Controls

Basic controls and connections

Control by building managemant system

Boiler enable signal

Temperature or capacity setpoint

18

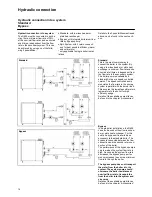

Basic controls and connections

The standard version of the R600 is

equipped with a KM628-R600 boiler

management unit. This controller

controls both the burner safety operati-

on and the temperature regulation of

the boiler. The KM628-R600 includes

the following functions:

When additional control of secundary

heating zones or cascade systems are

required, the R600 can be extended

with different additional controls. Expla-

nation of these controls can be found in

the next sections.

•

Electronic high limit thermostat

•

Electronic flue gas temperature limiter

•

Primary boiler pump control (via re-

lay)

•

Primary sanitary hot water pump

control (via relay)

•

Interlock input

•

Lockout input

•

OK/Alarm output signal

•

Boiler enable signal

•

0-10VDC temperature or capacity

setpoint (programmable)

•

0-10VDC capacity feedback or 10V

contact for external gas valve

(programmable)

•

Temperature control central heating

via PID controller

•

Temperature control sanitary hot wa-

ter (hot water priority)

Control by building managemant

system

The R600 can be connected to a buil-

ding management system. This can be

done by using (one of) the following

connections:

0

20

40

60

80

100

0

2

4

6

8

10

[V]

[ºC]

0

20

40

60

80

100

0

2

4

6

8

10

[V]

[%]

Boiler enable signal, terminals 22-23

(230V)

The boiler enable signal is provided

with a jumper from the factory. When

connecting a (volt free!!!) external sig-

nal, the jumper must be removed.

Temperature or capacity setpoint,

terminals 117-118 (0-10VDC)

The R600 can be controlled via a

temperature or capacity setpoint. The

following graphs show the signal va-

lues for both possibilities.

Temperature setpoint

A signal below 2V will not be recogni-

sed by the boiler controller. In case of

a signal below 2V, the controller will

control the boiler temperature based

on the internal setpoint programmed

at parameter P1.

Capacity setpoint

The burner will be started when a

signal of minimum 3V is recognised.

The burner will be switched off, when

the signal drops below 2.9V.

When controlling the boiler via a ca-

pacity setpoint, it’s highly recommen-

ded to control the primary boiler pump

with the internal pump control of the

KM628 boiler controller. The mini-

mum flow rate through the boiler must

be respected at all times. The nomi-

nal

∆

T is 20K and should be at least

within 15K-25K at full load to secure a

safe boiler operation.

Содержание SH60

Страница 3: ...3 ...

Страница 7: ...Technical description Declaration of conformity 7 ...

Страница 26: ...26 UPS32 60F UPS32 120F UPS50 120F UPS65 120F Accessories Plug play kits ...

Страница 45: ......

Страница 46: ......

Страница 47: ......