© 2004

Alamo Group Inc.

Section 3 - 3

Interstater (NH TS-100A , 115A , 125A & 135A Asy. Manual) 06/04

Existing Holes

have rubber

Plugs in them

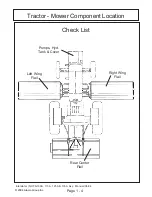

Figure 2

Air After-Cooler

Tractor

Bolster

Cover removed

Figure 3

LH Side Engine

Guards Removed

From Tractor

Pump - Driveshaft - Hyd tank

Install Driveshaft, Pump & Tank:

1.

Gain Access to Tractor Engine. Raise the

hood of the tractor to revel the tractor engine (See

Figure 2). Remove the engine guards on the left

hand side of tractor (See Figure 3). This will allow

you access to the Tractor Crankshaft Pulley. (See

Figure 1). Remove the plate under After cooler which

will make installing driveshaft easier.

2.

Bolt Pulley Adapter to Engine Crankshaft

Pulley. Bolt the pulley adapter to the to the crankshaft

pulley with the supplied bolts. Make certain the bolts

used are not to long or to short (See Figure 1).

3.

Install Driveshaft. Insert driveshaft into crank-

shaft pulley, both splined ends are the same so it will

not matter which end is inserted.

4.

Install pump Mount Weldment. Bolt the pump

mount weldment to the front bolster of the tractor.

The driveshaft will be sicking through the hole in the

pump mount weldment. (See Figure 1)

5.

Install Driveshaft Bearing & Bearing Collar.

Slide the bearing onto the driveshaft until the bearing

is seated into the inner hole of the pump mount

weldment where the driveshaft comes through. Slide

the bearing collar onto driveshaft until seated against

bearing. Making certain that driveshaft is seated into

crankshaft pulley adapter tighten setscrew for bear-

ing collar. (See Figure 1)

6.

Install Drive pulley & Splined sleeve weldment. The drive pulley weldment and drive belt will have

to be installed at the same time. If the drive belt is not installed now you will not be able to later.

7.

Install Hydraulic Pump (Pumps to operate Wing Motors). Install the Tandem Pump (single

pump if only one wing.) By aligning the splines of the pump shaft with the splines of the drive pulley &

splined sleeve weldment. Push the pump on till the pump is seated into the pump mount weldment.

8.

Install Pump Retaining Bolts. Install the two bolts that retain the Left & Right wing pump(s) to

the pump mount weldment and tighten them. (See Figure 1)

9.

Install Small Pump (Hyd Cyl System). The Hyd Cyl operate from a small pump bolted above the

tandem pump. (See Figure 1) Bolt the Pump onto the Small Pump Mount plate with the two mounting

bolts. Install the driven pulley onto the pump, make certain to install the key in pump shaft. DO NOT

tighten the setscrews in pulley until later. Slide the Drive Belt onto driven pulley and align the pump mount

plate with the holes in the pump mount weldment, use Flat washers on bolts to mount to pump mount

weldment (See Figure 4). DO NOT Tighten these bolts yet.

Содержание Interstater TS-100A, TS-115A,

Страница 6: ... 2004 Alamo Group Inc Page 0 4 Interstater NH TS 100A 115A 125A 135A Asy Manual 06 04 NOTES ...

Страница 16: ... 2004 Alamo Group Inc Page 2 6 Interstater NH TS 100A 115A 125A 135A Asy Manual 06 04 NOTES ...

Страница 26: ...Interstater NH TS 100A 115A 125A 135A Asy Manual 06 04 2004 Alamo Group Inc Section 3 10 NOTES ...

Страница 38: ... 2004 Alamo Group Inc Page 4 12 Interstater NH TS 100A 115A 125A 135A Asy Manual 06 04 NOTES ...

Страница 42: ... 2004 Alamo Group Inc Page 5 4 Interstater NH TS 100A 115A 125A 135A Asy Manual 06 04 NOTES ...

Страница 56: ... 2004 Alamo Group Inc Page 7 12 Interstater NH TS 100A 115A 125A 135A Asy Manual 06 04 NOTES ...

Страница 64: ... 2004 Alamo Group Inc Page 8 8 Interstater NH TS 100A 115A 125A 135A Asy Manual 06 04 NOTES ...

Страница 70: ... 2004 Alamo Group Inc Page 9 6 Interstater NH TS 100A 115A 125A 135A Asy Manual 06 04 NOTES ...

Страница 71: ......