Operation

Disassembly

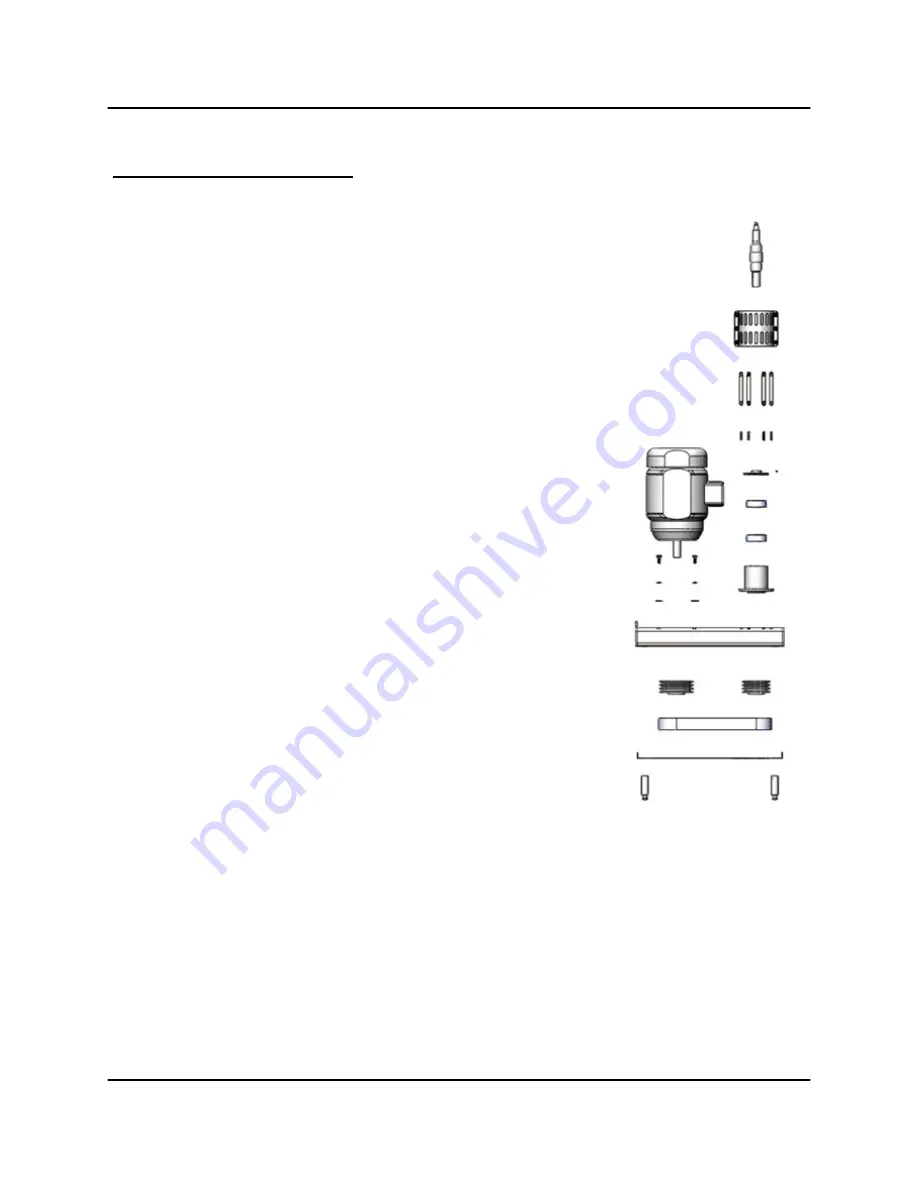

Models AC+3218 and AC+4329

Models AC+3218 and AC+4329 are operated by a pulley system

located on the underside of the base. To remove drive components

the entire blender and base must be tipped on its side. The motor

end should be toward the floor. The hopper, valve, inlet tubing,

casing, impeller, seal guard, and seal components should all be

removed before tipping the unit on its side.

1. On the top of the base, loosen the mounting bolts that secure the

drive to the base. The base is slotted so the motor may be slid

toward the blender.

2. Remove the drive belts.

3. Remove the bolts that secure the blender pulley to the underside

of the base.

4. Use those same bolts and tighten into the forcing holes. Finger

tighten.

5. Using the appropriate wrench, tighten the bolt until the pulley

releases from the bushing. Remove the bolt and the pulley.

6. Remove the tapered bushing from the shaft of the blender.

7. To remove the adapter ring and spacers, hold the adapter ring

to prevent it from falling while you remove the six cap screws.

8. Set the blender back down on all four legs.

9. Loosen the bearing housing from the base by removing the cap

screws .

10. Grasp the bearing housing with both hands and firmly lift it off the

blender base.

11. Remove the retaining ring.

12. Press the shaft from the housing. Use the appropriate puller to

remove the bearings from the shaft then remove the second

bearing from the housing.

13. Check the stub shaft for nicks or scratches.

14. All components should be checked for cracks or wear. Check

o-rings for damage. Inspect the legs for worn threads. Worn or

damaged components should be replaced.

Bearings are sealed and have lifetime lubrication. Worn or damaged

bearings should be replaced with identical bearings and be replaced as

a set.

Ampco Pumps Company

Page 9

Ampco Pumps Company AC+ Dry Blender Manual M-028 Rev C 12.20