24

When installing a new filter or reinstalling an old one,

always make certain the air flow arrows on the filter point

in the proper direction. If using the unit filter rack, the

airflow arrows must point toward the indoor blower.

To inspect the filter in the filter rack, proceed as follows:

1. Disconnect power to the unit.

2. Locate the filter access door (Figure 9) and remove

the four sheet metal screws.

3. Pull out the filter and inspect. Clean or change as

necessary.

4. Insert the filter into the filter rack channels and lower

into place. Make sure the filter slides completely to

the bottom so no part of the filter is left outside the

back panel.

5. Return the filter access door to its original position

and secure it with the four sheet metal screws.

6. Reconnect the power.

Maintaining Cabinet Finish

Use a fine grade automotive wax on the cabinet finish to

maintain the original high luster. This is especially im-

portant in areas with high ultraviolet radiation.

Clean Outside Coil (Qualified Servicer Only)

The coil with the outside air flowing over it should be

inspected annually and cleaned as frequently as neces-

sary to keep the finned areas free of lint, hair and de-

bris.

Blower Motor

The air circulating blower motor bearings are perma-

nently lubricated.

Figure 21

Blower Motor and Housing

(NOTE: Brushless Permanent Magnet (BPM) blower mo-

tors are permanently lubricated and do not have oil ports.

Oil cannot be added to these motors.

Induced Draft Motor Lubrication

The induced draft motor is permanently sealed and does

not require additional oiling.

XIII. Maintenance

WARNING

To avoid personal injury or death due to

electrical shock, disconnect electrical

power before performing any mainte-

nance.

Important Note: Touching the ignitor body with bare fin-

gers, rough handling, or vibration could result in early

ignitor failure. Only a qualified servicer should ever

handle the ignitor.

Have the furnace checked at least once a year before

the heating season begins, to be sure that the combus-

tion air inlet and flue outlet hoods are not blocked by

debris, which would prevent adequate combustion air

and a properly operating vent system.

Replacing Or Cleaning Filter

A return air filter is not supplied with this unit; however,

there must be a means of filtering all of the return air.

The filter(s) may be located in the return air duct(s), re-

turn air filter grille(s) or in the filter rack in the unit. Con-

sult with your installing dealer for the actual location of

the return air filter(s) for your unit.

Dirty filters are the most common cause of inadequate

heating or cooling performance. Filter inspection should

be made at least every two months; more often if nec-

essary because of local conditions and usage.

Dirty throwaway filters should be discarded and replaced

with a new, clean filter. Dirty permanent filters should be

washed with water, thoroughly dried and sprayed with a

filter adhesive before being reinstalled. (Filter adhesives

may be found at many hardware stores.) Permanent fil-

ters should last several years. However, should one

become torn or uncleanable, it should be replaced.

If the installation has the return air filter located in the

unit filter rack and it must be replaced, use the appropri-

ate Amana filter or a permanent filter that is properly

sized as follows:

Model

Amana Part #

Required Permanent

Filter Size

PGC24, 30, or 36

C4855623

26" X 20" X 1"

PGC42, 48, 60

or PGB58

C4855627

32-5/8" X 22-3/8" X 1"

Содержание PGB58B

Страница 8: ...8 Figure 1 Required Clearances For All Installations...

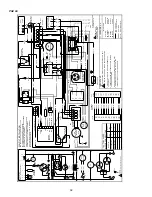

Страница 29: ...29 XVI Wiring Diagram PGC24 36...

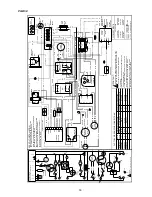

Страница 30: ...30 PGC 42...

Страница 31: ...31 PGC 48...