© 2004 Alamo Group Inc.

Page 8 - 3

Interstater (NH TS-100A , 115A , 125A & 135A Asy. Manual) 06/04

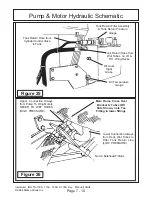

Rear Three Point Mower

Connection:

5.

Leveling the Rear Mower & Adjust gutting

Cutting Height. The Rear Mower is leveled with the

top Three Point Link. The Cutting Height is adjusted

by moving the Roller up or down by change the

bearing bracket mounting hole. The is a decal on the

deck next the Operators/ parts manual cannister

(See Figure 5 & 6)

6.

Rear Mower Completly Connected. With the

rear mower completly connected. Check all Oil lev-

els and grease mower components (See Figure 9)

before running mower. Also DO NOT start tractor if

the rest of the assembly to the interstater is not

done. Make certain that all hoses, compontents,

wiringing is completed and Oil Tank for interstater

has been filled with oil.

7.

Slip clutch is incorporated in the PTO driv-

eline. It is designed to slip, absorb the shock load,

and protect the driveline.

It is important that the

clutch lining plates slip when an obstacle or load

heavier than clutch setting is encountered. There-

fore, if the machine sits outside longer than 30 days

and is exposed to rain and/or humid air it is impor-

tant to make sure that the clutch lining plates are not

rusted/corroded together. Before using the mower

use the following procedure to make sure the clutch

will slip and give the overload protection required.

(See Figure 8) This is a required step because the

driveline has been sitting and may be stuck.

A.

Loosen nuts

on springs until the springs can

freely rotate, yet remain secure on bolts.

B.

Attach mower to tractor and start the tractor.

Set the engine speed at 1200 RPM.

C.

Mark outer plates with marker, paint or any

form that will work for you to tell if the compo

nents of the clutch slipped.

D.

Engage the PTO (approximately one sec-

ond) and then quickly disengage it. The

friction lining plates should break loose

(check the mark).

E.

Turn tractor off and tighten the nuts on the

springs to their original position of 1-5/16"

compressed spring length.

Rear Three Point Mower

Figure 6

Figure 5

Figure 7

Содержание Interstater TS-100A, TS-115A,

Страница 6: ... 2004 Alamo Group Inc Page 0 4 Interstater NH TS 100A 115A 125A 135A Asy Manual 06 04 NOTES ...

Страница 16: ... 2004 Alamo Group Inc Page 2 6 Interstater NH TS 100A 115A 125A 135A Asy Manual 06 04 NOTES ...

Страница 26: ...Interstater NH TS 100A 115A 125A 135A Asy Manual 06 04 2004 Alamo Group Inc Section 3 10 NOTES ...

Страница 38: ... 2004 Alamo Group Inc Page 4 12 Interstater NH TS 100A 115A 125A 135A Asy Manual 06 04 NOTES ...

Страница 42: ... 2004 Alamo Group Inc Page 5 4 Interstater NH TS 100A 115A 125A 135A Asy Manual 06 04 NOTES ...

Страница 56: ... 2004 Alamo Group Inc Page 7 12 Interstater NH TS 100A 115A 125A 135A Asy Manual 06 04 NOTES ...

Страница 64: ... 2004 Alamo Group Inc Page 8 8 Interstater NH TS 100A 115A 125A 135A Asy Manual 06 04 NOTES ...

Страница 70: ... 2004 Alamo Group Inc Page 9 6 Interstater NH TS 100A 115A 125A 135A Asy Manual 06 04 NOTES ...

Страница 71: ......