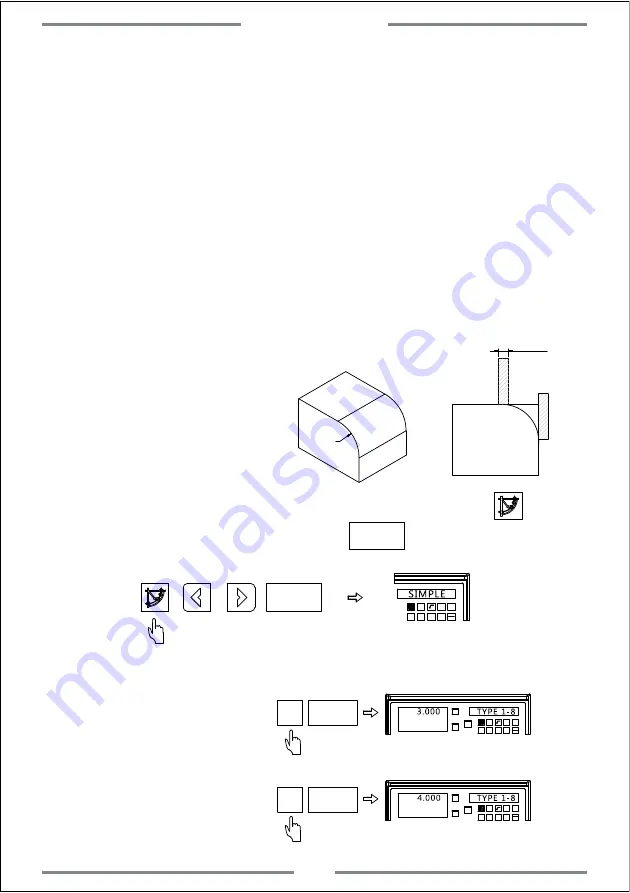

Example:Machine the arc as

shown in right figure.

Operation steps

1. Locate the zero point of work-piece and zero the value of axis

2. Enter the R function and select the simple R (SIMPLE)

3. Select the machining way from the preset 8 options.(TYPE 1-8)

4. Select the plane XY,XZ,YZ(ARC-XY,ARC-XZ,ARC-YZ)

5. Input the arc radius (R)

6. Input the tool diameter (TL-DIA) Note:When using the flat end mill to

machine the arc on plane of XZ and YZ,input the tool diameter as 0)

7. Input the maximum cutting amount (MAX-CUT)

8. Select the arc plane as convex or concave(RAD+RL or RAD-RL)

9. Machining the point by turn according to the DRO display.

R10

A

B

∅

5

Step 1: Move the tool to the starting point of arc(A or B),press to enter

the R function and select simple R.Press to confirm.

E T

E T

1

3

2

-

+

CLS

Arc

sin

TOOL

3

E T

X

0

Y

0

X

1

3

2

-

+

CLS

Arc

sin

TOOL

Step 2: Select the machining way

A as the starting point

4 E T

X

0

Y

0

X

1

3

2

-

+

CLS

Arc

sin

TOOL

B as the starting point

Special Function

31

Содержание A20-2V

Страница 1: ...LED DIGITAL READOUTS Operation Manual Version 2 0 Driven by Innovation...

Страница 2: ...A20 3V Keypad A20 2V Keypad ENT T ENT T E N N T E N N T...

Страница 54: ...1 Parameter 2 Dimension 3 Troubleshooting 5 Appendix Appendix...

Страница 56: ...5 2 Dimension ENT T T 45 Appendix...

Страница 59: ...Driven by Innovation X 0 Y 0 Z 0 X Y Z Operation Manual Version 2 0 DIGITAL READOUTS...