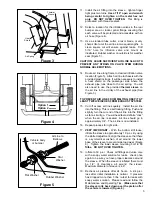

Fig.8 MN 190

Air Line to

Bellows

Star

Washer

Vehicle body

or bumper

Rubber Washer

Flat Washer

Heat

Shield

Air Spring

Thermal

Sleeve

11. Install the air fitting into the sleeve , tighten finger

tight plus two turns.

Use a 7/16” open end wrench

being careful to tighten on the metal hex nut

only. DO NOT OVER TIGHTEN.

This fitting is

precoated with thread sealant.

12. Select a location for the inflation valves in the rear

bumper area or rocker panel flange ensuring that

each valve will be protected and accessible with an

air hose (Figure 4).

13. Use a standard tube cutter, a razor blade, or very

sharp knife to cut the air line in two equal lengths. A

clean square cut will ensure against leaks. Drill

5/16” hole for inflation valve and mount as

illustrated. Rubber washer on outside is for weather

seal (Figure 5).

CAUTION: LEAVE SUFFICIENT AIR LINE SLACK TO

PREVENT ANY STRAIN ON VALVE STEM DURING

NORMAL AXLE MOTIONS.

14. Route air line along frame to desired inflation valve

location (Figure 5). Attach air line to chassis with the

provided plastic straps. It will be necessary to install

a heat shield on the passenger side where the

exhaust pipe runs close to the air spring. You will

also need to use the provided

thermal sleeve

on

the air line in the vicinity of the exhaust pipe (See

Figure 3).

TO PREVENT AIR LINE FROM MELTING, KEEP IT AT

LEAST TWELVE INCHES FROM EXHAUST SYSTEM.

15. Cut off excess air line squarely. Install the air line

into the fitting. This is a self locking fitting. Push and

slightly turn the cut end of the air line into the fitting

as far as it will go. You will hear/feel a definite “click”

when the air line is seated. Air line should go in

approximately 3/4”. The air line is now installed.

16. Repeat process for right side.

17.

VERY IMPORTANT -

With the bottom still loose,

inflate the sleeve to approximately 10 p.s.i. By using

the slotted adjustment, align the sleeve so that there

is a symmetrical cushion of air around the lower

base of the sleeve to prevent side load wear (Figure

6). Tighten the lower sleeve mounting bolt to

10

ft/lbs. DO NOT OVER TIGHTEN.

18. Inflate to 30 p.s.i. Check all fittings and valve core

with a soapy water solution for leaks. check once

again to be sure you have proper clearance around

the sleeve. When the sleeve is inflated there must

be 1/2” of clearance all around the sleeve.

Maximum diameter of sleeve is 4.6”.

19. Recheck air pressure after 24 hours. A 2-4 p.s.i.

loss after initial installation is normal. If pressure

has dropped more than 5 lbs. re-test for leaks with

soapy water solution. Please read and follow the

Maintenance and Operating Tips.

(Make sure that

the sleeve rolls back down over the piston after

the vehicle is lowered (Figure 6).

Figure 3

Figure 5

3

Option 1

Option 2

Figure 4