10

SAWING METAL

When cutting angle metals such as channel

section, I-beam, etc., start the cut in a position

where the greatest number of teeth will contact

the work.

To extend blade life, cutting oil can be applied to

the work surface along the line of the cut.

MAINTENANCE

Every 50 hours of operation blow compressed

air through the motor while running at no load

to clean out accumulated dust. (If operating in

especially dusty conditions, perform this operation

more often.)

KEEP TOOL CLEAN

Periodically blow out all air passages with dry

compressed air. All plastic parts should be cleaned

with a soft damp cloth. NEVER use solvents to

clean plastic parts. They could possibly eat into or

dissolve the material.

Wear safety glasses while using compressed air

.

BRUSH INSPECTION

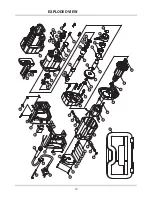

REPLACEMENT PARTS

When servicing use only identical replacement

parts.

SERVICE AND REPAIRS

All tools will eventually require servicing or

replacement of parts due to wear from normal use.

Always use a qualified service center. SERVICE

THE CARBON BRUSHES

The carbon brushes are a normal wearing part and

must be replaced when they reach their wear limit.

Caution: Always replace the brushes as a pair

To replace:

simply remove the brush caps and withdraw the

old brushes. Replace with new brushes (always

replace as a pair) ensuring that they align properly

and slide freely. Then replace the brush caps.

Note: If the brushes are only being checked,

then make sure to replace them in the same

position and orientation as before.

STANDARD ACCESSORIES

* 4 mm socket hex key

If the replacement of the power supply

cord is necessary, this has to be done by the

manufacturer or their agent in order to avoid a

safety hazard.

WARNING: All repairs must be entrusted to an

authorized service center.

Incorrectly performed

repairs could lead to injury or death.

Brush cap