7

Machine Set-up

EN

WARNING:

Always remove the electrical plug from the electrical outlet before installing or

changing the sandpaper.

How To Install The Sandpaper (HydraSand)

To install the sandpaper, follow this procedure:

1. Put the handle in the vertical position.

2. Lock the handle. To lock the handle, push the locking lever down. See figure 1.

3. Tilt the machine backward until the handle is on the floor.

4. Put one foot on each side of the machine.

5. The HydraSand sanding head utilizes hook and loop style sanding paper. Pull off the pad hook the spent

abrasive

6. Replace with new sanding abrasive. See figure 1A.

How To Install The Sandpaper (Alternate Hard Plate)

1. Put the handle in the vertical position.

2. Lock the handle. To lock the handle, push the locking lever down. See figure 1.

3. Tilt the machine backward until the handle is on the floor.

4. Put one foot on each side of the machine.

5. Using a 7/8 wrench, remove the nut and the washer that hold the paper holder.

See figure 2.

6. Put the sandpaper on the sanding pad.

7. Put the paper holder in position. See figure 3.

8. Install the washer and the nut that hold the paper holder.

Two Speed Selection

This machine comes equipped with a selector switch for 175 or 300 RPM operation.

See figure 4 for location of speed switch.

175 RPM speed selection is for use with finer grit sanding abrasive (100 grit or greater) to help reduce the effects

of abrasive heat on the wood that can lead to closing wood pours and discoloration from burnishing the woods

surface. This speed is also used for buffing and polishing.

300 RPM operation will yield the greatest wood removal and productivity and can successfully be used with

more course grit abrasives. (80 grit or below)

CAUTION:

Wood species differ greatly in their sanding characteristics, always test the speed

selection with any grit abrasive used to understand how the wood will react. The general guidelines

given here may not be appropriate for your conditions.

CAUTION:

Do not use the 175 RPM setting for 80 grit or lower. This could result in an over-current

condition.

Sanding Cuts and Sandpaper

Initial Cut

The purpose of the initial cut is to remove old finish and gross imperfections on the floor surface. A coarse

abrasive should be used.

If glazing, loading, or burning takes place immediately into an initial cut, select a coarser abrasive. If this should

occur during an initial cut, the abrasive has dulled and must be replaced.

Final Cuts

The purpose of a finishing cut is to remove the scratches produced during the initial cut. Use a fine (60-80 grit)

grain abrasive.

If the surface remains rough after a finishing cut, it may be necessary to use an even finer grain of abrasive (80-

100 grit). Care should be taken in selecting the grit size of the abrasive. A very fine grain will close the pores on

a wood floor making admission of a stain difficult. Note some finer grain abrasives may begin to heat the woods

surface and burnish the wood grain. use the low motor speed to help avoid this result.

Figure 2

Figure 1

Figure 1A

Figure 4

Figure 3

Содержание American Sanders Epoch HD

Страница 1: ...Epoch HD 230V Dual Speed Rotary Sander Operator s Manual ...

Страница 4: ...4 EN ...

Страница 5: ...5 EN ...

Страница 12: ......

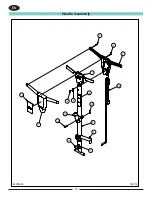

Страница 18: ...18 Handle Assembly EN RF078800 100719 4 4 2 10 16 6 5 13 15 14 3 8 9 11 12 1 7 ...

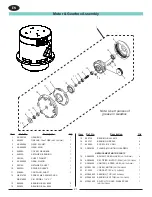

Страница 20: ...20 Connection Diagram EN ...

Страница 24: ...24 Wiring Diagram EN ...