Functions and setup of the contrAA 600

contrAA 600

Edition 01/2014

29

5.3.2

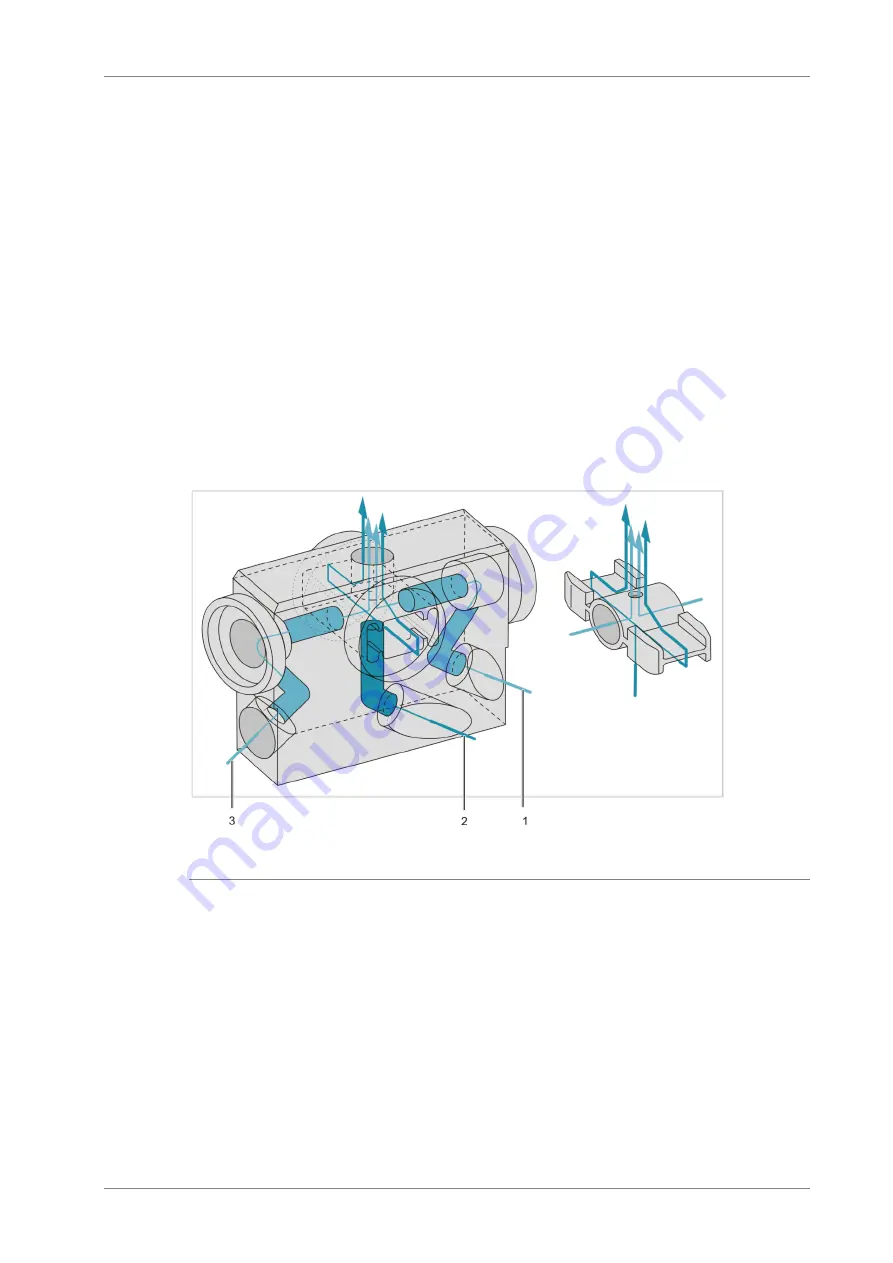

Gas flows in the graphite tube furnace

The furnace jacket houses the gas channels for the separate supply of the inner gas flow

(purge gas) and the outer gas flow (protective gas). Oxidizing or reducing gases (O

2

or H

2

)

can be added to the inner gas flow if necessary. They can have a positive effect on the

pyrolysis step.

Attention

:

When using air, temperatures > 600 °C should be avoided since the graphite tube itself will

then be attacked.

The inner gas flow has the task of removing all gases which occur in the graphite tube during

the drying and pyrolysis step, as well as of preventing condensation effects of the analyte on

the furnace windows and of influencing the residence time of the analyte atoms in the path of

the beam. During atomization, the inner gas flow is generally interrupted in order to achieve

the longest possible residence time for the atoms in the path of the beam of the graphite

tube and to increase the sensitivity of the measurement.

The outer gas flow sweeps the graphite tube and is also directed outside through the funnel

insert in the dosing opening. The outer gas flow is responsible for ensuring that the graphite

tube is surrounded by inert gas, even when the inner gas flow has stopped, and thus pro-

vides protection against oxidation by atmospheric oxygen.

1, 3 Inner gas flow (purge gas)

2

Outer gas flow (protective gas)

Fig. 10

Inner and outer gas flows in the graphite tube furnace

The heat flows inside the furnace jacket via a cylindrical attachment to the fixed furnace part.

This increases the operating temperature of the atomizer at its internal walls in a way that

condensation effects of the analytes (samples) are avoided.

The cone attachment on the opposite side of the furnace jacket forms together with the

insulating ring an exactly defined gap in the rotatable part of the furnace, ensuring that the

cell interior is sealed against ingress of ambient air. In the event of a tube rupture in the

furnace jacket, the insulating ring in the movable furnace part prevents a short circuit be-

tween the furnace parts.

The furnace jacket is drilled through in the direction of the optical axis, the outer cylinders

support the furnace windows (quartz cell windows). For cleaning, the windows can be easily

pulled off with a twisting motion.