36

Fuel Filter

Fuel Filter

Specifications, Trouble Shooting

FIL

FIL

FIL

FIL

FILTER,

TER,

TER,

TER,

TER, FUEL

FUEL

FUEL

FUEL

FUEL

P/N V04-00308

REMEDY

1. Fuel bowl leaking.

2. Air leaking into system

(indicated by air bubbles in bowl

during operation).

A. Deteriorated gasket.

B. Housing Cracked.

C. Bowl rim cracked, nicked, or scratched.

D. Gasket missing.

E. Loose Fuel Bowl.

A.Loose Valve Assembly.

B. craked Component.

C. loose Filter bowl.

A. Remove and Replace Gasket.

B. Remove and Replace Housing.

C. Remove and Replace Bowl.

D. Replace Gasket.

E. Tighten Fuel Bowl Onto Filter.

A.Tighten Valve Assembly.

B. Inspect Filter Bowl, Filter Housing,

and Gasket.

C. Tighten Fuel Bowl Onto Fuel Filter.

TROUBLE

POSSIBLE CAUSE

TR

TR

TR

TR

TROUBLE SHOO

OUBLE SHOO

OUBLE SHOO

OUBLE SHOO

OUBLE SHOOTING

TING

TING

TING

TING

•

MAXIMUM FLOW

15 GPH / 57 LPM

• MAXIMUM FILTRATION

2 MICRONS

• MAXIMUM TEMPERATURE

212°F / 100°C

• WEIGHT

1.0 LBS. / 340 GM

• INLET

1/4 NPT

• OUTLET

1/4 NPT

SPECIFICA

SPECIFICA

SPECIFICA

SPECIFICA

SPECIFICATIONS

TIONS

TIONS

TIONS

TIONS

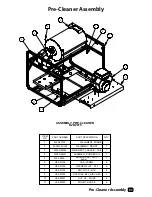

3 1/4"

5 1/2" (6 1/2" Required For

Element Removal)

Inlet

Vent Plug

Drain Port

Outlet

ALL DIMENTIONS ARE

IN INCHES UNLESS OTHERWISE

NOTED. 25.4 MM = 1 INCH

Specifications

Maximum Flow

15 GPM / 57 LPM

Maximum Filtration

2 Microns

Maximum Temperature

212˚F / 100˚C

Weight

1.0lbs / 340km

Inlet

¼ NPT

Outlet

¼ NPT

All dimensions are in inches unless otherwise noted.

25.4 mm = 1 inch

Maintenance Procedures

Priming the machine

Shut off the fuel tank valves. Spin off the clear bowl, fill with clean fuel and coat the round gasket (3)

with fuel. Reinstall the clear bowl and tighten ¼ to 1/3 turns after the gasket contacts the upper housing.

Turn on the fuel tank valves. Start the machine and check that there are no leaks.

Draining water

Check the collection bowl daily. Drain off water contaminants by unscrewing the clear bowl turning

counter-clockwise. Start the machine and allow air to purge from the fuel system prior to operating the

equipment.

Element replacement frequency

Frequency of element replacement is determined by contamination level in the fuel. Replace the

element every 500 hours.

Note: Foul smelling diesel fuel is an indication of microbiological contamination. A change in fuel source

is recommended. Always carry a spare filter element as one tank full of contaminated fuel will plug the

fuel filter element prematurely.

Element replacement procedure

1. Shut off the fuel tank valves.

2. Unscrew the clear bowl turning counter-clockwise.

3.

Remove and discard the filter element.

4. Follow listed procedures under “PRIMING.”

Filter, Fuel

p/n V04-00308

Содержание 5305A

Страница 4: ...Month Day Year Operating Hours Maintenance Performed Machine Record...

Страница 9: ...5 Trigger Gun Wand 11 Gun Wand Assembly...

Страница 14: ...10 Control Panel 31 Coil Outlet Metering Valve Assembly...

Страница 17: ...13 Meteing valve Valve Metering...

Страница 42: ...38 Burner Burner Exploded View 4 Water Pump...

Страница 51: ...47 Tank Assembly...

Страница 53: ......

Страница 54: ......

Страница 55: ......