3

2.2 Handling

Use caution when transporting/carrying the unit. Do not

move unit using shipping straps. Do not carry unit with

hooks or sharp objects. The preferred method of carrying

the unit after arrival at the job site is to carry via a two-

wheel hand truck from the back or sides or via hand by

carrying at the cabinet corners.

3

Codes & Regulations

This product is designed and manufactured to comply with

applicable national codes. Installation in accordance with such

codes and/or prevailing local codes/regulations is the respon-

sibility of the installer. The manufacturer assumes no respon-

sibility for equipment installed in violation of any codes or regu-

lations.

The United States Environmental Protection Agency (EPA)

has issued various regulations regarding the introduc-

tion and disposal of refrigerants. Failure to follow these

regulations may harm the environment and can lead to

the imposition of substantial fines.

Should you have any

questions please contact the local office of the EPA and/or

refer to EPA’s website www.epa.gov.

4

Replacement Parts

When reporting shortages or damages, or ordering repair parts,

give the complete product model and serial numbers as

stamped on the product. Replacement parts for this product

are available through your contractor or local distributor. For

the location of your nearest distributor consult the white busi-

ness pages, the yellow page section of the local telephone

book or contact:

CONSUMER AFFAIRS

GOODMAN MANUFACTURING COMPANY, L.P.

7401 SECURITY WAY

HOUSTON, TEXAS 77040

(877) 254-4729

5

Pre-Installation Considerations

5.1 Preparation

Keep this document with the unit. Carefully read all in-

structions for the installation prior to installing product.

Make sure each step or procedure is understood and any

special considerations are taken into account before start-

ing installation. Assemble all tools, hardware and supplies

needed to complete the installation. Some items may need

to be purchased locally. Make sure everything needed to

install the product is on hand before starting.

5.2 System Matches

The entire system (combination of indoor and outdoor

sections) must be manufacturer approved and Air-Condi-

tioning, Heating, and Refrigeration Institute (AHRI) listed.

NOTE:

Installation of unmatched systems is not permit-

ted and will void the product warranty.

5.3 Interconnecting Tubing

Give special consideration to minimize the length of re-

frigerant tubing when installing air handlers. Refer to Re-

mote Cooling/Heat Pump Service Manual RS6200006,

and TP-107 Long Line Set Application R-410A for tubing

guidelines. If possible, allow adequate length of tubing

such that the coil may be removed (for inspection or clean-

ing services) from the cabinet without disconnecting the

tubing.

5.4 Clearances

The unit clearance from a combustible surface may be

0". However, service clearance must take precedence.

A minimum of 24" in front of the unit for service clear-

ance is required. Additional clearance on one side or top

will be required for electrical wiring connections. Consult

all appropriate regulatory codes prior to determining final

clearances. When installing this unit in an area that may

become wet (such as crawl spaces), elevate the unit with

a sturdy, non-porous material. In installations that may

lead to physical damage (i.e. a garage) it is advised to

install a protective barrier to prevent such damage. Al-

ways install units such that a positive slope in conden-

sate line (1/4" per foot) is allowed.

5.5 Horizontal Applications

If installed above a finished living space, a secondary

drain pan (as required by many building codes), must be

installed under the entire unit and its condensate drain

line must be routed to a location such that the user will

see the condensate discharge.

6

Installation Location

NOTE:

These air handlers are designed for

indoor installa-

tion only

.

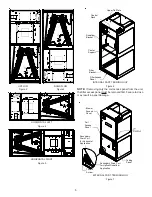

The AVPTC**14** product line may be installed in one of the

upflow, downflow, horizontal left or horizontal right orienta-

tions as shown in Figures 2, 3, 4 and 5. The unit may be

installed in upflow or horizontal left orientation as shipped (refer

to specific sections for more information).

Minor field modifications are necessary to convert to downflow

or horizontal right as indicated in below sections.

6.1 Upflow Installation

No field modifications are mandatory however to obtain

maximum efficiency, the horizontal drip shield must be

removed.

Drip Shield Removal:

Refer to Figure 1, remove the two

(2) screws that secure the drip shield support brackets to

the condensate collectors (one screw per side). Remove

the two (2) screws that secure the drip shield to the drain

pan. The drip shield and drip shield brackets may now

be removed.