23

Burner Flame

T

O

AVOID

PERSONAL

INJURY

OR

DEATH

,

DO

NOT

REMOVE

ANY

INTERNAL

COMPARTMENT

COVERS

OR

ATTEMPT

ANY

ADJUSTMENT

.

E

LECTRICAL

COMPONENTS

ARE

CONTAINED

IN

BOTH

COMPARTMENTS

.

C

ONTACT

A

QUALIFIED

SERVICE

AGENT

AT

ONCE

IF

AN

ABNORMAL

FLAME

APPEARANCE

SHOULD

DEVELOP

.

WARNING

Safety Circuit Description

General

A number of safety circuits are employed to ensure safe and

proper furnace operation. These circuits serve to control any

potential safety hazards and serve as inputs in the monitoring

and diagnosis of abnormal function. These circuits are contin-

uously monitored during furnace operation by the integrated

control module.

Integrated Control Module

The integrated control module is an electronic device which

controls all furnace operations. Responding to the thermostat,

the module initiates and controls normal furnace operation,

and monitors and addresses all safety circuits. If a potential

safety concern is detected, the module will take the neces-

sary precautions and provide diagnostic information through

an LED

Red LED Flash

Error / Condition

1

System Lockout (Retries Exceeded)

2

Pressure Switch stuck Closed

3

Pressure Switch stuck Open

4

Open Main or Auxillary Temperature Limit Switch

5

Flame Sensed>4.25 Seconds with Gas Valve De-Energized

6

Open Rollout Temperature Limit Switch

8

Igniter Relay Fault

10

Open Fuse

11

Igniter Open

12

Inducer Relay Error

7

Low Flame Sense Signal

9

Twinning Fault

OFF

Control Failure / No Power / Internal Fault / IRQ Loss. Gas Heating Lockout

(Gas valve energized when it should be de-energized) Or Gas Valve De-

energized when it should be Energized

Rapid Flash

Reverse Polarity

Continuous On Normal Operation

ERROR CODE

Flash Codes stored in memory (auto-erased after 14 days)

Flash Codes NOT stored in memory

.

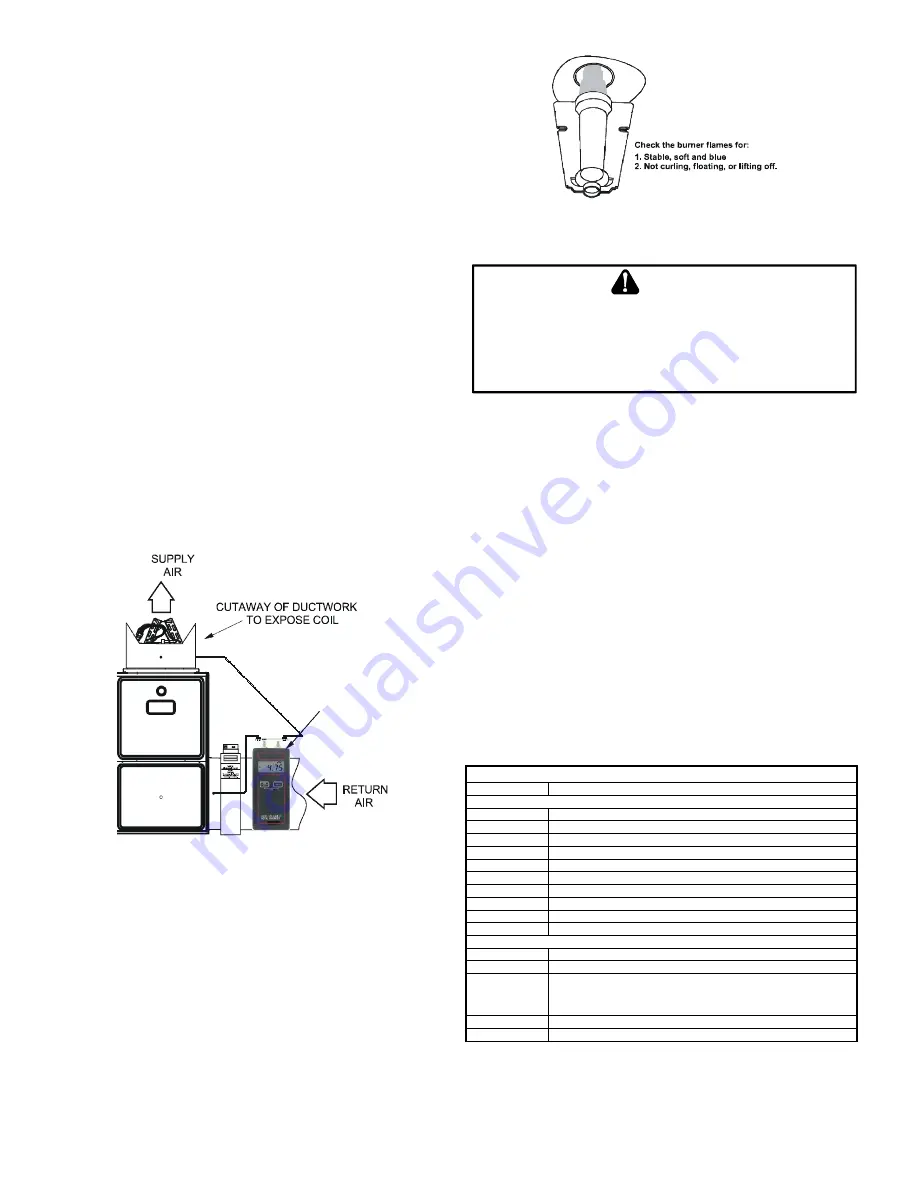

Excessive external static pressure will result in insufficient air

that can cause excessive temperature rise. This can cause

limit switch tripping and heat exchanger failure.

To determine total external duct static pressure, proceed as

follows;

1. With clean filters in the furnace, use a draft gauge

(inclined manometer) to measure the static pressure

of the return duct at the inlet of the furnace. (Negative

Pressure)

2. Measure the static pressure of the supply duct. (Positive

Pressure)

3. The difference between the two numbers is .4” w.c.

Example:

static reading from return duct = -.1” w.c.

static reading from supply duct = .3” w.c.

total external static pressure on this system = .4” w.c.

NOTE:

Both readings may be taken simultaneously and read

directly on the manometer if so desired. If an air conditioner

coil or Electronic Air Cleaner is used in conjunction with the

furnace, the readings must also include theses components,

as shown in the following drawing.

4. Consult proper tables for the quantity of air.

If the total external static pressure exceeds the maximum listed

on the furnace rating plate, check for closed dampers, regis-

ters, undersized and/or oversized poorly laid out duct work.

Digital

Manometer

Checking Static Pressure

Burner Flame

The burner flames should be inspected with the burner

compartment door installed. Flames should be stable, quiet,

soft, and blue (dust may cause orange tips but they must not

be yellow). Flames should extend directly outward from the

burners without curling, floating, or lifting off. Flames must

not impinge on the sides of the heat exchanger firing tubes.

Содержание CES80

Страница 39: ...39 THIS PAGE INTENTIONALLY LEFT BLANK...