11

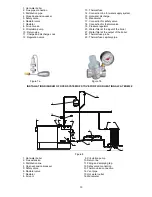

- It is desirable to insert a pump R1" for more speed whose flow capacity is always appropriate for the current

need of the system. Directly in front and behind the pump, install shut-off valves so that displacement of the

pump could be performed for repairs, changes etc., without releasing water.

- Mount a tap for the filling and draining the system at the lowest system point.

- Before commissioning the system should be filled with water as follows:

a) If the system is open, fill the system through the tap for filling and draining until water starts to leak

from the overflow pipe of the expansion vessel,

b) If the system is closed, the system pressure (working pressure) should be 1

1,5 bar.

In both cases, fill the system slowly so that air can come out through the air releasing valves. If the valves do

not open themselves, they should be manually open until water starts to leak, than close them.

- The water from the heating system should not be drained in summer neither since it protects the internal

side of the system from spreading oxidation (corrosion).

-

If you don’t use the boiler for a longer period in winter, and there is not antifreeze asset in the system, it is

best to drain the water from the system. At the same time open the valves on the radiators, the combined

valves and the other shut-off elements in the system.

- Fire must not be kindled if the water in the boiler is frozen, neither if there is not enough water in the boiler.

8. COMMISSIONING AND STOKING

Before stoking, the entire system for floor (central) heating should be filled with water, well vented and the

stove should be properly connected to the flue as explained in the previous paragraphs.

WARNING:

The stove must not be used without water. It must be connected to an installation on which

consumers (radiators) are connected with a minimum power of 8 kW.

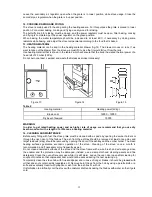

When the system is cold, the flap of the power regulator (combustion regulator, thermostat) located in the

ashtray door (fig.1 pos.10 and pos.19) should be open. Pull ahead the butterfly knob for opening and closing

(fig. 1 pos.4 and fig. 16). That way the butterfly knob is open and kindling is enabled. Later when the stove is

inflamed, we adjust the regulator flap on the appropriate position that depends on the pulling power of the flue

and the desired power, and the butterfly knob should be pushed back. Then the butterfly knob is closed and

full use of the combustion is enabled, thus better heating, cooking and baking. During this, the door of the

firebox and the ashtray (fig. 1 pos. 7 and pos. 9) must be closed if we want regulated combustion. The

butterfly knob for kindling is open only during the kindling of the stove (10 to 15 minutes).

The firebox and ashtray doors can be open and closed manually, as well as with the bent wrench as shown

on figure 6.

We stoke the stove as all permanently burning stoves on solid fuels. When the grade is in lower position, we

perform kindling through the open door of the ashtray and the ember holder (fig.9 and fig.10). We open the

ember holder (fig.1 pos.13 and fig.9) by raising and pulling. When the grate is in upper position through the

open door of the firebox (fig.11) on the grate we put paper, small pieces of chopped wood and kindle. When

everything is burning well, we can fill the stove with wood or coal if the grate is in upper position. If the grate is

in lower position, do not put at once all the needed heating material for full firebox, but divide it on two or

three parts and put it in the firebox at intervals of 10-15 minutes on flaming heating material. The stove filled

in this manner burns from 1 to 6 hours, depending on the intensity of combustion in the stove and the

adjusted power regulator (thermostat).

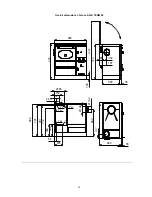

Figure 9

Figure10

Figure 11