PRODUCT DESIGN

39

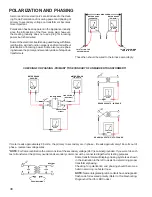

HUMIDIFIER WIRING

Accessory wiring connections are to be made through the

1/4" quick connect terminals provided on the furnace inte-

grated control module.

The Humidifier and Electronic Air

Cleaner hot and neutral terminals are identified as HUM

and EAC. All field wiring must conform to applicable codes.

Connections should be made as shown below.

ELECTRONIC

AIR CLEANER

HUMIDIFIER

OPTIONAL

ACCESORIES

12 PIN

CONNECTOR

120 VAC

NEUTRAL

TERMINALS

N

E

U

T

R

A

L

HU

M

-H

EA

C

-H

120 VAC

HOT AND

PARK

TERMINALS

INTEGRATED

CONTROL

MODULE

Accessory Wiring

(certain control boards)

If it is necessary for the installer to supply additional line

voltage wiring to the inside of the furnace, the wiring must

conform to all local codes, and have a minimum tempera-

ture rating of 105°C. All line voltage wire splices must be

made inside the furnace junction box.

The integrated control module humidifier terminals (HUM)

are energized with 115 volts whenever the induced draft

blower is energized. The integrated control module elec-

tronic air cleaner terminals (EAC) are energized with 115

volts whenever the circulator blower is energized.

24 VOLT THERMOSTAT WIRING

NOTE:

Low voltage connections can be made through ei-

ther the right or left side panel. Wire routing must not inter-

fere with circulator blower operation, filter removal, or rou-

tine maintenance.

A 40 V.A. transformer and an integrated electronic control

are built into the furnace to allow use with most cooling

equipment. Consult the wiring diagram, located in the Tech-

nical Manual or on the blower door for further details of 115

Volt and 24 Volt wiring.

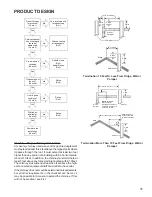

THERMOSTAT WIRING - SINGLE-STAGE

The single stage furnace will have a "W" terminal and will

use a single stage thermostat. The following drawing illus-

trates the typical field wiring for a heat only single stage

system and a single stage heating/single stage cooling sys-

tem. Refer to the following figures for proper connections to

the integrated control module.

Furnace

Control

Furnace

Control

Remote

Condensing

Unit

Heating

Room

Thermostat

Heating/Cooling

Room Thermostat

W

W

Typical Field Wiring (24 VAC Control Circuit)

CONTINUOUS FAN OPERATION

SINGLE STAGE FUR-

NACES

The single stage furnace control will energize the

heating

circulator fan speed when the fan switch on the thermostat

is turned to the "ON" position.

CIRCULATOR BLOWER SPEED ADJUSTMENT

WARNING

HIGH

VOLTAGE

D

ISCONNECT

ALL

POWER BEFOR CHANGING SPEED TAPS.

M

ULTIPLE POWER SOURCES MAY BE PRESENT.

F

AILURE TO DO

SO MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

Connect the correct motor leads to the COOL, HEAT, and

PARK terminals. If the heating speed equals cooling speed,

use the jumper wire provided. All unused motor leads that

are not connected to "PARK" terminals on the control must

be taped to prevent shorts.

CIRCULATING AIR AND FILTERS

DUCTWORK - AIR FLOW

Duct systems and register sizes must be properly designed

for the C.F.M. and external static pressure rating of the fur-

nace. Ductwork should be designed in accordance with the

recommended methods of "Air Conditioning Contractors of

America" manual D.

A duct system should be installed in accordance with Stan-

dards of the National Board of Fire Underwriters for the In-

stallation of Air Conditioning, Warm Air Heating and Venti-

lating Systems, Pamphlets No. 90A and 90B.

A return air filter is not supplied with the furnace. The in-

staller must supply a means of filtering all of the return air.

Filter(s) shall comply with UL900 or CAN/ULC-S111 Stan-

dards.