3

WARNING

!

Depressurize valve before servicing.

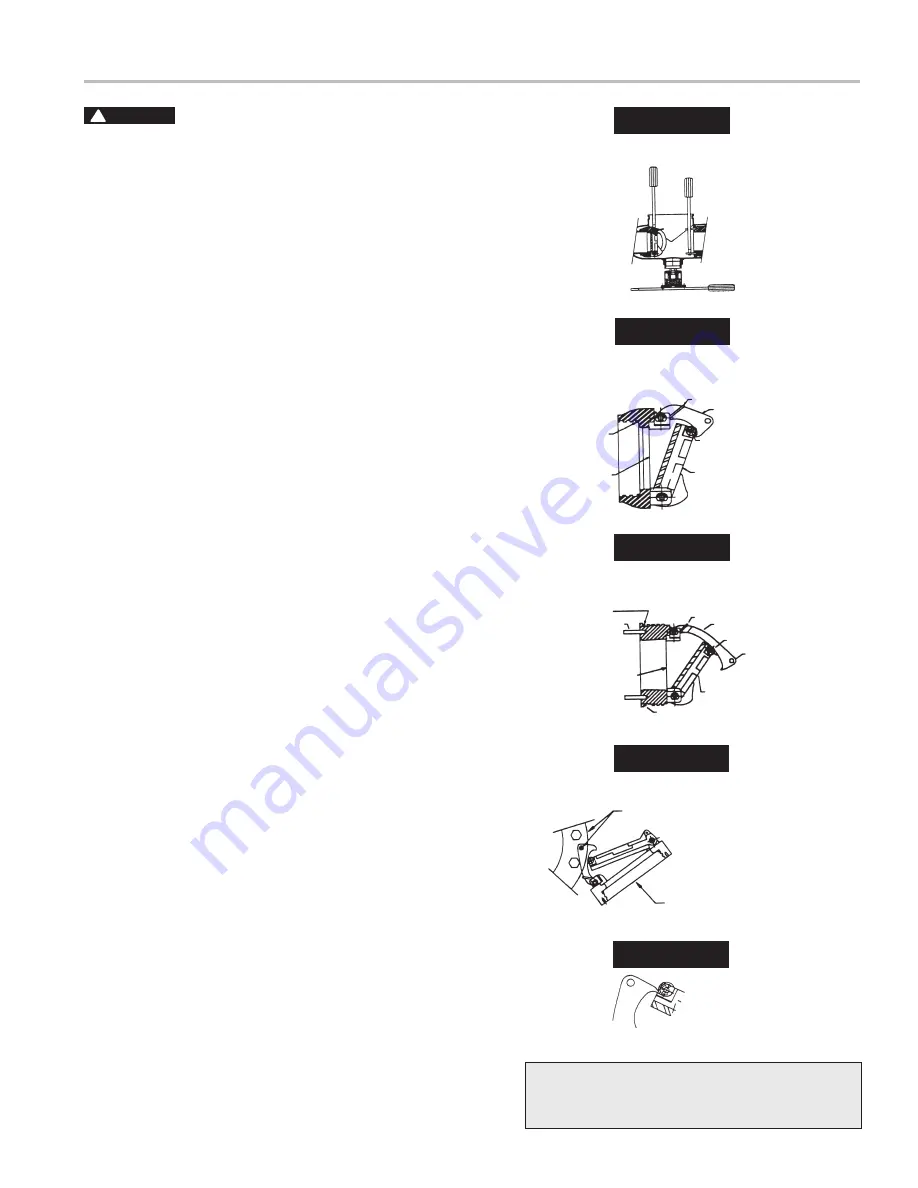

Removing Cam-Checks

1. Shut down water system and lock out system if possible. Slowly

open all ball valves to relieve air and water pressure. Loosen

bolts on groove coupler and remove groove coupler and cover

plate from valve body.

2. Remove #1 Cam-Check Assembly by using your hands to

unscrew (turn counterclockwise) Cam-Check and remove

through top access port.

Do not use Cam Arm as a handle

to unscrew Cam-Check.

If Cam-Check cannot be loosened

by hand, insert a long screwdriver between valve body and

Cam-Check (see Figure 3). Gently apply pressure against the

Cam-Check until loosened. Finish unscrewing by hand. Un-

screw #2 Cam-Check (turn counterclockwise) by placing a long

screwdriver across lugs and applying pressure to loosen #2

Cam-Check. Finish unscrewing by hand.

3. To clean #1 Cam-Check (except 2

1

/

2

" – 4" (65-100mm) DC

Check), locate the Cam Arm opening stud on the outlet flange

of the valve assembly. Slide the Cam Arm over the stud with the

check threads facing downward (Figure 5A). Tighten

1

/

4

" nut on

stud to secure cam bar. Slowly pull the assembly outward to

open check. The clapper so that the end of the Cam Arm rests

between roller and clapper (Figure 5B).

Thoroughly clean the seat area and clapper sealing surfaces of

both Cam-Checks. Rinse Cam-Checks and O-rings thoroughly.

Inspect seats, clapper sealing surfaces, Cam Arms, and O-rings

for damage, nicks, and debris. If damaged, install a new Cam-

Check assembly and/or O-ring or shutoff disc.

4. Before reinstallation of check assembly, thoroughly clean

O-ring groove and lubricate with F.D.A. approved lubricant.

Insert and thread #2 Cam-Check first and then #1 Cam-Check.

#2 Cam-Check should be tightened by inserting a long screw-

driver between lugs to tighten firmly (see Figure 2). Do not over

tighten. Tighten #1 Cam-Check firmly by hand only. Replace

cover plate, clean groove coupler gasket and groove. Replace

groove coupler. Close ball valves. Repressurize and bleed air

from all test cocks.

Maintenance Instructions

Figure 2

#1 Cam

Check

#2 Cam

Check

Screwdriver

A

B

C

#1 Cam Check

2

1

/

2

" – 6" (65-150mm) RP (Short Cam)

Figure 3

O-ring Seal

& Groove

Seat

Clapper

Roller

Spring

Cam Arm

Figure 4

#2 Cam Check DC & RP

O-ring Seal

& Groove Lug

Seat

O-ring Seal & Groove

Clapper

6" Only

Roller

Cam Arm

Spring

Figure 5A

Cam Bar Open Pin

Valve Outlet Flange

Threaded Stud on Flange

6" (150mm) 1st Check DC

6" (150mm) 2nd Check

DC & RP

Figure 5B

Cleaning

Position

For repair kits and parts, refer to our Backflow Pre-

vention Products Repair Kits & Service Parts price list

PL-A-RP-BPD found on

www.amesfirewater.com.