29

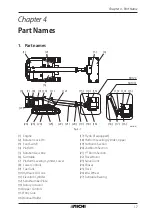

Set the boom stand (fi g. 7‒6, B) and the

wood block (fi g. 7‒6, A) to prop up the fi rst

boom end. Use the wood block that is wider

than the width of fi rst boom end.

Avoid the tie-down ring (fi g. 7‒6, C), and

center the fi rst boom end on the wood

block.

Make sure the stand is stable.

M085K102

(A)

(B)

(C)

fi g. 7‒6

WARNING

Fixate the stand with brace members so

that the stand does not fall over during

operation.

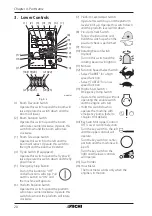

Using the lower controls, lower the boom

to lift up the track 30〜50 mm above the

ground. (fi g. 7‒7)

M085K201

30mm~50mm

fi g. 7‒7

WARNING

Do not lift up the track more than

50mm above the ground. Lifting up the

track more than needed could cause the

machine to become unstable. Death or

serious injury could result.

Push in the emergency stop button to stop

the engine. Turn the key switch to “OFF” and

remove the key.

WARNING

Never leave the key in the key switch

when adjusting the tension of the

tracks. Someone may accidentally start

the engine without realizing it while

adjusting the tension of the tracks. Such

accidents could result in a serious injury.

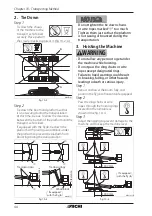

A grease fi tting (fi g. 7‒8, A) is located on

the right and left sides of the chassis frame.

Supply grease to the grease cylinder through

the grease fi tting to adjust the tension of the

track. Adjust the tension of the track so that

there is 115〜125 mm of slack between the

chassis frame and track link. (fi g. 7‒9)

M085K401

(A)

fi g. 7‒8

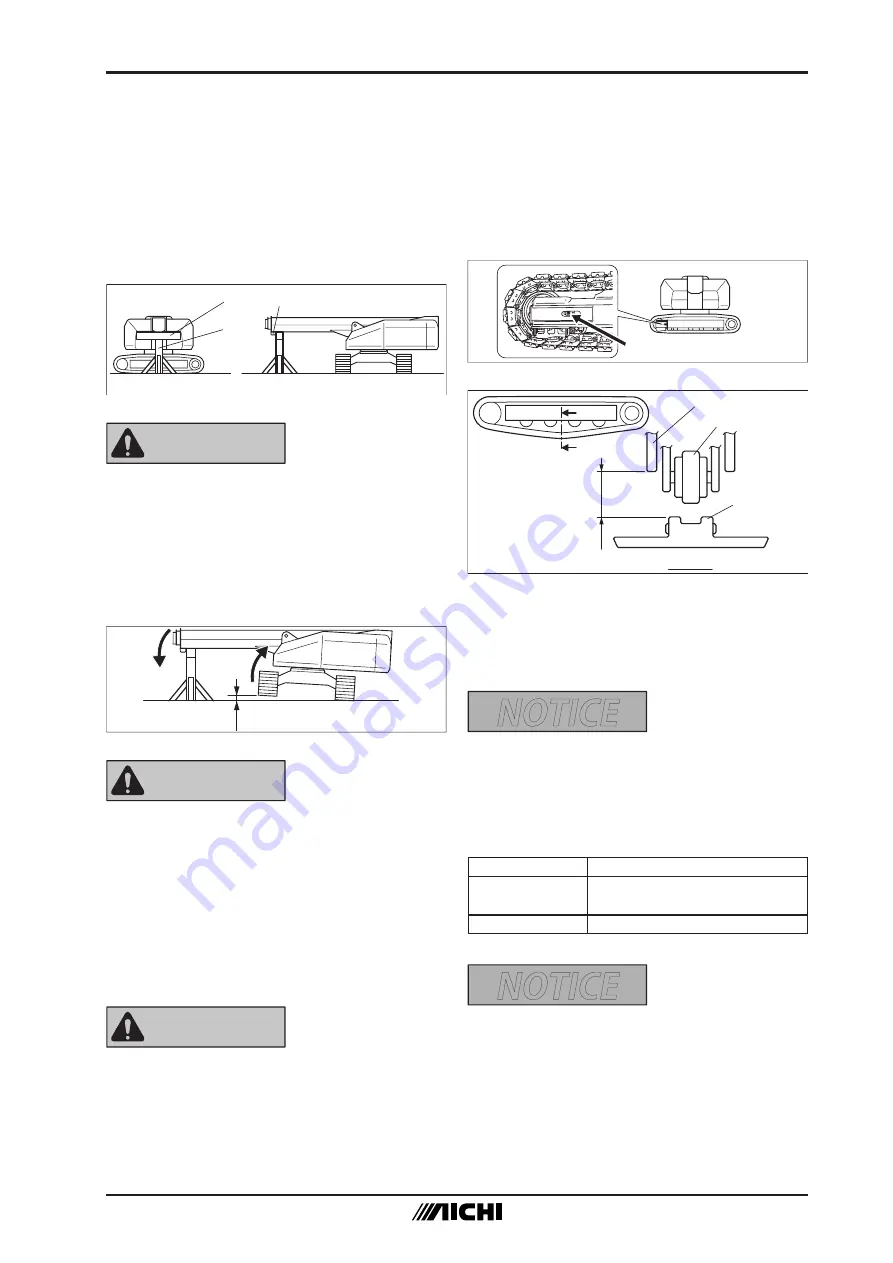

M085K320

Track roller

Chassis frame

115mm~125mm

A − A

Track link

A

A

fi g. 7‒9

After adjusting one side, rotate the boom

180 °

and adjust the other side in the same

manner.

NOTICE

It is important to adjust the tension of

left and right tracks equally.

Adjustment Interval

3‒2‒2

Adjust the tension of the tracks at the

following time intervals.

Interval

First time on

new machine

After 10 〜 20 hours

Thereafter

Every 800 hours or 6 months

table 7‒3

NOTICE

Confi rm the number of hours in service

by the hour meter.