14

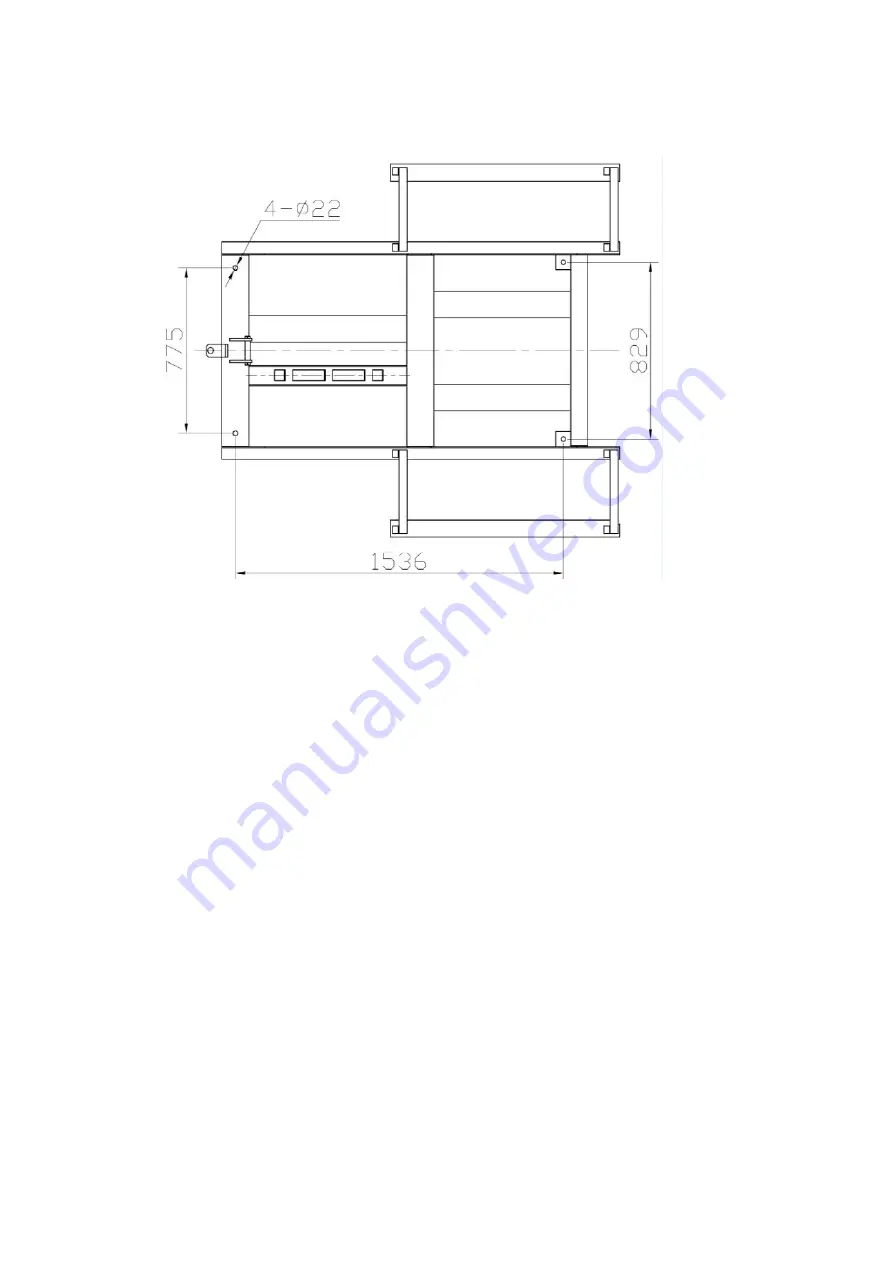

1. There are four fixed holes in the machine, can fix the machine on ground by

3/4 X 5 1/2” anchor bolts

(See Fig.19)

.

VI. MAINTENANCE SCHEDULE

Monthly:

1. Lubricate all moving parts with lubricant.

2. Check all connectors, bolts and pins to insure proper mounting.

3. Make a visual inspection of all hydraulic hoses/lines for possible wear or leakage.

Every six months:

1. 1. Make a visual inspection of all moving parts for possible wear, interference or

damage.

2. Check all fastener and re-torque.

Oil cylinder maintenance:

In order to extend the service life of the oil cylinder, please operate according to the

following requirements.

1. Recommend to use N46 anti-wear hydraulic oil.

2. The hydraulic oil of the lifts should be replaced regularly during using. Replace the

hydraulic oil 3 months after the first installation, Replace the hydraulic oil once a

year afterwards.

Fig.19