SECTION E - GENERAL OPERATION AND DESIGN

E-1.

General

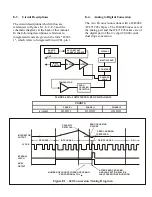

The AMPTEC RESEARCH 620A-4 Igniter

Tester is shown in block diagram form in Figure

E-1. All diagrams and information disclosed in

this chapter is proprietary and is included in

order to make troubleshooting to component level

possible.

The AMPTEC 620A-4 series Igniter Tester

uses modern solid-state semiconductors

exclusively and digital CMOS circuits

extensively to minimize power requirements

and make battery operation useful and

practical. AMPTEC also maintains a spare

parts inventory of all components found in the

620A-4 Tester and its customer service

department can also provide additional

assistance in the trouble shooting process.

E-2.

Troubleshooting

Since the 620A-4 Tester is used to test potential

deadly explosive force detonators and warheads

of missiles etc.,

personnel that are not qualified

to make such electrical repairs on the 620A-4

Tester should not even attempt to remove the

calibration access screws or open the main

panel or effect any repair whatsoever

.

Apparent 620A-4 Tester malfunctions can

sometimes be the result of bad test

lead/connection wiring, wrong connections,

misinterpretation of specifications, low battery

levels, and in rare cases due to an incomplete

understanding of the instrument and how to use it.

A thorough review of the operating instructions

for this instrument is recommended prior to any

component replacement. Check to be sure that

cables and other test equipment are in good

working order before attempting to troubleshoot

the 620A-4 series igniter tester.

If you turn on

the AMPTEC 620A-4,

and the

display does not come on

, it may indicate the

batteries need charging, or fuse needs replacing.

If the 620A-4 exhibits problems that cannot be

eliminated by reviewing Chapters B and D, the

following guidelines have been established to

help solve the problem.

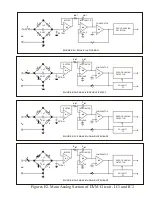

E-2-1. Localizing the Problem

Chapter D-2 discusses how to use the

Functional Test Section

of the 620A-4 Tester to

help localize the problem. The key to successful

troubleshooting is to localize the problem to a

general electronic parameter as much as possible

before trying to pin the problem down to a

specific component. Certain questions should

be asked such as "Does the problem occur on all

ranges or on a specific range only?". If the

620A-4 Tester does not come on when powered

up, did you check the front panel fuse. The

power supplies for both the current source and

the digital voltmeter electronics are also one of

the first things that should be tested.

As it is not possible to anticipate all failure

modes of the 620A-4 series igniter tester,

servicing personnel should become familiar with

this section to gain a complete understanding of

the internal workings of the ohmmeter.

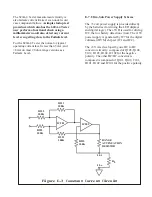

E-2-2. Component Replacement

If the malfunction is a faulty component, the

accuracy of the 620A-4 series igniter tester can

be maintained only if the 620A-4 is re-

calibrated following the component replacement

and the following precautions are taken:

Use only the specified component or its exact

equivalent. Spare parts can be ordered from

your nearest AMPTEC RESEARCH Service

Center or directly from the factory by referring

to the AMPTEC Stock Number listed in the

Parts Lists section at the back of this manual.

The highest quality 63/37 grade rosin core

electronic grade solder with a 50W or lower

maximum power soldering iron should be used.

Never use an acid core solder as corrosion of

components leads and PCB etch loss can occur.