2

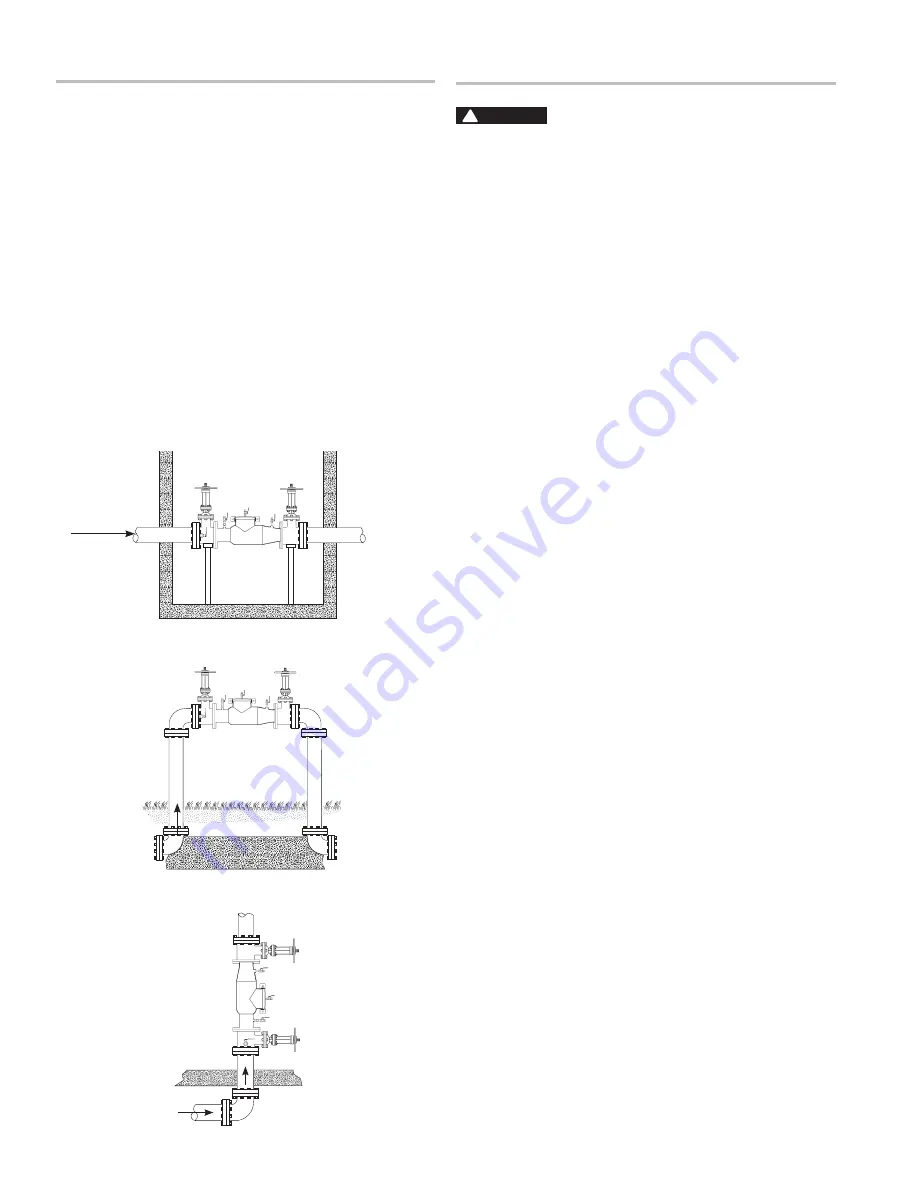

Outdoor Installation

1. Before installing any Ames assembly, Flush the Line thoroughly

to remove all debris, chips and other foreign objects. Failure to

do so may make the assembly inoperable.

2. The Ames 2000SS and 3000SS Backflow Preventers are ap-

proved by ASSE (American Society of Sanitation Engineers) to

be installed in horizontal or vertical positions as long as the flow

indicator arrow in the assembly is pointed in the direction of

water flow. Local water authorities must approve all installation

configurations.

3. Allow sufficient clearance around the installed assembly to

conduct testing, servicing, and inspection. Allow a minimum of 12”

from the flood level to the bottom of the assembly.

4. If double check or double check detector assembly is installed in a

vault or pit, be sure proper drainage is available. If sufficient drain-

age is not available a cross-connection may occur.

5. If installing on fire protection system, be sure to purge air from

fire system. Fill system slowly with all inspectors test valves

open.

Installation Guidelines

Indoor Installation

Vertical Installation ASSE

WARNING

!

Depressurize valve before servicing.

Removing Cam-Checks

1. Shut down water system and lock out system if possible. Slowly

open all ball valves to relieve air and water pressure. Loosen

bolts on groove coupler and remove groove coupler and cover

plate from valve body.

2.

#1 CHECK (Fig. 2)

Using a

9

/

16

” socket wrench or nut driver, remove the four nuts

from the #1 check studs (See Fig.1). Using two hands, placing

them at 12 o’clock and 6 o’clock, wiggle the check assembly

free. Remove through access port with back of clapper first with

spring end down. Pull check assembly out of main body.

#2 CHECK (Fig. 3)

After loosening bolts with a

9

/

16

” socket, remove bolts complete-

ly. Using the centerline access bar, spin the cam assembly from

the 9 o’clock position to the 12 o’clock position, then (without

letting go of the access bar) push the cam assembly slightly

downstream so that the clapper is now parallel to the valve

body. Now bring the cam assembly through the check retaining

wall. Leave the cam assembly clapper parallel to the valve body.

Pull the cam assembly through the access port.

3. Using a

3

/

8

” nut driver or a piece of small diameter pipe, place

on the cam arm torsion spring and move away from and

around the torsion spring retaining bracket so as to relieve the

torsion spring tension. (See Figure 4.) This will allow the cam

arm to move freely, enabling you to inspect the clapper face

and cam seat. Thoroughly clean the seat area and clapper

sealing surfaces, cam arms, and O-rings for damage, nicks,

and debris. If damaged, install a new check assembly O-ring,

or washer, shutoff disk.

4. Reassembly reverse of disassembly, carefully tightening torsion

spring, installing Checks and tightening Studs.

5. Before reinstallation of check assembly, thoroughly clean O-ring

groove and lubricate O-ring with F.D.A. approved lubricant.

Maintenance Instructions