©Copyright Amkus Rescue Systems, Inc. 2010-2020

LAP-005 JUNE 22, 2020 Rev05

Routine Maintenance for Gasoline Engine

Follow the maintenance guidelines in the engine owner’s

manual.

Routine Maintenance for Hydraulic Pump

Normally, you will have a maintenance agreement for

your system with your local dealer. However, if you have

decided to service the equipment yourself, please review

the following instructions carefully.

Change hydraulic fluid after each 20 hours of tool operation

(approximately every 2 years). If you suspect your

hydraulic fluid has been contaminated in any way, contact

your local dealer or AMKUS, Inc.

To change the hydraulic fluid, remove the hydraulic fluid

reservoir fill plug/vent cap. Place the unit over a drain pan;

unscrew and remove the drain plug. Be careful not to lose

it! Allow the hydraulic fluid to drain. Clean and replace

the drain plug. Fill the hydraulic fluid reservoir with new

AMKUS mineral base hydraulic fluid. Replace the fill plug/

vent cap.

Connect the male and female couplings on each of the

hydraulic hose line sets, creating a loop. Follow the

operating instructions in the engine owner’s manual for

starting the engine. Then operate the engine at full speed.

To purge air from the hydraulic hoses, charge each hose

line by moving the knob on the corresponding selector

valve to the pressure position (in line with the selected hose

line) and allow the fluid to circulate through each hose line

for at least one minute. Move each selector valve back to

the neutral position. Check the level of the hydraulic fluid

in the sight gauge. Add more fluid if necessary. DO NOT

OVERFILL.

Uncouple the male and female couplings on each hydraulic

hose line set to open the loop that was created earlier.

Check the pressure output of the power unit at each hose

line by connecting a pressure gauge to the pressure line

(the male coupling). Move the selector valve to charge

the line to which the gauge is connected. The nominal

pressure of the system is 10,500 psi. The pressure reading

you receive should be between 10,000 psi and 11,000

psi. If you have a reading outside of that range, contact

your local dealer or AMKUS, Inc. DO NOT ATTEMPT TO

ADJUST THE PRESSURE RELIEF SETTING!

Routine Maintenance for Hoses

After each use, hoses should be wiped clean with a light

cleaning solvent such as Simple Green

®

. Inspect hoses

for damage to the rubber outer cover. Damage which

exposes the wire braided reinforcement subjects the wire

to corrosion and may weaken the hose. Damaged hoses

should be replaced.

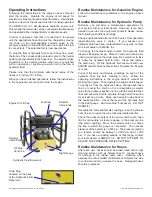

Drain Plug

(located on the back

of the Hydraulic Fluid

Reservoir)

Fill Plug

Vent Cap

Fuel Cap

Selector

Valve Knob

Selector

Valve Knob

Hydraulic Fluid Reservoir

Sight Gauge

Engine Oil Fill Cap

Operating Instructions

Following the instructions in the engine owner’s manual,

start the engine. Operate the engine at full speed for

maximum rescue tool speed and performance. Use the idle

position only when the rescue tools are not being operated.

The GB2S-XLO is a simultaneous operation power unit.

This means that two tools can be connected simultaneously

and operated either independently or simultaneously.

In order to operate a tool that is connected to the power

unit, the appropriate hose line must be charged by moving

the knob on the corresponding selector valve to the

pressure position (in line with the hose line to which the tool

is connected). The selected tool is now operational.

To stop the flow of hydraulic fluid to each hose line, move

the knob of the corresponding selector valve to the neutral

position (perpendicular to the hose line). The selector valve

should be in the neutral position when you are finished

with an operation or anytime you wish to stop the flow of

hydraulic fluid.

Please note that the minimum safe bend radius of the

hoses is 4 inches (101.6 mm).

When you have finished operations, follow the instructions

in the engine owner’s manual to stop the engine.