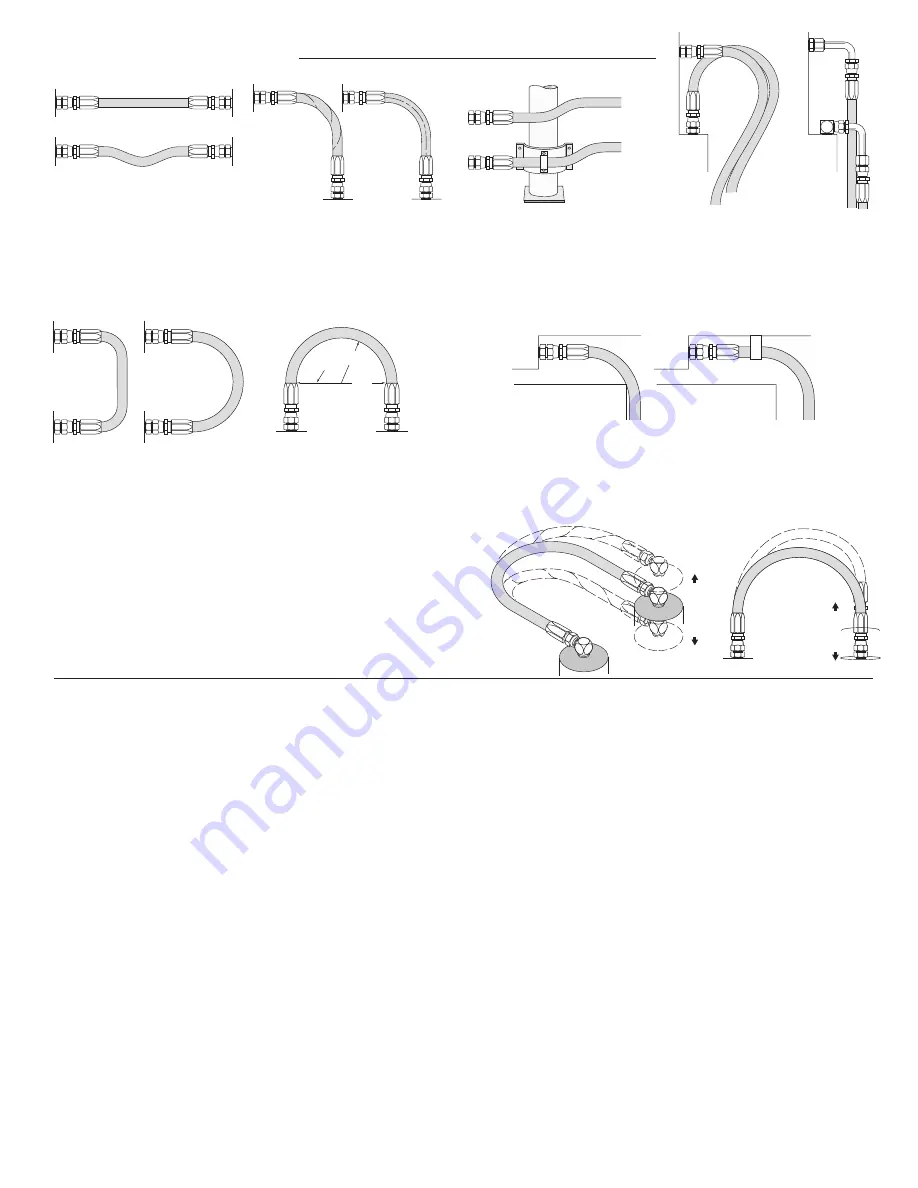

1. Provide for length change

In straight hose installations allow enough

slack in the hose line to provide for changes

in length that will occur when pressure is

applied. This change in length can be from

+2% to -4%.

RIGHT

WRONG

WRONG

RIGHT

7. Secure for protection

Install hose runs to avoid rubbing or abrasion. Use clamps to support long runs of hose or to

keep hose away from moving parts. It is important that the clamps do not allow the hose to

move. This movement will cause abrasion and premature hose failure.

RIGHT

WRONG

8. Avoid Improper Hose Movement

Make sure relative motion of the machine com-

ponents produces bending rather than twisting

of the hose. Hose should be routed so that the flex

is in the same plane as the equipment movement.

RIGHT

WRONG

5. Use proper bend radius

Keep the bend radius of the hose as large as

possible to avoid collapsing of the hose and

restriction of flow. Follow catalog specs on min-

imum bend radii.

RIGHT

WRONG

6. Use proper bend radius (cont.)

Maximum bend radius is measured on the

inside bend of the hose. To determine minimum

bend, divide the total distance between ends

(B length) by 2. For example 8 = 6, minimum

bend radius = 3.

3.00

RADIUS

6.00

DIAMETER

B

2. Avoid twisting and orient properly

Do not twist hose during installation. This can be

determined by the printed layline on the hose.

Pressure applied to a twisted hose can cause

hose failure or loosening of connections.

RIGHT

WRONG

3. Protect from hazardous environment

Keep hose away from hot parts. High ambient

temperature will shorten hose life. If you can not

route it away from the heat source, insulate it.

WRONG

RIGHT

Diagram H

Hose routing examples

AMSOIL INC.,

AMSOIL Bldg., Superior, WI (715) 392-7101

BP-258 9/09

To order By-Pass Oil Filter Parts or oil sample kits, consult your AMSOIL Dealer or the AMSOIL Product Price List for your country.

4. Avoid mechanical strain

Use elbows and adapters in the installation to

relieve strain on the assembly, and to provide

easier and neater installations that are accessible

for inspection and maintenance.

AMSOIL Oil Filter Change Recommendations

Vehicles with Gasoline or Diesel Fueled Engines

•

EaO and Donaldson Endurance ELF 7349

(Dodge Cummins 5.9L): Up to 25,000 miles (15,000 miles for severe service) or one-year

service life, whichever comes first, when used in conjunction with AMSOIL Synthetic oil. Always change oil filter at time of oil change.

•

EaBP By-pass Filters:

Should be changed every other full flow filter change up to 60,000 miles, whichever comes first. When used

with other brands of motor oil or full flow filters, the EaBP should be changed every other full flow filter change. AMSOIL recommends

using oil analysis when extending oil drain intervals.

•

Donaldson Endurance:

Heavy-duty commercial vehicles and off road equipment, when used in conjunction with AMSOIL Synthetic oil,

up to two times longer than OEM* recommendations, not to exceed 60,000 miles for on-highway diesel applications. Always change

oil filter at the time of oil change.

•

WIX and Donaldson”P” Series:

OEM* Recommendations.

•

MANN Filters:

Guaranteed up to 7,500 miles when used in conjunction with AMSOIL Synthetic Motor Oil.

Stationary Engines

•

EaO and Donaldson Endurance:

Up to two times longer than OEM* recommendations. Always change oil filter at time of oil change.

•

WIX and Donaldson”P” Series:

OEM* Recommendations.

BP258_95064 9/24/09 11:03 AM Page 6