40

6. CYLINDER AND PISTON

6.1 SERVICE INFORMATION

6.2 TROUBLESHOOTING

6.3 CYLINDER REMOVAL

6.4 PISTON REMOVAL

6.5 PISTON INSTALLATION

6.6 CYLINDER INSTALLATION

6.1 SERVICE INFORMATION

GENERAL

Camshaft lubrication oil is fed to the cylinder head through an oil orifice in the cylinder head

and engine case. Before installing the cylinder head be sure the orifice is not clogged and the

gasket, O-ring and dowel pins are in place.

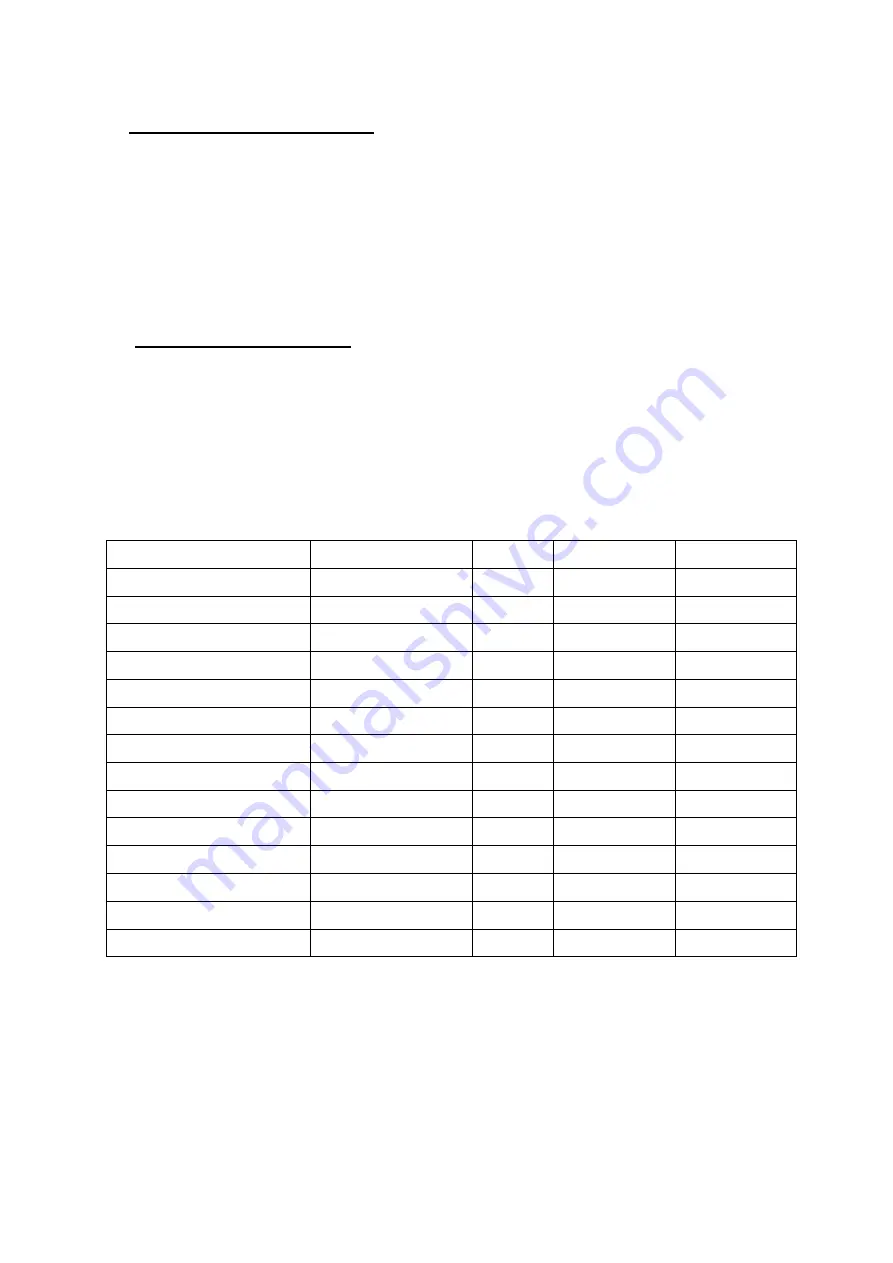

SPECIFICATION

ITEM

STANDARD

SERVICE

LIMIT

Cylinder I.D.

65-65.01

----------

Taper

----------

0.05

Out of round

----------

0.05

Warp

across

top

----------

0.05

Piston Piston

O.D.

64.96-64.98

----------

Piston pin

Piston pin bore

15.997-16

----------

Piston rings

Piston pin O.D.

14.994-15.000

14.960

Piston-to-pin

clearance

0.004-0.012

----------

Piston

ring

TOP

0.1-0.25

0.5

SECOND

0.3-0.45

0.5

Groove

Clearance

TOP/SEC

0.02-0.06

0.09

Piston ring end gap

OIL

0.2-0.7

1.5

Cylinder-to-piston clearance

0.02-0.05

0.1

Connecting rod small end I.D.

16.01-16.028

----------

TORQUE VALUES

Cylinder head bolts 8~12 n-m (0.8~1.2 kg-m)

Camshaft holder flange nuts 20~24 n-m (2.0~2.4 kg-m)

Tappet adjusting nut 9~12 n-m (0.9~1.2 kg-m)

Содержание Cobra 220

Страница 1: ...AEON MOTOR CO LTD SERVICE MANUAL...

Страница 29: ...28 7 Install the oil pump galley 8 Install flywheel key flywheel washer and nut 9 Install stator housing...

Страница 63: ...62...