18

S300S-S400S-S500S 10.01

5890940_03

By Aermec

• HYDRAULIC CONNECTION

For the position of the connections and

their function (see the specifications of

each storage tank) or the ones indicated

on the label applied at the back of each

storage tank.

Install the appliance near to the grea-

test drawing point of hot water in order

to avoid heat dispersion along the pipes

and possibly near to a drain to facilitate

any emptying operations.

- The cold water feeding duct must

have a safety valve mounted upstre-

am of the heat exchanger.

- The connection duct between the

heat exchanger and the safety valve

must not be intercepted because it

could damage the heat exchanger

as a result of overpressure.

Pay careful attention during the installa-

tion phase of the safety valve (Fig.2-pos.

A). Avoid forcing it at the end run and

tampering with it. The safety valve has

a nominal setting value of 8 bar. Slight

dripping from the safety valve is normal

during the heating phase; for this rea-

son, it should be connected to a siphon

drain.

In the case of a pressure network near

to the valve settings values, an adequate

pressure reducer must be applied (Fig.2-

pos. E), as far away as possible from the

appliance.

In the case that the system is equipped

with a pressure reducer, for the reasons

listed above, and/or a stop valve, an

expansion tank

must be installed

(Fig.2-

pos. D) with a capacity no less than 5%

of the nominal capacity for each heating

appliance.

No stop valve is necessary between the

expansion tank and the safety valve. In

general, the installation of an expansion

tank with the characteristics listed above

is advised in each case, to protect the

appliance and the network.

Inflate the appropriate membrane cham-

ber of the expansion tank according to

instructions from the manufacturer.

Before connecting the appliance to the

network, fill it completely with water as

follows:

• Open the cold water feeding cock;

• Open a hot water tap (e.g. bathroom,

sink etc.) in order to allow the dischar-

ge of air and wait for a constant flow of

water from all the hot water taps.

• Make sure there are not losses along

the various hydraulic connections.

In the presence of hard water with a

value of >20°TH (where 1°TH=French

degree=10mg CaCo3/l), install speci-

fic products that prevent excessive lime

scale precipitation.

Some devices are comparable to the one

way valve and therefore, to use them, an

adequate expansion tank must be instal-

led (see fig. 2).

The appliance is prearranged for con-

nection to a recirculation pipeline (Z): if

mounted, this conduct must be insulated.

For the functioning of recirculation (Z),

install a pump equipped with a timer fun-

ction or a minute counter thermostat, in

order to activate the cooling of the recir-

culation water.

To ensure the availability of hot water

when opening the taps, it is possible to

install a recirculation duct between the

feeding points and the recirculation tube

of the storage tank. This duct must be

provided with a one way valve.

In the case that the connection is not used,

provide with a seal plug. The inlet and out-

let ducts must be connected to the points

pre-determined by the heat exchanger.

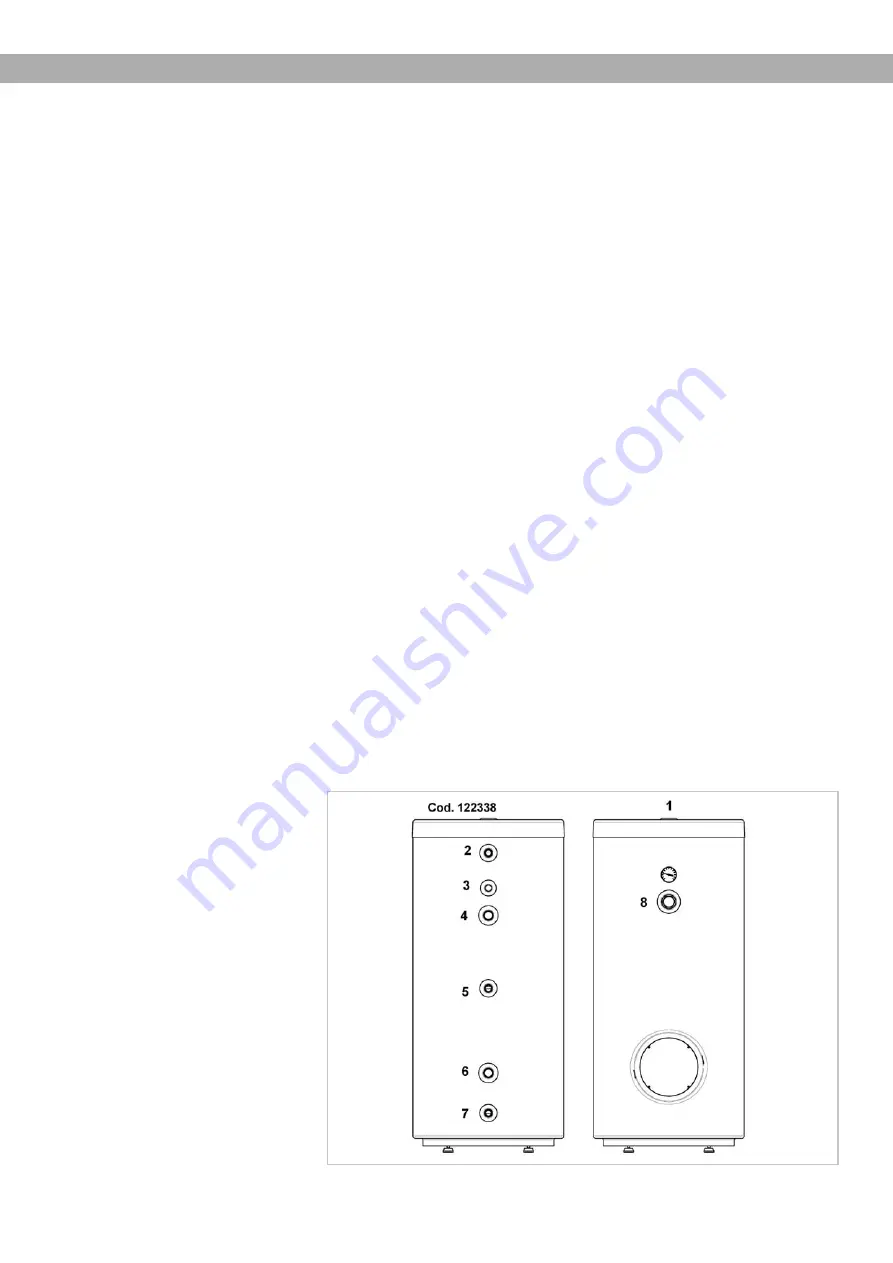

Legend

1. Magnesium anode

2. Hot water

3. Tube for sensor

4. Heat exchanger inlet

5. Recirculation

6. Heat exchanger outlet

7. Cold water

8. Attachment for Rp 1” ½ resistance

• Label