14SEER AIR COOLING ONLY SYSTEM TECHNICAL MANUAL

9

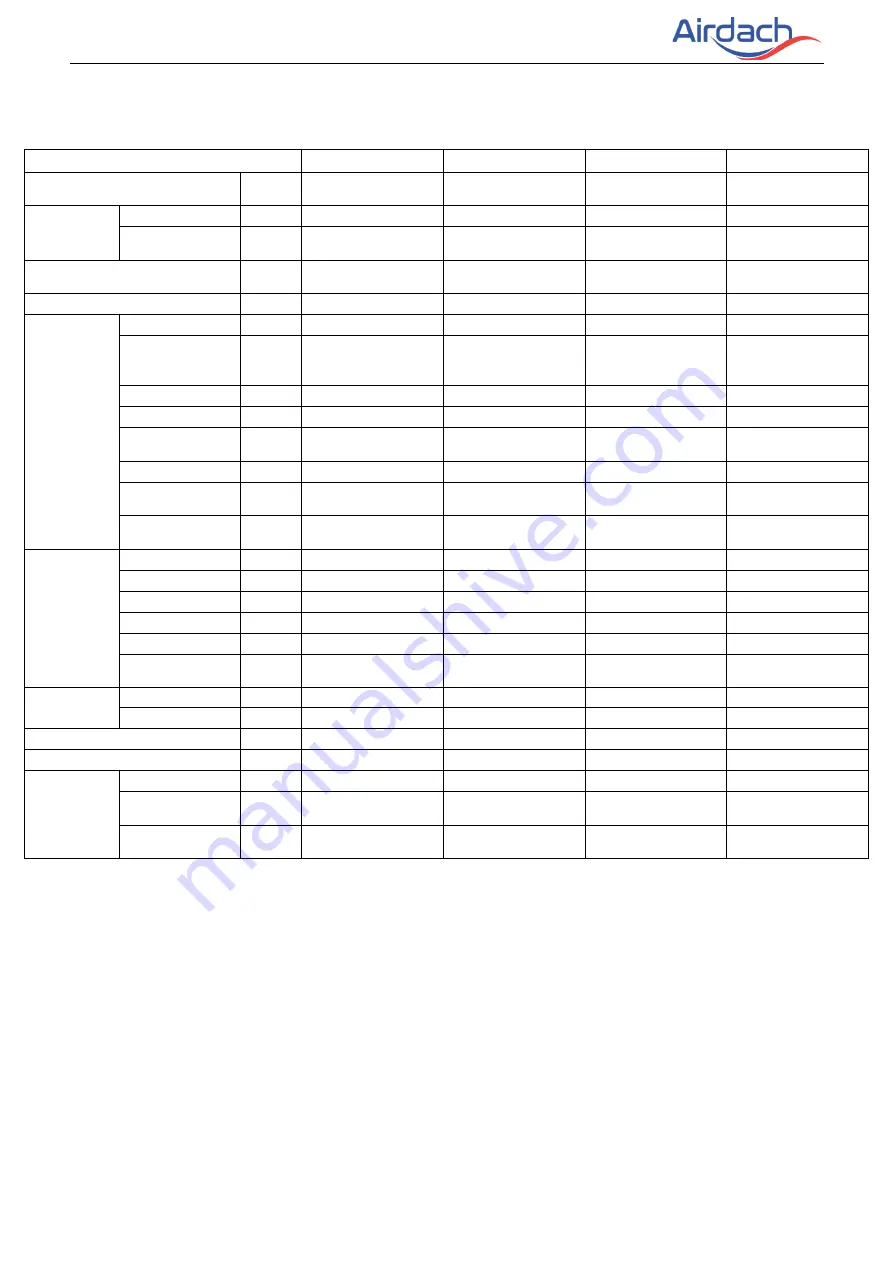

Model

AIDC3600NG1-D

AIDC4200NG1-D

AIDC4800NG1-D

AIDC6000NG1-D

Power supply

V/Ph/

Hz

208~230V/1N/60Hz 208~230V/1N/60Hz 208~230V/1N/60Hz 208~230V/1N/60Hz

Cooling

Capacity Btu/h

34500

42000

48000

56500

SEER

Btu/h.

W

14.00

14.00

14.00

14.00

Indoor external static

pressure

Pa

37

37

50

50

Throttle type

TXV

TXV

TXV

TXV

Indoor coil

Number of row

4(row)×2(piece)

4(row)×2(piece)

5(row)×2(piece)

5(row)×2(piece)

Tube

pitch(a)xrow

pitch(b)

in

0.83×0.53

0.83×0.53

0.83×0.53

0.83×0.53

Fin spacing

in

1/16

1/16

1/16

1/16

Fin material

Hydrophilic

Hydrophilic

Hydrophilic

Hydrophilic

Tube outside

diameter

in

Ф ¼

Ф ¼

Ф ¼

Ф ¼

Tube material

inner grooved

inner grooved

inner grooved

inner grooved

Coil length x

height x width

in

17 7/16×16

17/32×2 7/64

17 7/16×16

17/32×2 7/64

19 27/32×21 1/2×2

5/8

19 27/32×21 1/2×2

5/8

Number of

circuit

8

8

12

12

Indoor fan

motor

Brand

Kangbao

Kangbao

Kangbao

Kangbao

Type

PSC

PSC

PSC

PSC

Input Amp

1.81

2.10

2.63

2.63

Output

Amp

1

1.23

1.36

1.36

Capacitor

μF

10

10

12

12

Speed

(Lo/Me/Hi)

rpm

690/730/805

610/723/839

820/870/920

820/870/920

blower

diameter

in

12-5/16

12-5/16

12-5/16

12-5/16

width

in

12-29/32

12-29/32

12-29/32

12-29/32

Indoor air flow

CFM

1161/1235/1376

1208/1385/1562

1434/1574/1695

1434/1574/1695

Indoor noise level

dB(A)

51

54

55

55

Indoor unit

Unit (HxWxD)

in

45-3/4×19-2/3×22

45-3/4×19-2/3×22

53-1/8×22×24-1/2

53-1/8×22×24-1/2

Packing

(HxWxD)

in

47.63×22.83×25.59

47.63×22.83×25.59

54.72×25.20×27.95

54.72×25.20×27.95

Net/Gross

weight

lbs

134/146

137/148

176/190

176/190

Notes:

1. Nominal cooling capacities are based on the following conditions:

Indoor temp: 80°FDB, 66°FWB; Outdoor temp: 95°FDB; Equivalent ref. piping: 5m (horizontal)

2. Nominal heating capacities are based on the following conditions:

Indoor temp: 68°FDB; Outdoor temp: 44°FDB, 43°FWB; Equivalent ref. piping: 5m (horizontal)

3. Actual noise level may differ, depending on the room structure, etc., since these noise values are from an

anechoic room.

Содержание ACTC1814NG1-D

Страница 4: ...14SEER AIR COOLING ONLY SYSTEM TECHNICAL MANUAL 2 Nomenclature...

Страница 15: ...14SEER AIR COOLING ONLY SYSTEM TECHNICAL MANUAL 13 60K...

Страница 23: ...14SEER AIR COOLING ONLY SYSTEM TECHNICAL MANUAL 21...

Страница 41: ...14SEER AIR COOLING ONLY SYSTEM TECHNICAL MANUAL 39 3 7 High pressure alarm 3 8 T3 High temperature protection...

Страница 42: ...14SEER AIR COOLING ONLY SYSTEM TECHNICAL MANUAL 40 3 9 High exhaust temperature protection...