

Содержание BL330E

Страница 1: ......

Страница 10: ...10 ...

Страница 14: ...14 Parts Diagram Headstock ...

Страница 16: ...16 Parts Diagram Trestle ...

Страница 18: ...18 Parts Diagram Bed ...

Страница 20: ...20 Parts Diagram Apron ...

Страница 22: ...22 Parts Diagram Tailstock ...

Страница 24: ...24 Parts Diagram Change Gear Box ...