HubWayEX16SP Active Unit

- 3 -

• For 24VAC cameras use Altronix model HubWayAv Video Balun/Combiner (Fig. 3a, pg. 5).

• For 12VDC cameras use Altronix model HubWayDv Video Balun/Combiner (Figs. 3b, pg. 5).

Repeat steps 6-9 for each additional camera (Channels 2-16 for HubWayEX16SP).

Note: When a particular camera exceeds the maximum distance for power transmi ssion, a local

external power source is required. Optionally, an Altronix HubSat4D/Di Passive UTP Transceiver Hub with Integral

Camera Power may be utilized (Fig. 5, pg. 6).

The combined total cable distance must not exceed 5000 ft. for video transmission between the

HubWayEX16SP and each camera routed through the HubSat4D/4Di Remote Accessory Module

(refer to HubSat4D/Di installation instructions).

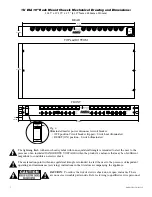

10. Set illuminated master power disconnect circuit breaker to the RESET (ON) position (Fig. 6, pg. 7) and measure

the output voltage at the power output of each Video Balun/Combiner (Figs. 3a, 3b, pg. 5) before powering each

camera to ensure proper operation and avoid possible damage.

• HubWayAv - Terminals marked [AC POWER] (Fig. 3a, pg. 5).

• HubWayDv - Terminals marked [– 12VDC +] (Fig. 3b, pg. 5).

11. Set illuminated master power disconnect circuit breaker to the (OFF) position to make the final connections

(Fig. 6, pg. 7).

12. Connect the power outputs of the HubWayAv or HubWayDv Video Balun/Combiners to the power inputs of the

cameras

(Figs. 3a-3b, pg. 5). Polarity must be observed.

13. Connect the terminals marked [+ DATA -- ] of the HubWayAv or HubWayDv Video Balun/Combiners to the data

terminals of the cameras for PTZ control (Figs. 2a-2d, pg. 5). Polarity must be observed.

When using fixed cameras disregard this step.

14. Connect the BNC connector of the HubWayAv or HubWayDv Video Balun/Combiners to the

BNC video outputs of the cameras (Figs. 3a-3b, pg. 5).

15. Upon completion of wiring set illuminated master power disconnect circuit breaker to the RESET (ON) position

(Fig. 6, pg. 7).

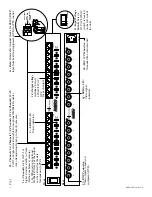

16. The power LEDs (Red) located on the front of the HubWayEX16SP will illuminate when AC power

is present (Fig. 1c, pg. 4).

Note: If any of these LEDs are not illuminated either a voltage output selector switch is in the OFF position or the

PTC is tripped for that channel.

To reset the PTC:

1. Set the voltage output selector switch for that corresponding channel to the OFF position. Switch must remain

in the OFF position for approximately 2 minutes in order for the PTC to reset.

2. Eliminate the trouble condition (short circuit or overload).

3. Set the voltage output selector switch for 24VAC or 28VAC (Fig. 1d, pg. 4).

17. AC LED (Green) of the HubWayAv or DC LED (Red) of the HubWayDv Video Balun/Combiners

will illuminate indicating power is present at the cameras (Fig. 3a, 3b, pg. 5).

18. The video signal indicator LEDs (Red) located on the rear of the HubWayEX16SP will illuminate when

video signal is present (Fig. 1g, pg. 4). If any of these LEDs are not illuminated, no video signal is present for

that corresponding channel.