38

Rockwell Automation Publication 750-IN020D-EN-P - May 2017

PowerFlex 755 IP00, NEMA/UL Open Type Drive

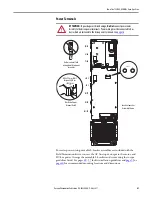

Horizontal Lifting

Recommended Lifting Bar (User Supplied)

Lifting Hardware

Drive Installation

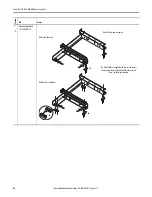

Preparing the Enclosure

To facilitate ease of service, it is recommended that the drive assembly be

mounted on support rails such as the Floor/Rail kit described on

or

. Fasten rails to the enclosure at distances shown on

For proper internal cooling airflow, a minimum mounting clearance of 51 mm

(2.0 in.) to the side walls is required.

The drive assembly should be secured to the rear of the enclosure or full size

control panel using the Mounting kit described on

.

Recommended placement and dimensions for the kit are provided on

or

. Brackets are supplied on the drive assembly for attaching the Mounting

kit components. The Mounting kit is required to prevent mechanical damage to

the power terminals.

714.

8

(2

8

.14)

1429.4 (56.2

8

)

15

8

5.9 (62.44)

1

8

2

8

.

8

(72.00)

734.0 (2

8

.90)

659.2 (25.95)

556.5 (21.91)

47.6 (1.

88

)

22.2 (0.

88

)

199.6 (7.

8

6)

12.7 (0.50) Min.

69.9 (2.75) Min.

12.7 (0.50) Dia.

6 places

Recommended Material: AISI C1018 or ASTM A36

Hardness: 66 HRB minimum

Minimum Working Load: 318 kg (700 lb)

15

8

5.9 (62.44)

1

2

3

416.9 (16.41)

Lifting Hole Descriptions

1. 1. Drive with DC link choke.

2. Drive without DC link choke, inverter only without DC link choke, or common DC input drive.

3. Inverter only without DC link choke.

ATTENTION:

To guard against personal injury and/or equipment damage,

ensure that the enclosure and drive assembly is properly supported to prevent

tipping.