4

• To contstuct a working prototype of the intake system, it is best to cut the tubing to

an approximate size leaving a little extra at the ends of the bends. Use the couplers

to connect the pipes. For the blade style MAF sensor, use double sided foam tape to

attach the MAF pad to the pipe so that it can be easily relocated if the fuel trims are

unacceptable. Once the configuration of the system is complete, and the fuel trims

are acceptable, the mounting bracket can be mounted, and if applicable the MAF pad

can be welded to the inlet tube.

• With the AEM universal intake we provide two couplers AEM-5-438 for installation

using a tubular MAF sensor. We also Provide a weld on aluminum MAF pad for the

blade style MAF sensor.

• The routing of the inlet system must be clear of any moving engine component.

Additionally, before making the inlet tract permanent, Perform an “engine rock “ test

to ensure there is no contact with the body or chassis when the engine torques over

when under load. This check is done by starting the engine and putting it in gear

WITH THE PARKING BRAKE ON AND THE BRAKES APPLIED. Raise the engine speed in

forward and then reverse gear to 2000 RPM and having someone observe there is no

contact with any part of the vehicle including hoses or wiring of any kind.

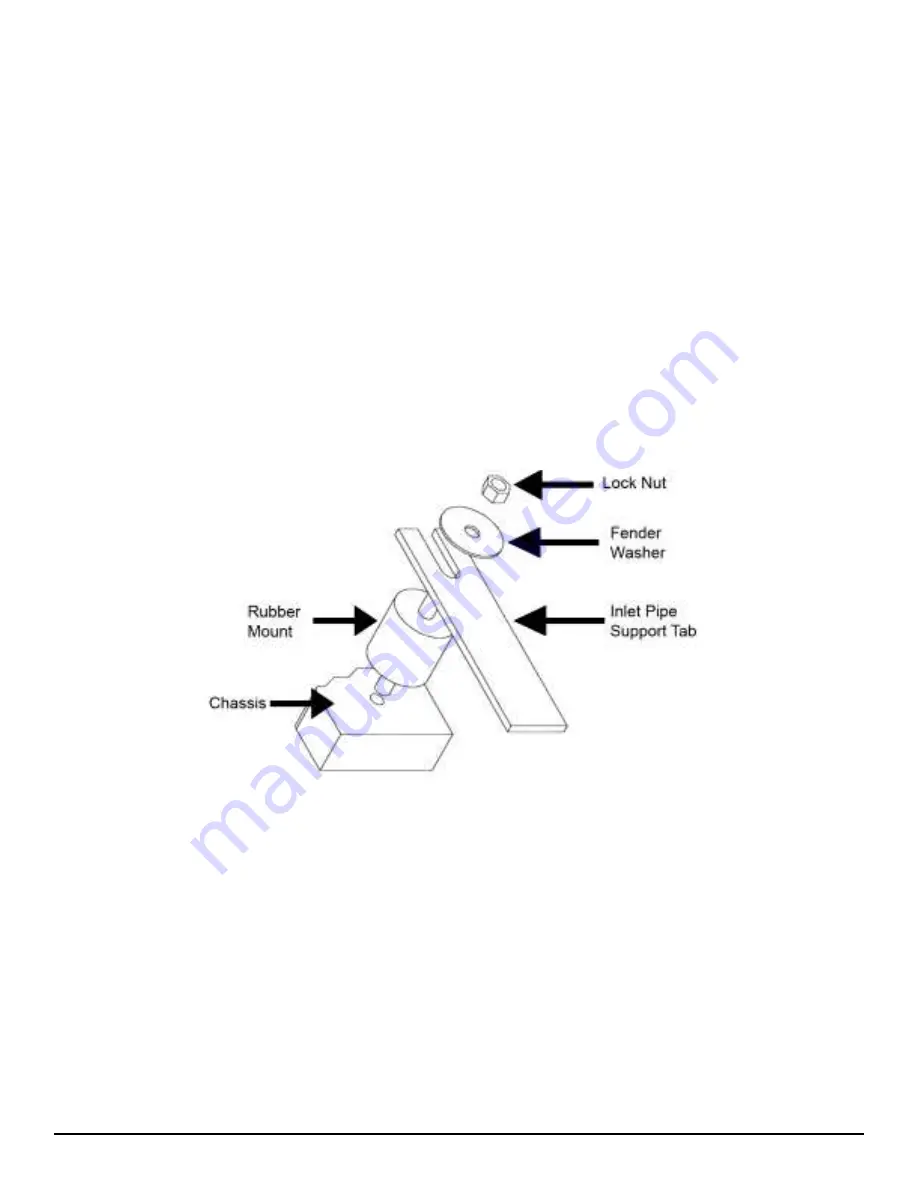

• The location of the mounting bracket used to stabilize the inlet duct should be placed

as close to the filter end of the intake tube as possible to minimize the moment load

at the weld attachment point on the duct.

• There is a rubber soft mount included with the kit to isolate the movement of the

intake tube from the body of the vehicle. This mount MUST be used to ensure the

mount bracket does not crack.